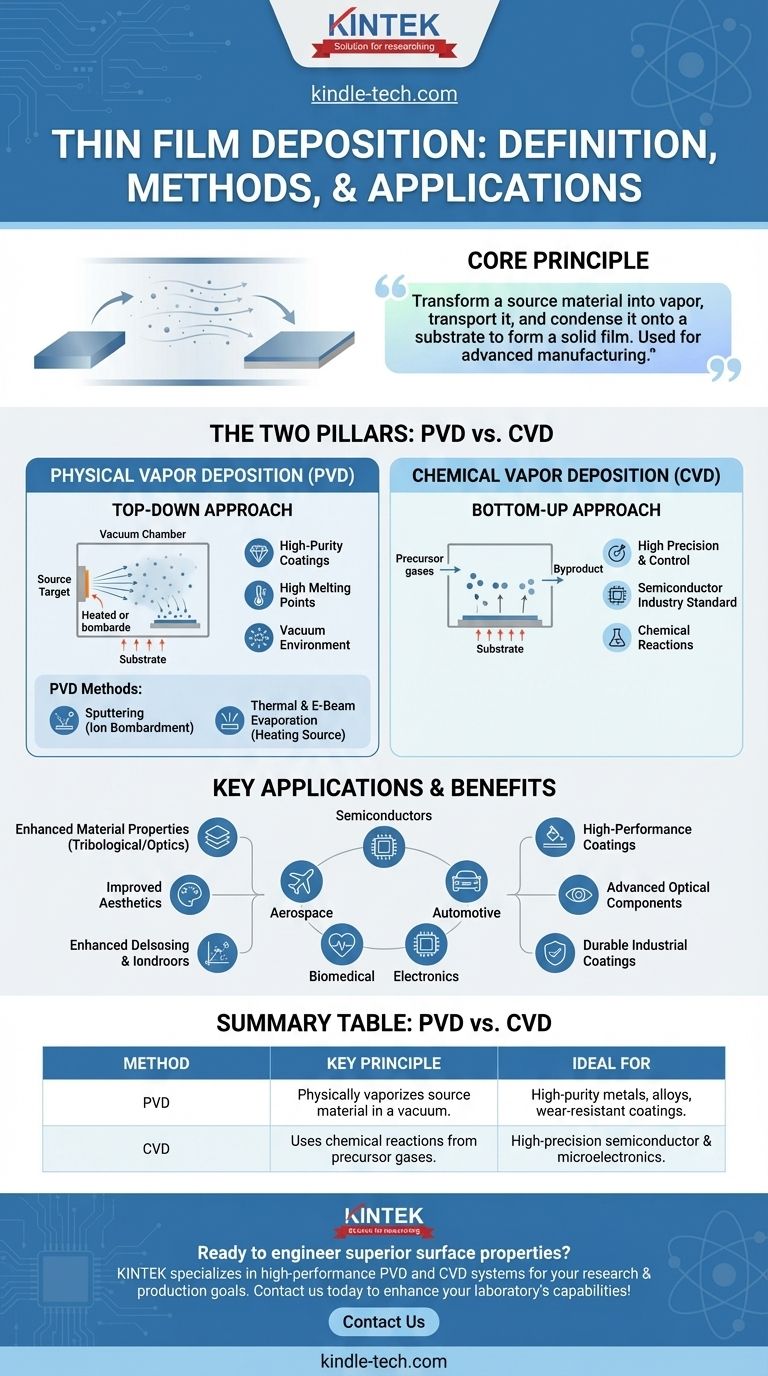

In essence, thin film deposition is a set of processes used to apply an extremely thin layer of material, often just a few atoms or molecules thick, onto a surface called a substrate. These methods are fundamental to manufacturing advanced products, from computer chips to solar panels, by giving the substrate new physical or chemical properties.

The core principle of thin film deposition is to transform a source material into a vapor, transport it, and then condense it onto a substrate to form a solid film. The two dominant methods to achieve this are Physical Vapor Deposition (PVD), which uses physical means like evaporation, and Chemical Vapor Deposition (CVD), which uses chemical reactions.

The Two Pillars of Deposition: PVD vs. CVD

At a high level, all thin film deposition techniques fall into one of two major categories: Physical Vapor Deposition (PVD) or Chemical Vapor Deposition (CVD). The choice between them is driven by the material being deposited and the desired properties of the final film.

Physical Vapor Deposition (PVD)

PVD is a "top-down" approach where a solid or liquid source material is physically transformed into a vapor, which then condenses onto the substrate. This process is always conducted in a vacuum to prevent the vapor from reacting with air.

PVD is typically used for materials with high melting points and when a high-purity coating is required.

Chemical Vapor Deposition (CVD)

CVD is a "bottom-up" approach where precursor gases are introduced into a chamber. These gases react or decompose on the surface of the substrate to create the desired solid film.

CVD is the most commonly used method in the semiconductor industry because it offers exceptionally high precision and control over the film's structure and thickness.

A Closer Look at PVD Methods

Because PVD encompasses several distinct techniques, it's helpful to understand the most common ones. The primary goal is always to generate atomic particles from a source target that can then coat the substrate.

Sputtering

Sputtering, sometimes called cathodic spraying, involves bombarding the source material (the "target") with high-energy ions. This collision physically knocks atoms loose from the target, which then travel and deposit onto the substrate.

Thermal & E-Beam Evaporation

Evaporation involves heating a source material until it reaches its boiling point and turns into a vapor. This vapor then travels through the vacuum chamber and condenses on the cooler substrate, forming the film. The heating can be done with a thermal source or a more focused electron beam (e-beam).

Understanding the Trade-offs

Choosing the right deposition method is a critical decision based on balancing cost, material properties, and the final application's requirements.

When to Choose CVD

CVD is the preferred method when precision is paramount. Its ability to grow a film atom-by-atom makes it ideal for the complex, layered structures found in microelectronics and semiconductors.

When to Choose PVD

PVD methods like sputtering are often chosen for depositing pure metals, alloys, and certain ceramic compounds. They are excellent for applications requiring hard, wear-resistant, or optically-specific coatings on tools, glass, and other components.

The Critical Role of the Source

Regardless of the method, the choice of the deposition source itself is key. Sources can include ion beams, magnetron sputtering cathodes, or thermal evaporators. The selection depends entirely on the materials you need to deposit and the final film characteristics you want to achieve.

Why This Process Matters: Key Applications

Thin film deposition is not an academic exercise; it is a foundational technology that enables a vast range of modern products and industries.

Enhancing Material Properties

A primary goal of deposition is to change the surface properties of an object. This includes improving tribological behavior (wear and friction resistance), enhancing optics (like anti-reflective coatings on lenses), or simply upgrading the aesthetics of a product.

Enabling Modern Technology

The impact of thin film deposition is widespread across numerous fields. It is essential for the semiconductor, aerospace, automotive, biomedical, and electronics industries, forming the basis for integrated circuits, durable engine components, and medical implants.

Making the Right Choice for Your Goal

To select the appropriate method, you must first define your primary objective.

- If your primary focus is extreme precision and conformity for electronics: CVD is the established industry standard for its atomic-level control.

- If your primary focus is creating a high-purity or high-melting-point coating: A PVD method like sputtering or e-beam evaporation is your most direct and effective path.

- If your primary focus is a specific functional property like wear resistance: The choice will be driven by the specific material required for that property, which in turn will dictate whether a PVD or CVD process is more suitable.

Ultimately, mastering thin film deposition is about using atomic-scale engineering to build macro-scale performance.

Summary Table:

| Method | Key Principle | Ideal For |

|---|---|---|

| PVD (Physical Vapor Deposition) | Physically vaporizes a source material in a vacuum to coat a substrate. | High-purity metals, alloys, and wear-resistant coatings. |

| CVD (Chemical Vapor Deposition) | Uses chemical reactions from precursor gases to grow a film on a substrate. | High-precision applications in semiconductors and microelectronics. |

Ready to engineer superior surface properties with the right thin film deposition method?

At KINTEK, we specialize in providing high-performance lab equipment, including PVD and CVD systems, tailored to your specific research and production goals. Whether you are developing advanced semiconductors, durable industrial coatings, or cutting-edge optical components, our expertise ensures you achieve precise, reliable, and high-quality results.

Contact us today to discuss how our solutions can enhance your laboratory's capabilities and drive your innovations forward.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- Can plasma enhanced CVD deposit metals? Why PECVD is rarely used for metal deposition

- Why is a Matching Network Indispensable in RF-PECVD for Siloxane Films? Ensure Stable Plasma and Uniform Deposition

- What is the difference between PECVD and APCVD? Choose the Right CVD Method for Your Application

- What are the process capabilities of ICPCVD systems? Achieve Low-Damage Film Deposition at Ultra-Low Temperatures

- What are different types of thin films? A Guide to Function, Material, and Deposition Methods