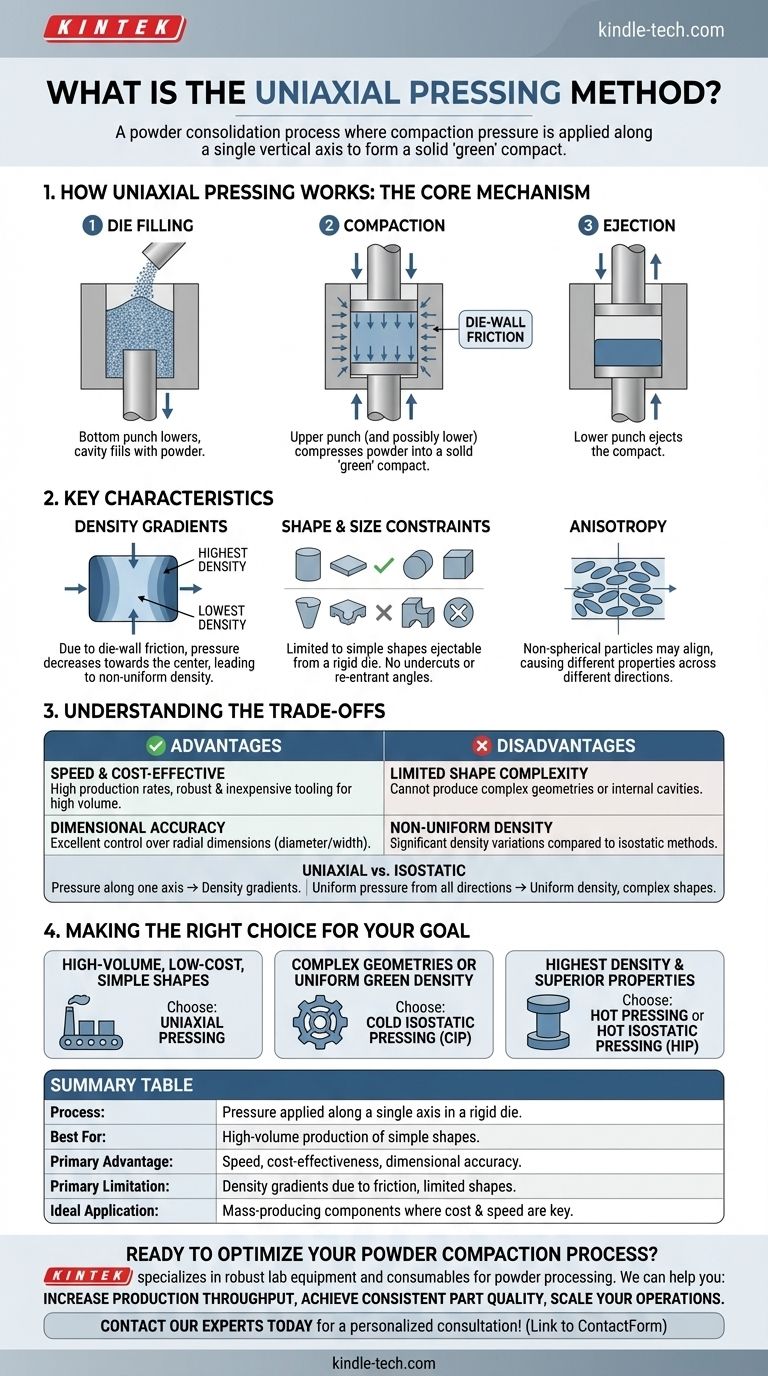

In essence, uniaxial pressing is a powder consolidation process where compaction pressure is applied along a single vertical axis. In this method, a precise amount of powder is loaded into a rigid die cavity and then compressed by one or more moving punches to form a solid, albeit porous, object known as a "green" compact.

Uniaxial pressing is the workhorse of powder processing, prized for its speed and cost-effectiveness in mass-producing simple shapes. Its fundamental limitation, however, is the creation of density variations within the part due to friction, which restricts its use for complex geometries or applications requiring perfect uniformity.

How Uniaxial Pressing Works: The Core Mechanism

To understand the capabilities and limitations of this method, you must first understand its mechanics. The process is a straightforward cycle of filling, compressing, and ejecting.

The Setup: Die, Punches, and Powder

The core tooling consists of a rigid die, which defines the outer shape of the final part, and one or two punches that fit precisely within the die. In a single-action press, only the top punch moves. In a more common double-action press, both the top and bottom punches move, which helps to improve density uniformity.

The Pressing Cycle

The process unfolds in three distinct steps:

- Die Filling: The bottom punch is lowered to create a cavity, which is then filled with a specific volume of granulated powder.

- Compaction: The upper punch descends into the die, applying force to the powder. In a double-action press, the bottom punch may also rise simultaneously. This pressure forces the powder particles into a denser arrangement, creating a solid "green" compact.

- Ejection: The upper punch retracts, and the bottom punch pushes the newly formed compact up and out of the die cavity.

The Role of Friction

During compaction, a critical event occurs: die-wall friction. As the punches apply pressure, the powder particles not only press against each other but also against the stationary walls of the die. This friction opposes the applied force, causing the pressure to diminish as it travels deeper into the powder bed.

Key Characteristics of Uniaxially Pressed Parts

The mechanics of the process directly influence the final properties of the component. The most significant characteristic is the non-uniformity of density.

Density Gradients: The Primary Limitation

Because of die-wall friction, the pressure is highest near the faces of the moving punches and lowest in the middle of the compact, especially near the die wall. This results in predictable density gradients. The areas with lower density will shrink differently during the subsequent sintering (firing) step, which can lead to warping or cracking.

Shape and Size Constraints

The geometry of a uniaxially pressed part is limited to shapes that can be easily ejected from a rigid die. This means no undercuts, cross-holes, or re-entrant angles. The process is best suited for parts with a consistent cross-section along the pressing axis, such as cylinders, bushings, and simple tiles. The aspect ratio (height-to-diameter) is also a critical factor; very tall, thin parts are difficult to produce due to severe density gradients.

Anisotropy

If the starting powder contains non-spherical particles (like flakes or rods), the pressing action can cause them to align perpendicularly to the pressing direction. This alignment can lead to anisotropy, where the mechanical or thermal properties of the final part are different in the pressing direction compared to the radial direction.

Understanding the Trade-offs: Uniaxial vs. Other Methods

Choosing uniaxial pressing is a decision based on balancing speed, cost, and component requirements. Its value becomes clear when compared to alternative methods like isostatic pressing.

Advantage: Speed and Cost-Effectiveness

Uniaxial presses are highly automated and can achieve very high production rates (hundreds or even thousands of parts per hour). The tooling is robust and relatively inexpensive compared to more complex methods, making it the most economical choice for high-volume manufacturing.

Advantage: Dimensional Accuracy

The use of a rigid steel die provides excellent control over the radial dimensions (the diameter or width) of the part. This precision minimizes the need for subsequent machining operations on those surfaces.

Disadvantage: Limited Shape Complexity

This is the most significant trade-off. Isostatic pressing, where pressure is applied uniformly from all directions via a fluid, can produce highly complex shapes with undercuts and internal cavities that are impossible with uniaxial pressing.

Disadvantage: Non-Uniform Density

Again, compared to isostatic pressing (both cold and hot), uniaxial pressing produces parts with significant density variations. For high-performance applications where uniform material properties are critical (e.g., aerospace or medical implants), isostatic methods are superior.

Making the Right Choice for Your Goal

Selecting the correct powder consolidation method requires a clear understanding of your project's priorities. The trade-off is almost always between production efficiency and component perfection.

- If your primary focus is high-volume, low-cost production of simple shapes: Uniaxial pressing is the definitive and most logical choice.

- If your primary focus is creating complex geometries or achieving uniform density in a green part: You must use Cold Isostatic Pressing (CIP).

- If your primary focus is achieving the highest possible final density and superior mechanical properties: You should consider Hot Pressing or Hot Isostatic Pressing (HIP), which combine pressure and temperature.

By understanding these fundamental trade-offs, you can confidently select the most effective consolidation method for your material and manufacturing goals.

Summary Table:

| Aspect | Key Characteristic |

|---|---|

| Process | Pressure applied along a single axis in a rigid die |

| Best For | High-volume production of simple shapes (e.g., cylinders, tiles) |

| Primary Advantage | Speed, cost-effectiveness, and excellent radial dimensional accuracy |

| Primary Limitation | Density gradients due to die-wall friction, restricting shape complexity |

| Ideal Application | Mass-producing components where cost and speed outweigh the need for perfect density uniformity |

Ready to optimize your powder compaction process?

Uniaxial pressing is a powerful solution for high-volume manufacturing, but selecting the right equipment is critical for success. KINTEK specializes in providing robust and efficient lab equipment and consumables tailored to your powder processing needs.

We can help you:

- Increase production throughput with reliable uniaxial pressing systems.

- Achieve consistent part quality with precision tooling and expert guidance.

- Scale your operations with solutions designed for laboratory and industrial environments.

Whether you're working with advanced ceramics, metal powders, or other materials, our expertise ensures you get the right technology for your goals.

Contact our experts today for a personalized consultation and discover how KINTEK's solutions can enhance your laboratory's efficiency and output.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

People Also Ask

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples