At its core, a furnace chamber is a precisely controlled environment designed for high-temperature thermal processing. Its primary use is to fundamentally alter the physical or chemical properties of materials by applying heat in a specific, repeatable manner for functions like sintering, annealing, drying, and curing.

The essential purpose of a furnace chamber is to serve as the insulated workspace where materials are subjected to extreme heat. This controlled heating enables a vast range of processes, from creating new materials in a lab to strengthening metal components for industrial machinery.

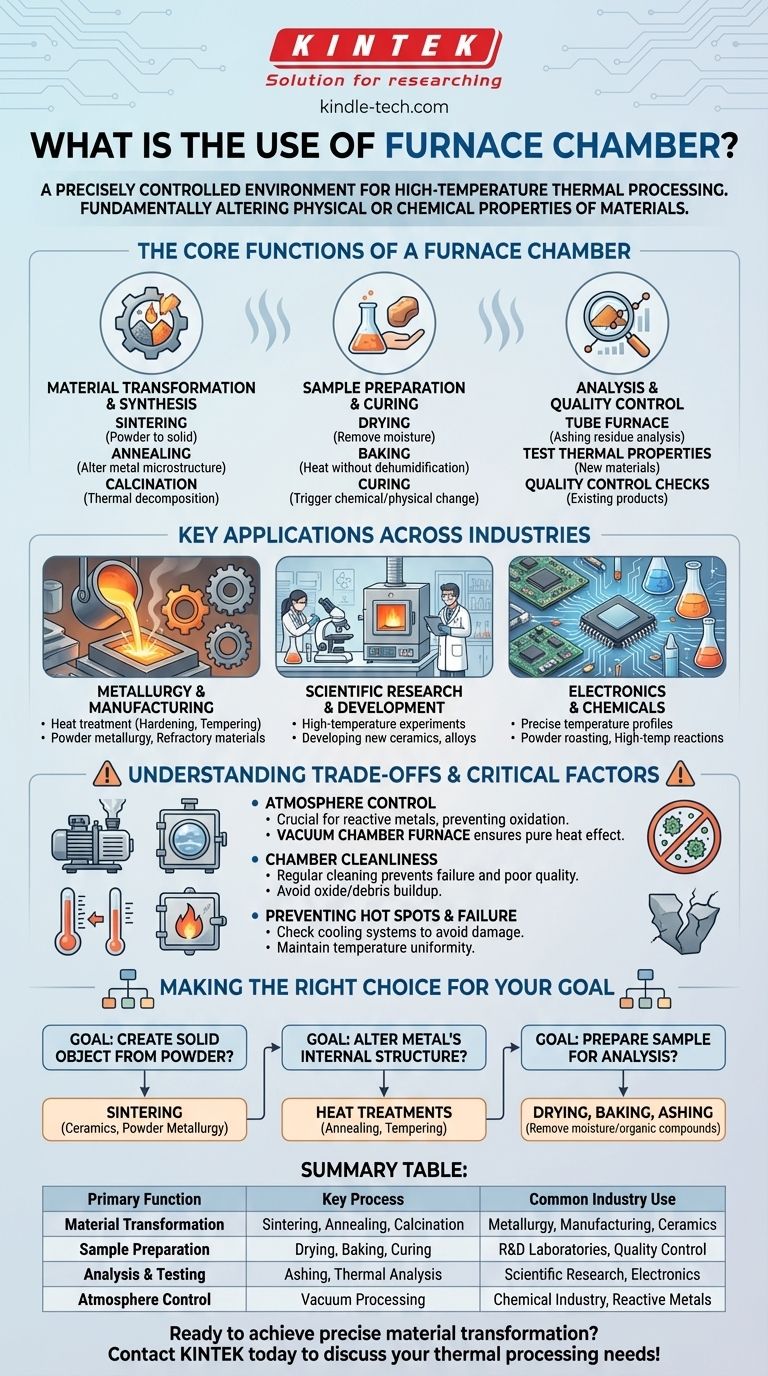

The Core Functions of a Furnace Chamber

A furnace chamber isn't just a hot box; it's an instrument for targeted material transformation. The specific function depends entirely on the material being processed and the desired outcome.

Material Transformation and Synthesis

The most significant use of a furnace chamber is to change a material's fundamental state. This includes processes like sintering, where powdered materials (like ceramics or metals) are heated until their particles fuse together into a solid object.

Other key transformations include annealing, which alters a metal's microstructure to make it softer and less brittle, and calcination, which uses heat to cause thermal decomposition.

Sample Preparation and Curing

In laboratory and industrial settings, furnace chambers are critical for preparing samples. This can involve simple drying to remove all moisture or baking to heat a sample without dehumidification.

The chamber is also used for curing, a process where heat triggers a chemical or physical change, such as hardening a coating, adhesive, or composite material.

Analysis and Quality Control

In research and development, furnaces are used for analysis. A tube furnace, for example, can be used to analyze the residue of ashed materials after combustion.

This allows scientists and engineers to test the thermal properties of new materials or perform quality control checks on existing products.

Key Applications Across Industries

The versatility of the furnace chamber makes it indispensable in nearly every technical field that deals with physical materials.

Metallurgy and Manufacturing

In metallurgy, furnaces are used for the heat treatment of metals. This includes hardening, tempering, and annealing steel to achieve specific mechanical properties.

They are also foundational to powder metallurgy, manufacturing, and processing refractory materials that must withstand extreme temperatures.

Scientific Research and Development

Universities, R&D institutes, and labs rely on furnaces for high-temperature experiments. These controlled environments are essential for developing and testing new ceramics, alloys, and special materials.

Electronics and Chemicals

The production of many electronic components, glass, and ceramics requires the precise temperature profiles provided by a furnace chamber.

In the chemical industry, they are used for everything from powder roasting to facilitating specific high-temperature chemical reactions.

Understanding the Trade-offs and Critical Factors

While powerful, the effectiveness of a furnace chamber is dependent on its design and maintenance. Neglecting key factors can lead to failed processes and damaged equipment.

The Importance of Atmosphere Control

Many heat treatment processes, especially for reactive metals, require a controlled atmosphere to prevent oxidation. This is where a vacuum chamber furnace is used.

By removing air and other gases, the vacuum ensures the material is only affected by the heat, not by unwanted chemical reactions with its environment.

The Critical Need for Chamber Cleanliness

A furnace chamber must be kept impeccably clean. Oxides, debris, or contaminants left over from a previous cycle can ruin the next process.

Operators should regularly remove any buildup. A contaminated chamber can lead to failed experiments, poor material quality, and inaccurate results.

Preventing Hot Spots and Component Failure

Proper maintenance extends beyond just cleaning. Scorch marks, or hot spots, on the chamber walls indicate improper cooling, which can damage the furnace and the sample.

Ensuring the cooling water systems are functioning correctly is essential to prevent clogging or corrosion of critical components and maintain temperature uniformity.

Making the Right Choice for Your Goal

The specific process you use depends entirely on your objective. Understanding your end goal is the key to leveraging the furnace chamber effectively.

- If your primary focus is creating a solid object from powder: You need to use a sintering process, which is fundamental in ceramics and powder metallurgy.

- If your primary focus is altering a metal's internal structure (e.g., softening or hardening): Your goal will be achieved through heat treatments like annealing or tempering.

- If your primary focus is preparing a sample for laboratory analysis: Your core functions will be drying, baking, or ashing to remove moisture or organic compounds.

Ultimately, mastering the furnace chamber is about understanding how to use controlled heat to manipulate matter with intention and precision.

Summary Table:

| Primary Function | Key Process | Common Industry Use |

|---|---|---|

| Material Transformation | Sintering, Annealing, Calcination | Metallurgy, Manufacturing, Ceramics |

| Sample Preparation | Drying, Baking, Curing | R&D Laboratories, Quality Control |

| Analysis & Testing | Ashing, Thermal Analysis | Scientific Research, Electronics |

| Atmosphere Control | Vacuum Processing | Chemical Industry, Reactive Metals |

Ready to achieve precise material transformation in your lab?

A properly selected and maintained furnace chamber is critical for successful sintering, annealing, and curing processes. KINTEK specializes in providing high-performance lab furnaces and consumables tailored to your specific research and production goals.

Our experts can help you choose the right equipment to ensure temperature uniformity, atmosphere control, and reliable results.

Contact KINTEK today to discuss your thermal processing needs and enhance your laboratory's capabilities!

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vertical Laboratory Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Controlled Nitrogen Inert Hydrogen Atmosphere Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What materials are used for the tubes in tube furnaces? A Guide to Selecting the Right Tube for Your Process

- How does a high-temperature tube furnace facilitate the phase transformation of alumina products? Master Thermal Control

- What is the primary advantage of using a tube furnace? Achieve Superior Temperature and Atmosphere Control

- How to clean a tube furnace? A Step-by-Step Guide for Safe and Effective Maintenance

- What is the technical value of using a quartz tube reaction chamber for static corrosion testing? Achieve Precision.