At its core, a pyrolysis plant is a facility for chemical recycling. It uses high heat in an oxygen-free environment to break down complex waste materials—like plastics, tires, or biomass—and convert them into valuable new substances such as fuel oil, combustible gas, and a carbon-rich solid called char.

A pyrolysis plant fundamentally solves a waste problem by transforming it into a resource opportunity. Instead of sending materials to a landfill, it decomposes them into marketable products, primarily for energy generation and industrial applications.

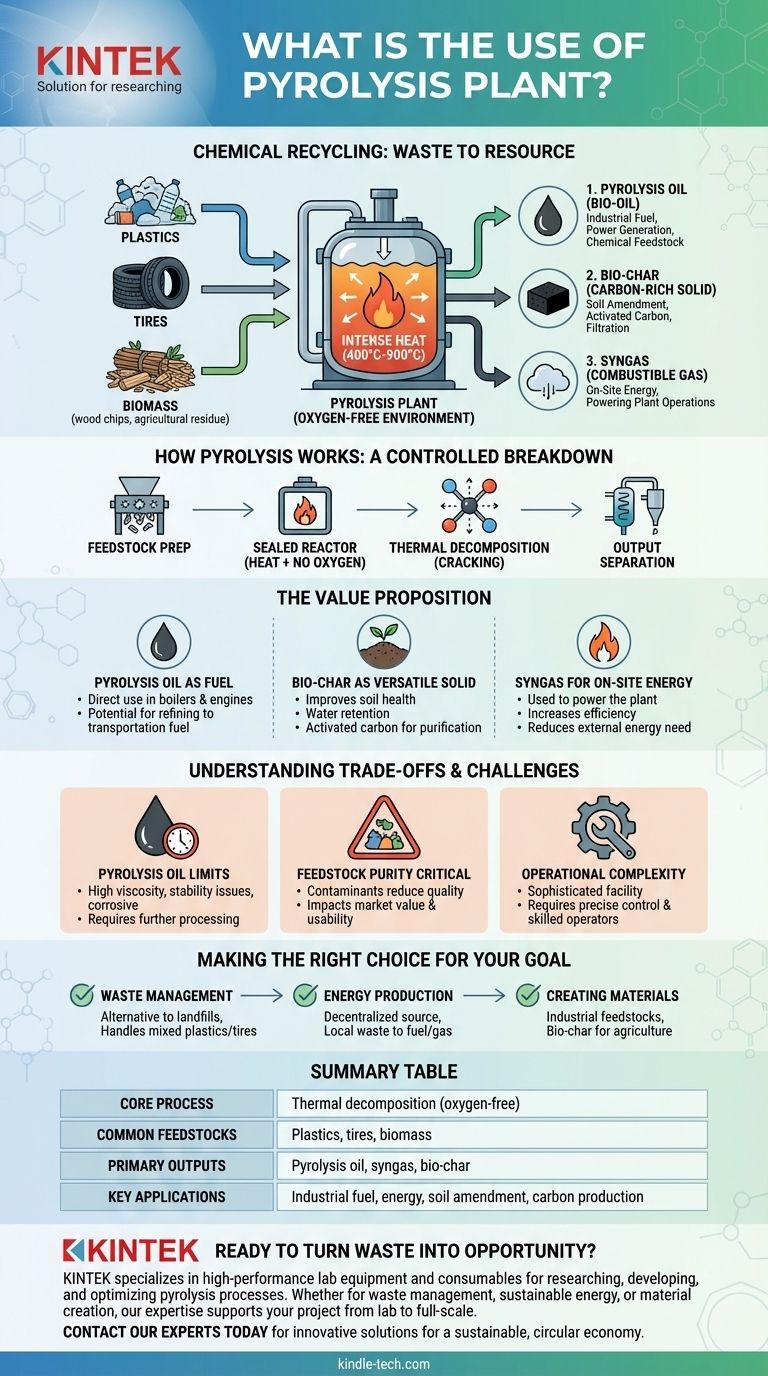

How Pyrolysis Works: A Controlled Breakdown

Pyrolysis is a process of thermal decomposition. It is fundamentally different from incineration because the absence of oxygen prevents the material from burning. Instead, the intense heat breaks the complex molecular bonds of the feedstock.

The Core Principle: Heat Without Oxygen

Materials like plastics or old tires are fed into a sealed reactor. This reactor is then heated to extreme temperatures, typically between 400°C and 900°C. Without oxygen, the material "cracks," breaking down into simpler, smaller molecules that exist as gases, liquids, and solids.

The Common Feedstocks

While many organic materials can undergo pyrolysis, plants are often specialized. The most common feedstocks include plastic waste, scrap tires, and biomass such as wood chips or agricultural residue. The type of input material directly influences the properties of the final products.

The Three Key Outputs

The process consistently yields three primary products:

- Pyrolysis Oil (Bio-oil): A liquid fuel similar to conventional fuel oil.

- Bio-Char: A stable, carbon-rich solid.

- Syngas (Synthesis Gas): A mixture of combustible gases.

The Value Proposition: From Waste to Resource

Each output from a pyrolysis plant has distinct applications, turning what was once considered garbage into a valuable commodity for various industries.

Pyrolysis Oil as a Fuel Source

This liquid product can be used directly as a fuel in industrial boilers, furnaces, diesel engines, and large power plants as a substitute for conventional fuel oil. It can also be upgraded or refined to produce higher-grade transportation fuels or serve as a chemical feedstock.

Bio-Char as a Versatile Solid

When derived from biomass, bio-char is an excellent soil amendment, improving soil structure, water retention, and nutrient availability. It can also be processed into activated carbon, a critical material used in filtration and purification systems.

Syngas for On-Site Energy

The mixture of gases produced is flammable. In most modern pyrolysis plants, this syngas is captured and used to power the plant itself, significantly reducing external energy consumption and making the entire operation more efficient and sustainable.

Understanding the Trade-offs and Challenges

While pyrolysis technology offers a powerful solution, it is not without its complexities and limitations. Objectivity requires acknowledging these operational realities.

The Limits of Pyrolysis Oil

Direct industrial application of pyrolysis oil can be challenging. The oil often has high viscosity, lower stability over time, and can be corrosive to standard equipment. This means it frequently requires further processing or specialized hardware for effective use.

Feedstock Purity is Critical

The efficiency of the plant and the quality of its outputs are highly dependent on the input material. Contaminated or mixed feedstocks can lead to lower-quality oil and char, impacting their market value and usability.

Operational Complexity

A pyrolysis plant is a sophisticated industrial facility. It requires precise control systems, robust safety measures, and skilled operators to manage the high temperatures and pressures involved, ensuring both efficiency and safety.

Making the Right Choice for Your Goal

The "use" of a pyrolysis plant depends entirely on the primary problem you are trying to solve.

- If your primary focus is waste management: Pyrolysis is a powerful alternative to landfills, especially for difficult-to-recycle materials like mixed plastics and vehicle tires.

- If your primary focus is energy production: The plant functions as a decentralized energy source, converting local waste into fuel oil and gas that can power industrial operations or generate electricity.

- If your primary focus is creating valuable materials: Pyrolysis is a production method for generating industrial feedstocks, bio-char for agriculture, and raw materials for specialty chemical production.

Ultimately, a pyrolysis plant acts as a crucial technology bridge, closing the loop between waste disposal and sustainable resource creation.

Summary Table:

| Aspect | Details |

|---|---|

| Core Process | Thermal decomposition of waste in an oxygen-free environment. |

| Common Feedstocks | Plastic waste, scrap tires, biomass (wood chips, agricultural residue). |

| Primary Outputs | Pyrolysis oil, syngas (combustible gas), bio-char (carbon-rich solid). |

| Key Applications | Industrial fuel, on-site energy generation, soil amendment, activated carbon production. |

Ready to turn your waste management challenge into a resource opportunity?

A pyrolysis plant is a sophisticated solution for converting difficult-to-recycle materials into valuable commodities. At KINTEK, we specialize in providing the high-performance lab equipment and consumables necessary for researching, developing, and optimizing pyrolysis processes.

Whether you are focused on waste management, sustainable energy production, or creating valuable industrial materials, our expertise can support your project from the lab to full-scale operation.

Contact our experts today to discuss how KINTEK's solutions can power your pyrolysis innovation and help you achieve a sustainable, circular economy.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

People Also Ask

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products

- What are the different types of pyrolysis machines? Choose the Right System for Your Output