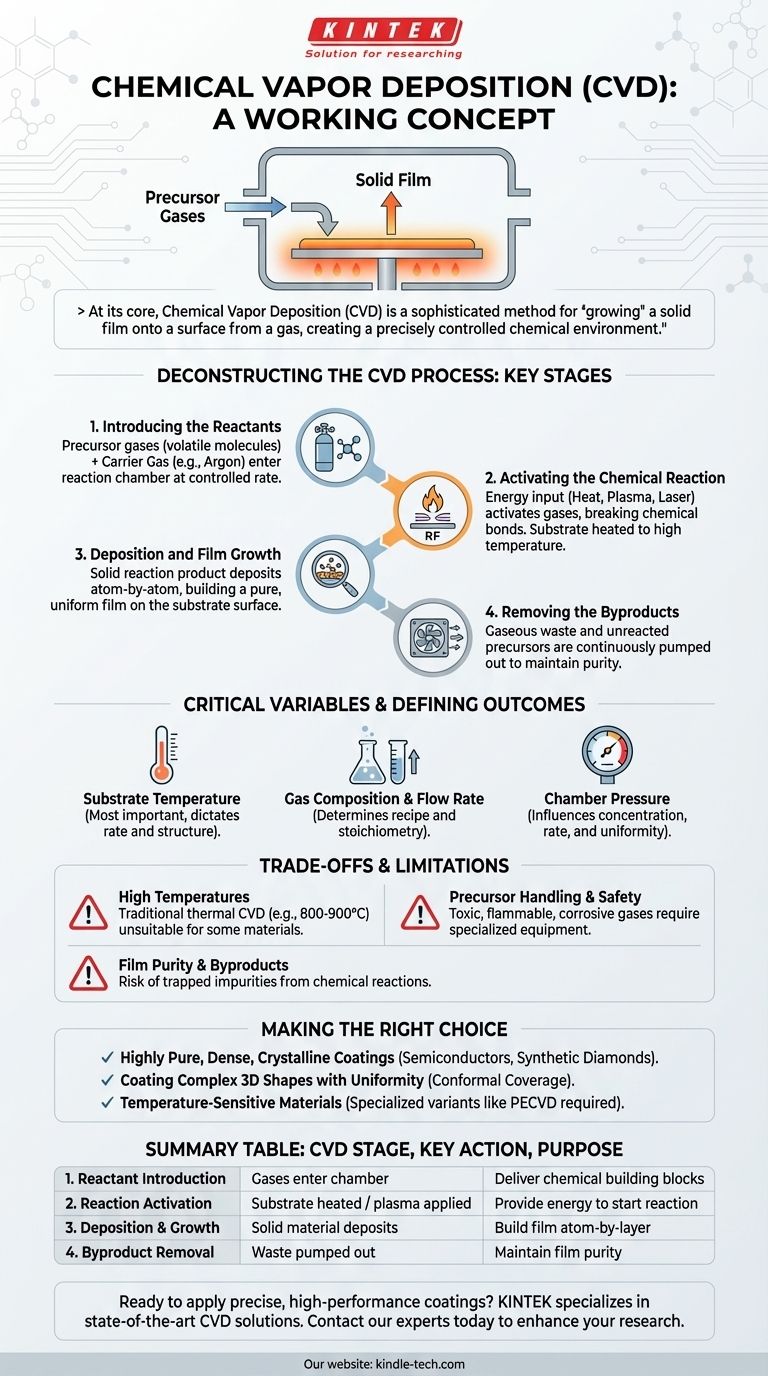

At its core, Chemical Vapor Deposition (CVD) is a sophisticated method for 'growing' a solid film onto a surface from a gas. The process involves introducing volatile precursor gases, which contain the constituent elements of the desired film, into a reaction chamber. When these gases come into contact with a heated substrate, they undergo a chemical reaction, causing the desired solid material to deposit onto the substrate's surface, forming a thin, uniform coating.

The fundamental concept of CVD is not to spray a pre-made material, but to create a precisely controlled chemical environment. In this environment, thermal energy forces gaseous molecules to react and assemble themselves, atom by atom, into a solid film on a target surface.

Deconstructing the CVD Process: The Key Stages

To understand how CVD works, it's best to break it down into a sequence of distinct, controlled stages. Each stage plays a critical role in the quality and properties of the final film.

Stage 1: Introducing the Reactants

The process begins with one or more precursor gases being fed into a reaction chamber at a controlled rate.

These are not the final coating material itself, but rather volatile molecules that contain the necessary atoms. For example, to create a pure carbon film like a diamond, a carbon-rich gas like methane (CH₄) is used.

Often, these reactive gases are diluted with an inert carrier gas (like argon or nitrogen) to help transport them smoothly over the substrate.

Stage 2: Activating the Chemical Reaction

For the precursor gases to react and deposit a solid, they need an input of energy.

The most common method is heating the substrate to a high temperature, often several hundred degrees Celsius. This thermal energy provides the activation energy needed to break the chemical bonds in the gas molecules.

In some advanced CVD processes, energy is supplied by other means, such as an RF plasma or lasers, which can initiate the reaction at lower temperatures.

Stage 3: Deposition and Film Growth

As the energized gas molecules pass over the hot substrate, the chemical reaction occurs on or very near its surface.

The solid product of this reaction deposits onto the substrate, building up a film. This is an atomistic process, meaning the film grows layer by layer, which allows for highly pure and well-structured (crystalline) materials.

The substrate itself can sometimes act as a catalyst, promoting the chemical reaction and ensuring the resulting film adheres strongly to the surface.

Stage 4: Removing the Byproducts

The chemical reactions are rarely 100% efficient and produce gaseous byproducts in addition to the solid film.

These waste gases, along with any unreacted precursor gases, are continuously pumped out of the chamber. This exhaust process is crucial for preventing impurities from being incorporated into the growing film.

The Critical Variables That Define the Outcome

The final properties of the deposited film are not accidental; they are the direct result of carefully managing several key parameters.

Substrate Temperature

This is arguably the most important variable. The temperature dictates the rate of the chemical reaction and the final structure of the film. Too low, and the reaction won't occur; too high, and you may get poor quality or unwanted side reactions.

Gas Composition and Flow Rate

The "recipe" of the film is determined by the types of precursor gases and their flow rates. The ratio of different gases controls the chemical composition (stoichiometry) of the final material.

Chamber Pressure

The pressure inside the reaction chamber affects the concentration of gas molecules and how they travel. This, in turn, influences the deposition rate and the uniformity of the coating, especially on complex-shaped objects.

Understanding the Trade-offs and Limitations

While powerful, CVD is not without its challenges. Understanding its limitations is key to using it effectively.

The Need for High Temperatures

Traditional thermal CVD often requires very high temperatures (e.g., 800-900°C for diamond growth). This makes it unsuitable for coating materials with low melting points or those that could be damaged by heat, such as many plastics and complex electronics.

Precursor Handling and Safety

The precursor gases used in CVD can be highly toxic, flammable, or corrosive. This necessitates specialized, expensive equipment for handling, storage, and safety, which adds complexity to the process.

Film Purity and Byproducts

Because the process is a chemical reaction, it's possible for unwanted byproducts to become trapped in the film as impurities. Preventing this requires precise control over all process variables.

Making the Right Choice for Your Goal

Deciding to use CVD depends entirely on the requirements of your final product.

- If your primary focus is creating a highly pure, dense, and crystalline coating: CVD is an exceptional choice, as its atom-by-atom growth mechanism is ideal for high-performance applications like semiconductor wafers and synthetic diamonds.

- If your primary focus is coating a complex 3D shape with a uniform film: The gaseous nature of the precursors allows them to penetrate and coat intricate surfaces conformally, something that line-of-sight processes cannot do.

- If you are working with temperature-sensitive materials: You must investigate specialized, lower-temperature CVD variants, such as Plasma-Enhanced CVD (PECVD), to avoid damaging your substrate.

Ultimately, understanding CVD is about mastering the controlled chemistry required to build high-performance materials from the ground up.

Summary Table:

| CVD Stage | Key Action | Purpose |

|---|---|---|

| 1. Reactant Introduction | Precursor gases enter the chamber. | Deliver the chemical building blocks for the film. |

| 2. Reaction Activation | Substrate is heated or plasma is applied. | Provide energy to break chemical bonds and start the reaction. |

| 3. Deposition & Growth | Solid material deposits on the substrate surface. | Build the film atom-by-layer for high purity and structure. |

| 4. Byproduct Removal | Gaseous waste is pumped out. | Maintain film purity by removing reaction contaminants. |

Ready to apply precise, high-performance coatings to your components?

The controlled environment of a CVD system is key to creating highly pure, uniform, and durable thin films for semiconductors, optics, and advanced materials. KINTEK specializes in providing state-of-the-art lab equipment and consumables to meet your specific laboratory needs.

Contact our experts today to discuss how our CVD solutions can enhance your research and development process.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- How do PECVD systems improve DLC coatings on implants? Superior Durability and Biocompatibility Explained

- Why is a Matching Network Indispensable in RF-PECVD for Siloxane Films? Ensure Stable Plasma and Uniform Deposition

- Can plasma enhanced CVD deposit metals? Why PECVD is rarely used for metal deposition

- What are different types of thin films? A Guide to Function, Material, and Deposition Methods

- What is the difference between plasma CVD and thermal CVD? Choose the Right Method for Your Substrate