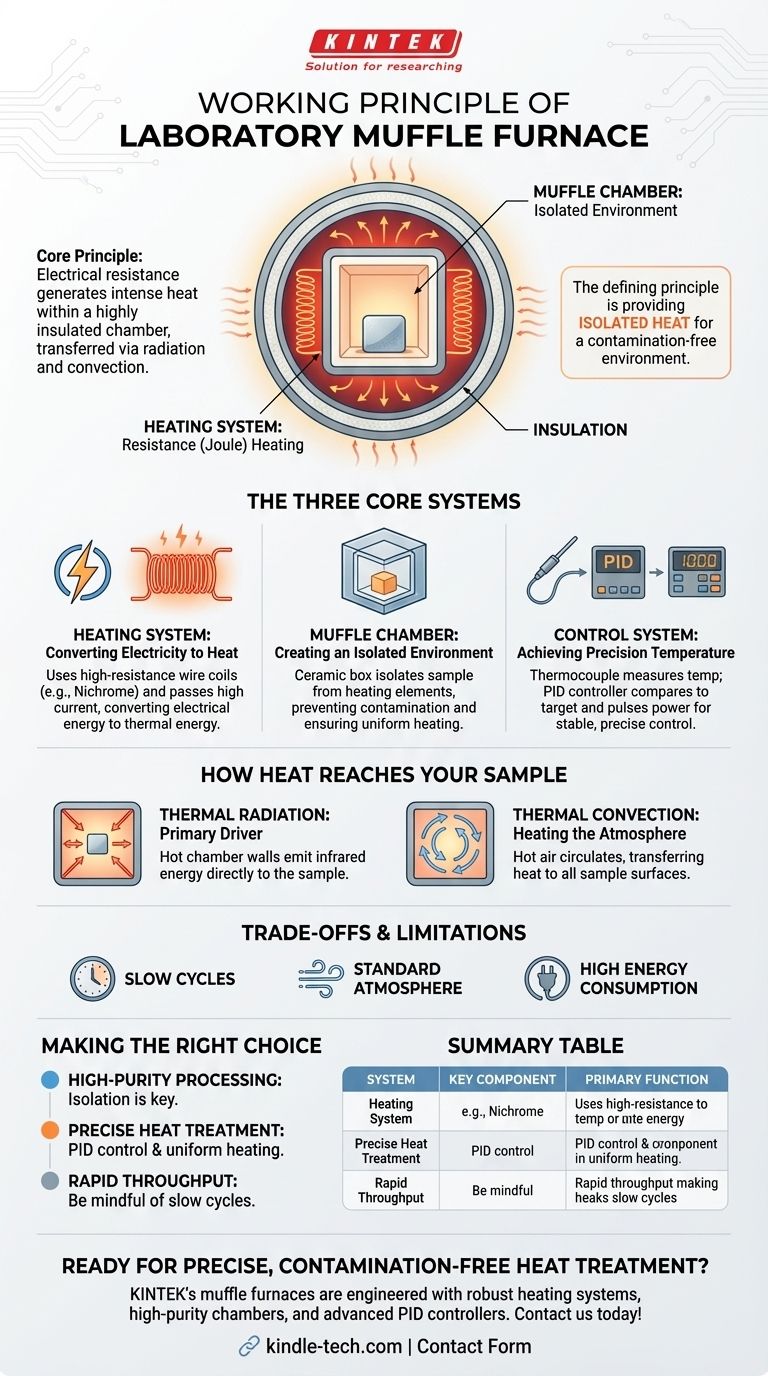

At its core, a laboratory muffle furnace operates by using electrical resistance to generate intense heat within a highly insulated chamber. This heat is transferred to the object inside primarily through thermal radiation and convection. The "muffle" itself is the inner chamber, which isolates the sample from the heating elements, ensuring a clean, uniform, and controlled high-temperature environment.

The defining principle of a muffle furnace isn't just its ability to achieve high temperatures, but its capacity to provide isolated heat. By separating the sample within the muffle, it creates a highly controlled and contamination-free environment essential for precise scientific and industrial work.

The Three Core Systems of a Muffle Furnace

To truly understand the working principle, it's best to break the furnace down into its three interconnected systems: the heating system, the muffle chamber, and the control system.

The Heating System: Converting Electricity to Heat

A modern muffle furnace is an electric device that operates on the principle of resistance heating, also known as Joule heating.

High-resistance wire coils, often made of a Nichrome or similar alloy, are mounted around the outside of the inner chamber.

When a high electric current is passed through these coils, their inherent resistance causes them to become extremely hot, converting electrical energy directly into thermal energy.

The Muffle Chamber: Creating an Isolated Environment

The "muffle" is the central component from which the furnace gets its name. It is a box-like chamber made of a high-purity, heat-resistant ceramic or refractory material.

Its primary function is to isolate the workpiece from the actual heating elements. This prevents any direct contamination and ensures the sample is heated uniformly from all sides rather than by direct contact with a red-hot coil.

This chamber is surrounded by thick layers of high-performance insulation, which prevents heat from escaping and allows the furnace to maintain extremely high temperatures efficiently.

The Control System: Achieving Precision Temperature

A muffle furnace would be useless without precise control. This is achieved through a sophisticated electronic feedback loop.

A temperature sensor, typically a thermocouple, is placed inside the chamber to constantly measure the internal temperature.

This reading is sent to a PID (Proportional-Integral-Derivative) controller. This is the "brain" of the furnace, which compares the actual temperature to the user-set target temperature.

Based on the difference, the PID controller intelligently pulses power to the heating elements using a solid-state relay (SSR) or contactor, ensuring the temperature doesn't overshoot the target and remains stable.

How Heat Reaches Your Sample

Once heat is generated, it must be transferred to the material inside the muffle. This happens through two primary mechanisms.

Thermal Radiation: The Primary Driver

As the walls of the muffle chamber heat up to extreme temperatures, they emit powerful thermal radiation (infrared energy).

This energy travels through the air in the chamber and is absorbed by the surface of your sample, heating it directly and uniformly without physical contact. This is the same way the sun heats the Earth.

Thermal Convection: Heating the Atmosphere

The air trapped inside the sealed chamber is also heated by the hot walls. This hot air circulates in convection currents, transferring additional heat to all surfaces of the sample. While radiation is the dominant force at very high temperatures, convection ensures even heating, especially during the initial warm-up phase.

Understanding the Trade-offs and Limitations

While powerful, the design of a muffle furnace comes with inherent characteristics you must understand.

Slow Heating and Cooling Cycles

The same heavy insulation that makes the furnace so energy-efficient at maintaining temperature also gives it significant thermal mass. This means it takes a considerable amount of time to both heat up to its target temperature and, more importantly, to cool down safely.

Standard Atmospheric Conditions

A standard muffle furnace heats samples in the presence of air (an oxygen-rich atmosphere). This is ideal for processes like ashing, sintering, or certain heat treatments. However, it is unsuitable for materials that would oxidize at high temperatures. For those applications, a specialized vacuum or inert gas furnace is required.

High Energy Consumption

Achieving and maintaining temperatures of 1000°C or higher requires a substantial amount of electrical power. This is a practical consideration for both utility costs and the electrical infrastructure of your lab.

Making the Right Choice for Your Application

Understanding these principles allows you to use the furnace effectively for your specific goal.

- If your primary focus is high-purity material processing or ashing: The isolation provided by the muffle is its most critical feature, as it prevents contamination from the heating elements.

- If your primary focus is precise heat treatment of metals or ceramics: The PID control system and uniform radiant heating are key, ensuring your material reaches the exact target temperature without hot spots.

- If your primary focus is rapid sample throughput: Be mindful of the slow heating and cooling cycles, as this will likely be the main bottleneck in your workflow.

By understanding these core principles, you can leverage the muffle furnace as a precise tool for materials transformation, not just a simple hot box.

Summary Table:

| System | Key Component | Primary Function |

|---|---|---|

| Heating | Resistance Wire Coils (e.g., Nichrome) | Converts electricity into intense heat via Joule heating. |

| Chamber | Ceramic Muffle & Insulation | Isolates the sample for contamination-free, uniform heating. |

| Control | Thermocouple & PID Controller | Precisely measures and maintains the target temperature. |

| Heat Transfer | Thermal Radiation & Convection | Ensures the sample is heated evenly from all sides. |

Ready to achieve precise, contamination-free heat treatment in your lab?

KINTEK's muffle furnaces are engineered with the precise principles outlined above—featuring robust heating systems, high-purity ceramic chambers, and advanced PID controllers for unparalleled temperature control and uniformity. Whether your application is ashing, sintering, or heat-treating metals and ceramics, our equipment ensures reliable, repeatable results.

Contact us today using the form below to discuss your specific laboratory needs. Our experts will help you select the ideal furnace to enhance your research and quality control processes.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- How does tempering reduce hardness? Achieve the Perfect Balance of Toughness and Durability

- What are furnaces usually made of? A Guide to Materials for Extreme Temperatures

- What is the relationship between sintering temperature and melting temperature? Key Differences for Material Engineers

- What is the most common metal used for blacksmithing? Start with Mild Steel for Forging Success

- What PPE is required for a muffle furnace? Essential Gear for High-Temperature Safety