At its core, thermal evaporation is a method for creating thin films by heating a source material inside a high-vacuum chamber until it vaporizes. This vapor then travels through the vacuum and condenses onto a cooler surface, or substrate, forming a uniform coating. Because the heat is generated by passing an electrical current through a resistive element holding the material, it is also frequently called resistive evaporation.

This technique is best understood as a highly controlled version of boiling water. Just as boiling water creates steam that condenses on a cool surface, thermal evaporation creates a material vapor that condenses into a solid thin film, making it a straightforward and cost-effective process for many applications.

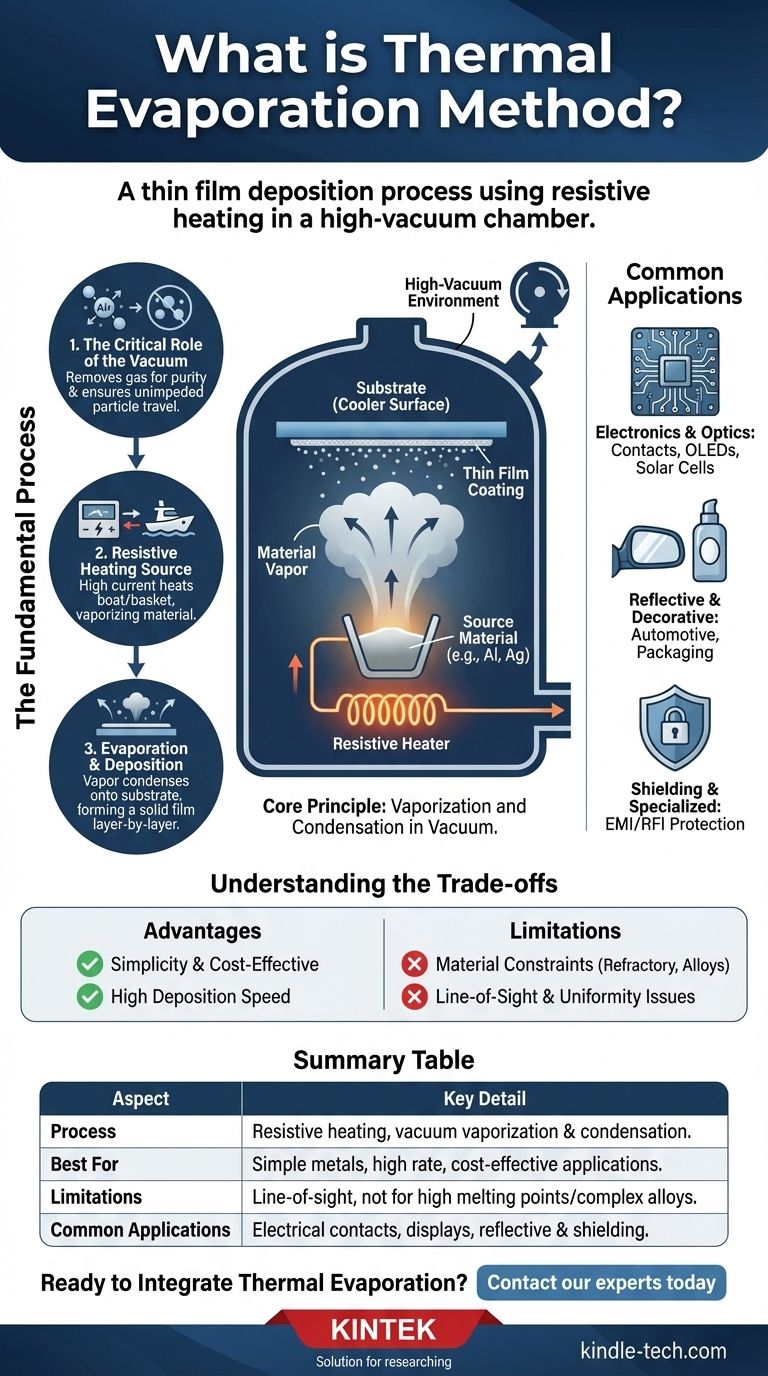

The Fundamental Process: From Solid to Film

To truly understand thermal evaporation, it's essential to break down the environment and the sequence of events that enable the creation of a thin film.

The Critical Role of the Vacuum

The entire process occurs in a high-vacuum chamber. This is not arbitrary; the vacuum serves two critical functions.

First, it removes air and other gas molecules that could react with the hot vapor, ensuring the purity of the final film.

Second, it allows the vaporized atoms to travel directly to the substrate without colliding with other particles. This unimpeded, line-of-sight path is crucial for effective deposition.

The Resistive Heating Source

The source material, often in the form of pellets or wire, is placed in a container called a "boat" or "basket." This boat is typically made of a refractory metal like tungsten or molybdenum.

A high electrical current is passed through the boat, causing it to heat up rapidly due to its electrical resistance. This heat is then transferred to the source material.

Evaporation and Deposition

As the source material's temperature rises to its evaporation point, its atoms gain enough energy to escape into the gaseous phase, creating a vapor cloud.

This vapor expands throughout the chamber, eventually reaching the cooler substrate (e.g., a silicon wafer, glass, or plastic part) that is strategically placed above the source. Upon contact, the vapor atoms lose their energy, condense back into a solid state, and build up layer-by-layer to form a thin film.

Common Applications Across Industries

The simplicity and versatility of thermal evaporation make it a go-to choice for a wide range of uses, from basic research to high-volume manufacturing.

Electronics and Optics

This method is a staple for creating electrical contacts on devices by depositing single metals like aluminum or silver. It is also used in the production of thin-film devices such as OLED displays and solar cells.

Reflective and Decorative Coatings

Thermal evaporation is widely used to deposit thin layers of metal, like aluminum, onto surfaces to create highly reflective coatings. This is common in light reflectors for the automotive, medical, and aerospace industries. It is also used for decorative finishes on items like cosmetic packaging and sporting goods.

Shielding and Specialized Films

Thin metallic films deposited via thermal evaporation can provide effective EMI/RFI shielding for sensitive electronic components, protecting them from electromagnetic interference.

Understanding the Trade-offs

No single technique is perfect for every scenario. As a trusted method, thermal evaporation's strengths are balanced by clear limitations.

Key Advantage: Simplicity and Cost

Compared to more complex deposition systems, thermal evaporators are relatively simple in design and operation. This makes them less expensive to acquire and maintain, offering an accessible entry point for thin-film research and production.

Key Advantage: Deposition Speed

For many materials, especially simple metals, thermal evaporation offers a high deposition rate. This speed makes it highly efficient for applications where throughput is a primary concern.

Major Limitation: Material Constraints

The technique is not suitable for materials with very high melting points (refractory materials), as it can be difficult to generate enough heat. It also struggles with compound materials or alloys where different elements evaporate at different rates, which would result in a film with a different composition than the source material.

Major Limitation: Film Quality and Uniformity

Because the vapor travels in a straight line, it is a line-of-sight deposition method. This can create "shadows" on complex, three-dimensional substrates, leading to uneven coating. The resulting films can also be less dense and have lower adhesion compared to those produced by higher-energy processes like sputtering.

Making the Right Choice for Your Goal

Selecting a deposition method depends entirely on your material, budget, and desired film characteristics.

- If your primary focus is rapid prototyping or depositing simple metal contacts: Thermal evaporation is an excellent, cost-effective, and efficient choice.

- If your primary focus is creating high-purity, dense films or complex alloys: You should explore alternative methods like magnetron sputtering or atomic layer deposition.

- If your primary focus is large-scale decorative or reflective coatings: Thermal evaporation provides a fast, reliable, and well-established process for these high-volume applications.

By understanding these core principles and trade-offs, you can confidently determine if thermal evaporation is the appropriate technique for your specific material and performance requirements.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Process | Resistive heating in a vacuum vaporizes a source material, which condenses on a substrate. |

| Best For | Simple metals (Al, Ag), high deposition rates, cost-effective prototyping, and decorative coatings. |

| Limitations | Line-of-sight deposition (poor step coverage), not ideal for high-melting-point materials or complex alloys. |

| Common Applications | Electrical contacts, OLED displays, solar cells, reflective coatings, and EMI shielding. |

Ready to Integrate Thermal Evaporation into Your Lab Workflow?

KINTEK specializes in providing high-quality lab equipment and consumables for all your thin-film deposition needs. Whether you are prototyping new electronic devices or scaling up production for reflective coatings, our thermal evaporation systems offer the reliability and performance your laboratory requires.

Contact our experts today to discuss how our solutions can enhance your research and development process.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

- Electron Beam Evaporation Coating Conductive Boron Nitride Crucible BN Crucible

- Custom PTFE Teflon Parts Manufacturer for Culture Dish and Evaporation Dish

People Also Ask

- What are the effects of temperature and pressure on evaporation? Mastering Control for Your Process

- What is the difference between sputtering and evaporation techniques? A Guide to Choosing the Right PVD Method

- What is the difference between sputtering and evaporation deposition? A Guide to Choosing the Right PVD Method

- What is the thermal evaporation technique? A Guide to Thin-Film Deposition for Your Lab

- What is the beam deposition process? Achieve Ultra-Pure, High-Precision Thin Films

- What is the difference between thermal and e-beam evaporation? Choose the Right PVD Method for Your Lab

- What is the temperature of e-beam evaporation? Mastering the Two-Zone Thermal Process for Precision Films

- What is thermal evaporation deposition pressure? Master the Key to High-Quality Thin Films