In the simplest terms, thermal vapor deposition is a manufacturing process that creates ultra-thin films by heating a solid material in a vacuum until it turns into a vapor. This vapor then travels and condenses onto a cooler surface, known as a substrate, forming a precise and uniform coating.

At its core, thermal vapor deposition is a physical vapor deposition (PVD) technique analogous to boiling water. By "boiling" a material in a vacuum, its resulting "steam" or vapor can be used to apply an atom-by-atom layer onto a target, building a highly controlled thin film.

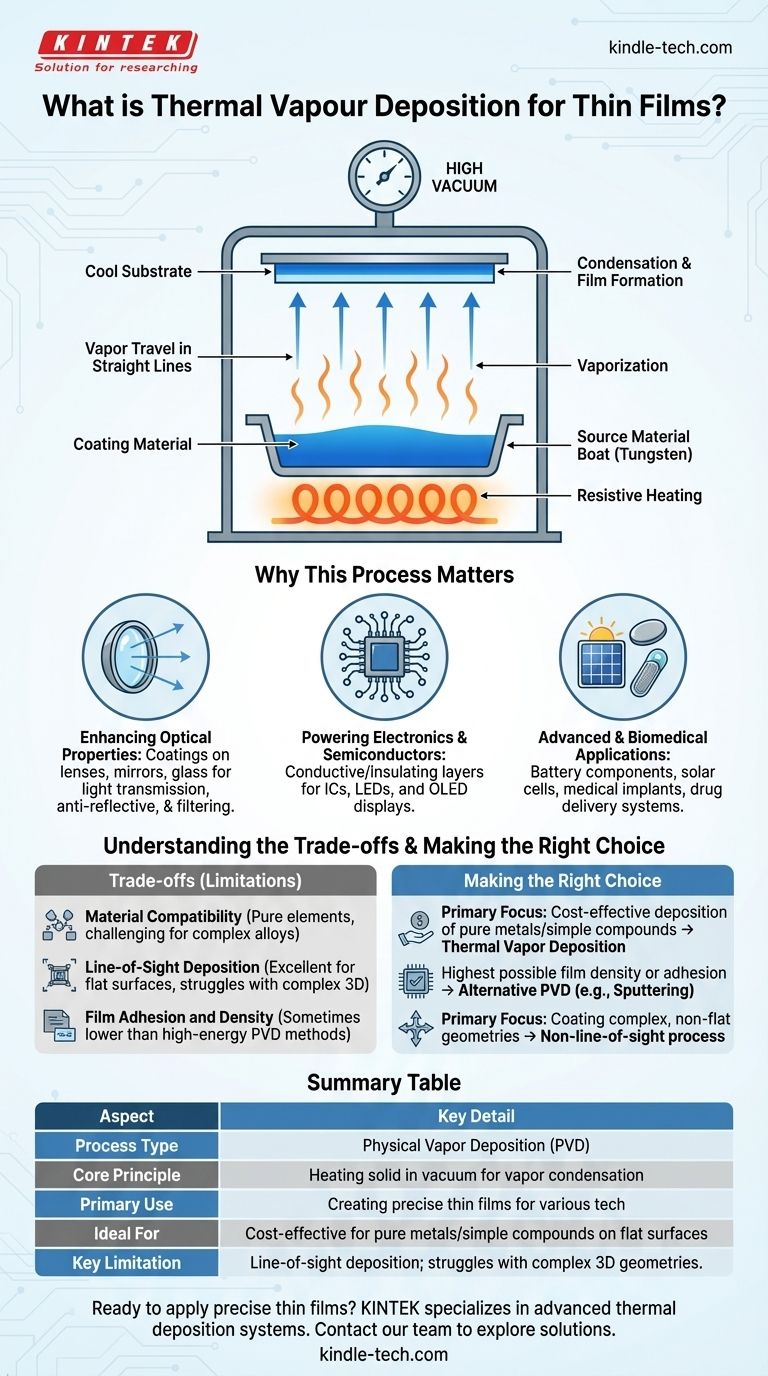

How Thermal Vapor Deposition Works: A Step-by-Step View

The elegance of thermal deposition lies in its straightforward physical principles. The entire process takes place inside a sealed high-vacuum chamber to ensure the purity and quality of the final film.

The Vacuum Environment

First, a high vacuum is created within the chamber. This is critical because it removes air and other gas molecules that could otherwise react with the hot vapor or interfere with its path to the substrate.

The Heating Process

The coating material, often called the source material, is placed in a container. This container, sometimes called a 'boat' or 'basket,' is made from a material like tungsten that can withstand extreme heat.

An electrical current is passed through this container, causing it to heat up resistively. This heat is transferred directly to the source material.

Vaporization and Travel

As the source material's temperature rises significantly, it begins to sublimate or evaporate, transitioning directly from a solid into a gaseous vapor.

Because the chamber is under vacuum, these vaporized atoms travel in straight lines from the source toward the target substrate with minimal obstruction.

Condensation and Film Formation

When the hot vapor atoms strike the relatively cool surface of the substrate, they rapidly lose energy and condense back into a solid state. This atom-by-atom accumulation gradually builds the desired thin film on the substrate's surface.

The Purpose of Thin Films: Why This Process Matters

The ability to create these precise, thin layers is fundamental to countless modern technologies. The properties of a material's surface can be completely transformed without changing the bulk material itself.

Enhancing Optical Properties

Thin films are used to create specialized optical coatings on lenses, mirrors, and glass. These coatings can improve light transmission, create anti-reflective surfaces, or filter specific wavelengths of light.

Powering Electronics and Semiconductors

In the semiconductor industry, thin films are essential for creating conductive or insulating layers in integrated circuits. This process is also fundamental to manufacturing LED and OLED displays.

Advanced and Biomedical Applications

The technology enables the creation of ultra-small, high-performance structures. This includes components for batteries, solar cells, medical implants, and even systems for advanced drug delivery.

Understanding the Trade-offs

While powerful, thermal vapor deposition is not a universal solution. Understanding its limitations is key to using it effectively.

Material Compatibility

The process works best with materials, particularly pure elements like metals, that can be evaporated at a manageable temperature without decomposing or reacting. Complex alloys or compounds can be challenging to deposit with consistent composition.

Line-of-Sight Deposition

Since the vapor travels in straight lines, the process is considered "line-of-sight." This means it is excellent for coating flat surfaces but can struggle to uniformly coat complex, three-dimensional shapes with undercuts or hidden areas.

Film Adhesion and Density

Compared to higher-energy processes like sputtering, films from thermal deposition can sometimes have lower density and weaker adhesion to the substrate. However, for many applications, the quality is more than sufficient.

Making the Right Choice for Your Goal

Selecting a deposition method depends entirely on the material you are using and the properties you need in the final film.

- If your primary focus is cost-effective deposition of pure metals or simple compounds: Thermal vapor deposition is an excellent, reliable, and widely used choice.

- If your primary focus is achieving the highest possible film density or adhesion: You may need to explore alternative PVD methods like sputter deposition.

- If your primary focus is coating complex, non-flat geometries uniformly: A non-line-of-sight process may be required to ensure complete coverage.

Ultimately, thermal vapor deposition is a foundational technique that provides a simple, direct path from a solid material to a high-purity thin film.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Process Type | Physical Vapor Deposition (PVD) |

| Core Principle | Heating a solid material in a vacuum to create a vapor that condenses on a substrate. |

| Primary Use | Creating precise, uniform thin films for optical coatings, semiconductors, and advanced materials. |

| Ideal For | Cost-effective deposition of pure metals and simple compounds onto flat surfaces. |

| Key Limitation | Line-of-sight deposition; can struggle with complex 3D geometries. |

Ready to apply precise thin films to your substrates? The right equipment is critical for achieving high-purity, uniform coatings for your research or production. At KINTEK, we specialize in advanced lab equipment, including thermal deposition systems designed for reliability and performance. Our experts can help you select the perfect solution for your specific materials and application goals.

Let's discuss your project. Contact our team today to explore how our solutions can enhance your thin film processes.

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

People Also Ask

- What function does CVD equipment serve in rhodium-modified coatings? Achieve Deep Diffusion and Microstructural Precision

- What role does Chemical Vapor Deposition (CVD) equipment play in the preparation of C/C composites? Expert Analysis

- What is the floating catalyst method? A Guide to High-Yield CNT Production

- What are the methods of producing CNT? Scalable CVD vs. High-Purity Lab Techniques

- What are the main advantages of Chemical Vapor Deposition (CVD)? Achieve Precision Coating for Complex Geometries