At its core, sintering uses fine powder, immense pressure, and intense heat to transform loose material into a solid, unified mass. This process is not limited to a single substance; it is a versatile manufacturing technique that works with a wide range of materials, most notably powdered metals and ceramics, which are heated to a point just below their melting temperature to fuse them together.

Sintering is fundamentally a thermal process that bonds particles of a material together, creating a solid object without melting it. This allows for the creation of complex parts from materials like metal alloys and high-performance ceramics that can be difficult to shape using traditional methods.

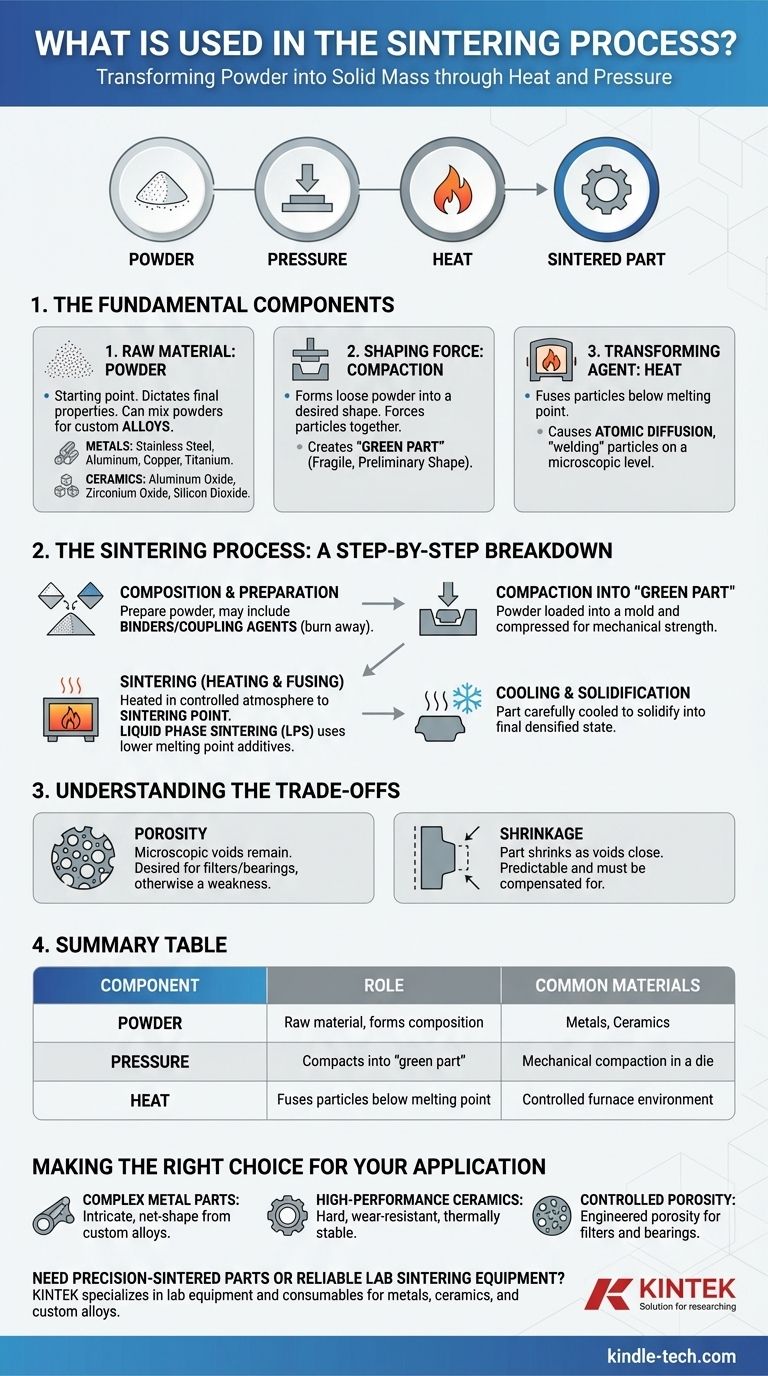

The Fundamental Components of Sintering

Sintering is best understood as a system with three primary components: the raw material, the shaping force, and the transforming agent.

The Raw Material: Powder

The starting point for any sintering process is a fine powder. The choice of powder dictates the final properties of the object.

Common materials include metals such as stainless steel, aluminum, copper, nickel, and titanium alloys. A key advantage of sintering is the ability to mix different metal powders to create custom alloys with unique characteristics.

The process is also widely used for ceramics, employing materials like aluminum oxide, zirconium oxide, silicon dioxide, and iron oxide to create hard, heat-resistant components.

The Shaping Force: Compaction

Before heating, the loose powder must be formed into the desired shape. This is achieved through mechanical compaction.

The powder is placed into a die or mold and subjected to high pressure. This process, often called cold or hot mold pressing, forces the particles into close contact, creating a fragile, preliminary shape known as a "green part."

The Transforming Agent: Heat

Heat is the critical agent that transforms the compressed powder into a dense, solid object.

The green part is heated in a controlled environment, such as a kiln or furnace, to a temperature below the material's melting point. This heat provides the energy for atoms to diffuse across the boundaries of the particles, effectively welding them together on a microscopic level.

The Sintering Process: A Step-by-Step Breakdown

While the components are simple, the process itself is a sequence of carefully controlled stages.

Stage 1: Composition and Preparation

This initial step involves preparing the raw powder. It may be a single material or a precise mixture of different powders to form an alloy.

Often, organic additives like binders or coupling agents are mixed in. These additives help the particles hold their shape during compaction and are designed to burn away cleanly during the heating stage.

Stage 2: Compaction into a 'Green Part'

The prepared powder mix is loaded into a mold and compressed. The goal is to create a green part with enough mechanical strength to be handled and moved to the furnace. The density of this green part is a critical factor for the final outcome.

Stage 3: Sintering (Heating and Fusing)

The green part is placed in a furnace with a controlled atmosphere (e.g., vacuum or inert gas to prevent oxidation). The temperature is raised to the sintering point, where the particles begin to fuse.

In some cases, Liquid Phase Sintering (LPS) is used. This involves adding a material with a lower melting point, which becomes liquid and accelerates the diffusion and bonding between the primary powder particles.

Stage 4: Cooling and Solidification

After being held at the sintering temperature for a specific duration, the part is carefully cooled. As it cools, it solidifies into its final, unified, and densified state.

Understanding the Trade-offs

Sintering is a powerful technique, but it comes with specific considerations that must be managed for a successful outcome.

Porosity

Because the material is not fully melted, microscopic voids, or porosity, can remain in the final part. In some applications, like filters or self-lubricating bearings, this is a desired feature. In others, it can be a structural weakness that must be minimized through precise control of pressure, temperature, and material composition.

Shrinkage

As the particles fuse and the voids between them close, the overall part will shrink. This dimensional change is predictable but must be accurately calculated and compensated for in the initial mold design to ensure the final part meets its required specifications.

Process Control

The quality of a sintered part depends on extremely tight process control. Factors like the atmosphere inside the furnace, the thickness of the material layer, heating and cooling rates, and machine speed must be monitored and regulated to ensure consistent results.

Making the Right Choice for Your Application

Understanding the goal of your component is key to leveraging the sintering process effectively.

- If your primary focus is complex metal parts: Sintering allows for the creation of intricate, net-shape components from custom alloys that would be costly or impossible to machine.

- If your primary focus is high-performance ceramics: This process is ideal for manufacturing hard, wear-resistant, and thermally stable parts from materials like zirconia or alumina for demanding applications.

- If your primary focus is components with controlled porosity: Sintering is one of the few manufacturing methods that allows you to engineer a specific level of porosity into a material, creating products like filters and bearings.

Ultimately, sintering provides a remarkable level of control over a material's final form and microstructure, directly from its powdered state.

Summary Table:

| Component | Role in Sintering Process | Common Materials |

|---|---|---|

| Powder | Raw material that forms the final part's composition | Metals (steel, aluminum, titanium), Ceramics (alumina, zirconia) |

| Pressure | Compacts powder into a 'green part' for handling | Applied via mechanical compaction in a die/mold |

| Heat | Fuses particles together below melting point | Controlled furnace environment (vacuum, inert gas) |

Need precision-sintered parts or reliable lab sintering equipment? KINTEK specializes in lab equipment and consumables, providing solutions for sintering metals, ceramics, and custom alloys. Our expertise ensures you get durable, complex components with controlled material properties. Contact our experts today to discuss your project requirements!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What thickness is magnetron sputtering for coating? Achieve Precise, Functional Thin Films

- What are the advantages of centrifugal extraction? Achieve High-Speed, High-Purity Separations

- What is the difference between smelting and sintering? A Guide to Metal Extraction vs. Powder Consolidation

- What is the softening temperature of quartz? Ensure Safe & Effective High-Temp Applications

- Can FTIR be used for quantitative analysis? Yes, Here's How to Measure Concentration Accurately

- What are the sources of biomass production? Exploring the Four Main Feedstock Categories

- Is sputtering done in vacuum? Discover How Vacuum Enables Superior Thin-Film Deposition

- Is pyrolysis of plastic harmful? The Truth About Toxic Byproducts and Environmental Risks