At its core, vacuum thin-film deposition is a family of processes used to apply an ultra-thin layer of material onto a surface, often atom by atom. These techniques all take place inside a vacuum chamber, which is crucial for controlling the purity and properties of the final coating. This allows for the creation of new surfaces with enhanced electrical, optical, or physical characteristics that the underlying material does not possess.

The central purpose of vacuum thin-film deposition is not just to coat a surface, but to fundamentally change its function. By precisely adding layers of material in a controlled, particle-free environment, we can transform an ordinary object into a high-performance component like a semiconductor, a specialized lens, or a durable medical implant.

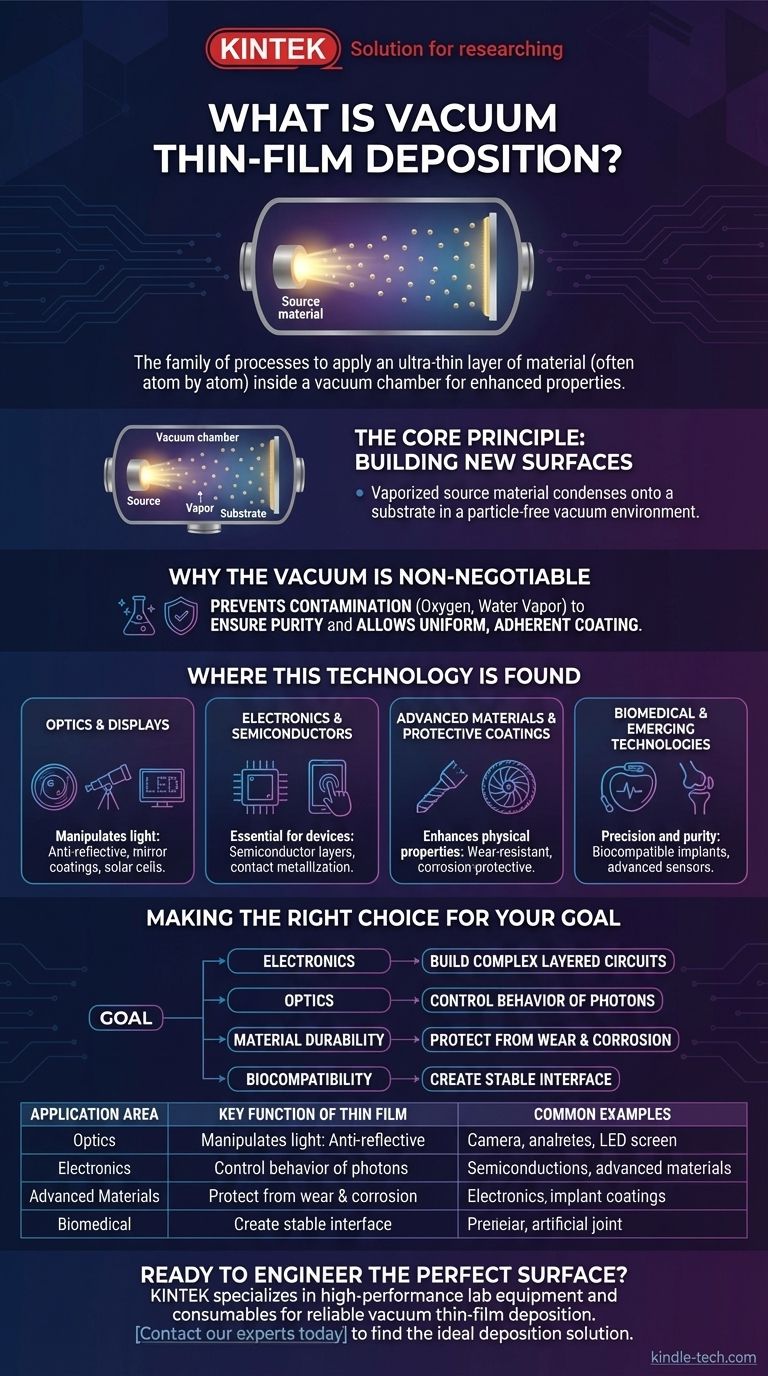

The Core Principle: Building New Surfaces

Vacuum deposition involves placing a base material (the substrate) into a vacuum chamber along with the material to be deposited (the source). The source material is then vaporized, travels through the vacuum, and condenses onto the substrate, forming a thin, uniform film.

Why the Vacuum is Non-Negotiable

The vacuum environment is the most critical element of the process. Removing air and other atmospheric gases prevents the vaporized coating material from reacting with contaminants like oxygen or water vapor.

This ensures the purity of the deposited film, which is essential for achieving the desired performance. It also allows the vaporized atoms to travel in a straight line to the substrate, resulting in a more uniform and adherent coating.

Where This Technology is Found

The ability to engineer surfaces at a microscopic level has made thin-film deposition a foundational technology across numerous industries. Its applications are diverse, but they can be grouped into several key areas.

Optics and Displays

One of the most common uses is to manipulate light. By controlling the thickness and composition of thin films, engineers can create coatings that improve the performance of optical devices.

This includes anti-reflective coatings on camera lenses and eyeglasses, mirror coatings on telescopes, and the layered materials that make up LED displays and solar cells.

Electronics and Semiconductors

Modern electronics would not exist without this technology. Thin-film deposition is essential for manufacturing semiconductor devices, where incredibly thin layers of conducting or insulating materials create the integrated circuits at the heart of every computer.

It is also used for contact metallization in electronic components and creating the transparent conductive layers on touch screens.

Advanced Materials and Protective Coatings

Beyond electronics, this process is used to enhance the physical properties of surfaces. It can create extremely hard, wear-resistant coatings for cutting tools and industrial equipment.

It is also used for corrosion-protective coatings in the aerospace industry and even for applying decorative coatings that provide both beauty and durability.

Biomedical and Emerging Technologies

The precision and purity of vacuum deposition make it ideal for medical applications. It is used to create biocompatible coatings on medical implants like pacemakers and artificial joints to ensure they are not rejected by the body.

Furthermore, it is a key manufacturing step for advanced sensors, next-generation batteries, and even components for quantum computers.

Making the Right Choice for Your Goal

Understanding the goal of the coating is the key to appreciating why this specific manufacturing process is chosen. The application dictates the material and precision required.

- If your primary focus is on electronics: You are using this process to build complex, layered circuits that manage the flow of electrons with extreme precision.

- If your primary focus is on optics: You are using thin films to control the behavior of photons, whether it's reducing reflection, creating mirrors, or absorbing light for energy.

- If your primary focus is on material durability: You are applying a hard, inert surface to protect a component from physical wear, chemical corrosion, or high temperatures.

- If your primary focus is on biocompatibility: You are creating a stable, non-reactive interface between a medical device and the human body.

Ultimately, vacuum thin-film deposition is the enabling technology that allows us to design the precise function of a material's surface, independent of its underlying structure.

Summary Table:

| Application Area | Key Function of Thin Film | Common Examples |

|---|---|---|

| Optics & Displays | Control light behavior | Anti-reflective coatings, LED displays, solar cells |

| Electronics & Semiconductors | Manage electrical flow | Integrated circuits, touch screens, contact metallization |

| Advanced Materials | Enhance surface durability | Wear-resistant tool coatings, corrosion protection |

| Biomedical Devices | Ensure biocompatibility | Coatings for pacemakers, artificial joints, sensors |

Ready to engineer the perfect surface for your application?

Whether you are developing advanced semiconductors, precision optics, durable industrial components, or biocompatible medical devices, the right thin-film solution is critical to your success.

KINTEK specializes in providing the high-performance lab equipment and consumables needed for reliable vacuum thin-film deposition. Our expertise supports laboratories in achieving the purity, uniformity, and adhesion required for breakthrough products.

Let's discuss how we can support your R&D and production goals. Contact our experts today to find the ideal deposition solution for your needs.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What are the drawbacks of PECVD? Understanding the Trade-offs of Low-Temperature Deposition

- What is the plasma CVD process? Achieve Low-Temperature Thin Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- What are the advantages of plasma enhanced CVD? Enable Low-Temperature, High-Quality Thin Film Deposition