While "var stainless" is not a standard metallurgical term, it almost certainly refers to vanadium stainless steel. This is a category of stainless steel where vanadium is intentionally added as an alloying element. The primary purpose of adding vanadium is to form exceptionally hard microscopic particles within the steel, dramatically increasing its wear resistance and ability to hold a sharp edge.

The core function of vanadium in stainless steel is to create extremely hard vanadium carbides. These microscopic structures give the steel superior edge retention and wear resistance, but often come at the cost of being more difficult to sharpen.

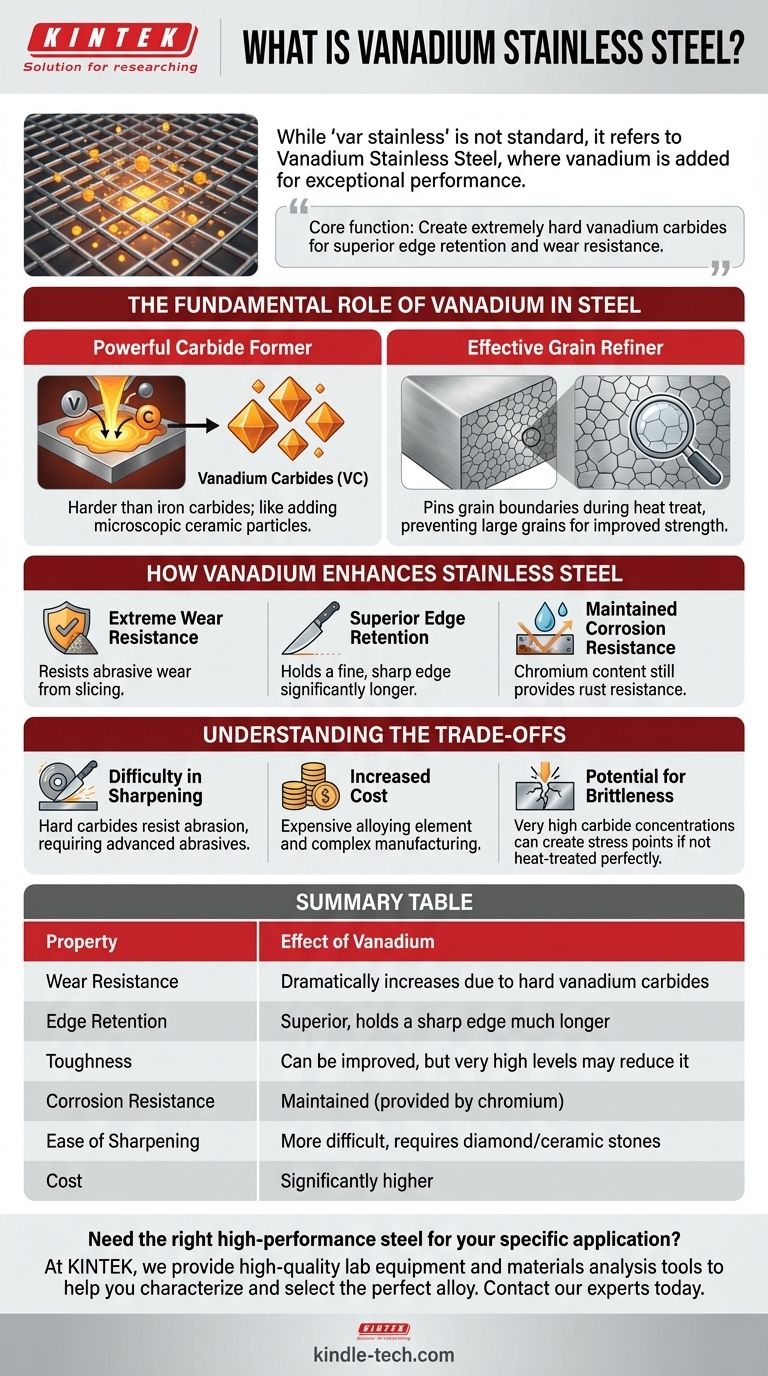

The Fundamental Role of Vanadium in Steel

To understand vanadium stainless steel, we must first understand what vanadium does to steel in general. Its influence is primarily based on two key mechanisms.

A Powerful Carbide Former

Steel's hardness is largely influenced by structures called carbides, which are compounds of carbon and a metallic element. While standard steel has iron carbides, vanadium is a much stronger carbide former.

When added to molten steel, vanadium combines with carbon to create vanadium carbides. These particles are significantly harder than the iron carbides found in simpler steels.

Think of it like adding microscopic ceramic particles into the steel matrix. This is the primary reason for the dramatic increase in wear resistance.

An Effective Grain Refiner

During the heat-treating process, vanadium helps to pin the boundaries of the steel's crystals, or "grains." This prevents the grains from growing too large.

A finer, more uniform grain structure is highly desirable because it directly improves the steel's toughness and strength. This allows for a blade or tool that is both very hard and resistant to chipping.

How Vanadium Enhances Stainless Steel

When these properties are introduced to a stainless steel base (which already has chromium for corrosion resistance), the result is a high-performance material with specific advantages.

Extreme Wear Resistance

The hardness of the vanadium carbides provides exceptional resistance to abrasive wear. For a knife, this means it will take much longer for the cutting edge to dull from slicing through materials.

Superior Edge Retention

Wear resistance directly translates to edge retention. A steel that can resist abrasion will hold a fine, sharp edge for a significantly longer period of use compared to steels without strong carbide formers. This is the most sought-after benefit of high-vanadium steels.

Maintained Corrosion Resistance

The addition of vanadium does not compromise the "stainless" properties of the steel. The chromium content is still responsible for rust and corrosion resistance, and vanadium works alongside it to enhance other performance metrics.

Understanding the Trade-offs

No material is perfect, and the benefits of vanadium come with practical compromises that are critical to understand.

Difficulty in Sharpening

The very same hard carbides that provide excellent edge retention also resist being abraded by sharpening stones. High-vanadium steels can be notoriously difficult and time-consuming to sharpen.

Effective sharpening often requires more advanced abrasives, such as diamond or ceramic stones, as traditional stones may struggle to cut the hard vanadium carbides efficiently.

Increased Cost

Vanadium is a relatively expensive alloying element. This, combined with the more complex manufacturing and heat treatment processes required, results in a significantly higher cost for the final product.

Potential for Brittleness

While vanadium is a grain refiner that improves toughness, very high concentrations of large carbides can create stress points within the steel if not heat-treated perfectly. This can make the steel more prone to chipping under impact, a property known as lower toughness.

Making the Right Choice for Your Goal

Ultimately, whether a high-vanadium stainless steel is "better" depends entirely on your specific needs and priorities.

- If your primary focus is maximum edge retention for slicing tasks: Choose a high-vanadium steel like CPM-S30V, CPM-S90V, or M390, but be prepared for the sharpening challenge.

- If your primary focus is a balance of good edge retention and toughness: Look for steels with a more moderate vanadium content, such as CPM-S35VN or VG-10, which offer a great all-around compromise.

- If your primary focus is ease of sharpening, high toughness, and good corrosion resistance: Select a stainless steel with little or no vanadium, like Sandvik 14C28N, which is much more forgiving for general-purpose use.

Understanding the role of vanadium allows you to select a steel based on its precise performance characteristics, not just its name.

Summary Table:

| Property | Effect of Vanadium |

|---|---|

| Wear Resistance | Dramatically increases due to hard vanadium carbides |

| Edge Retention | Superior, holds a sharp edge much longer |

| Toughness | Can be improved via grain refinement, but very high levels may reduce it |

| Corrosion Resistance | Maintained (provided by chromium content) |

| Ease of Sharpening | More difficult, requires diamond or ceramic stones |

| Cost | Significantly higher due to expensive alloy and complex processing |

Need the right high-performance steel for your specific application?

At KINTEK, we specialize in providing high-quality lab equipment and consumables, including materials analysis tools that can help you characterize and select the perfect alloy for your needs. Whether you're developing cutting tools, components requiring extreme wear resistance, or any other laboratory application, our expertise can guide you to the optimal solution.

Contact our experts today to discuss how we can support your laboratory's material science challenges.

Visual Guide

Related Products

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

- Stainless Steel Quick Release Vacuum Chain Three-Section Clamp

- Silicon Carbide (SIC) Ceramic Sheet Wear-Resistant Engineering Advanced Fine Ceramics

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

- Rubber Vulcanizer Vulcanizing Machine Plate Vulcanizing Press for Lab

People Also Ask

- What is the difference between PPF and coating? Armor vs. Slick Shell for Your Car

- What is the impact factor of powder metallurgy progress? A 2022 Analysis & Context

- What are the advantages of using PTFE molds for epoxy resin flame retardant samples? Ensure High-Purity Material Testing

- What is the function of PTFE reaction kettle bodies in micro-CSTR systems? Enhance Chemical Stability & Flow

- Why are PTFE laboratory consumables required when testing stainless steel against organic acids? Ensure Data Integrity