In the world of biomedical materials, zirconia is a high-performance ceramic used to create incredibly durable and biocompatible medical and dental implants. It is chemically zirconium dioxide (ZrO₂), a white crystalline oxide that combines exceptional strength, high fracture toughness, and excellent wear resistance, making it an ideal substitute for metal alloys in many applications.

Zirconia isn't just a strong material; it's a uniquely tough ceramic that actively resists cracking. This "transformation toughening" mechanism gives it metal-like durability while retaining the inert, biocompatible properties essential for long-term use inside the human body.

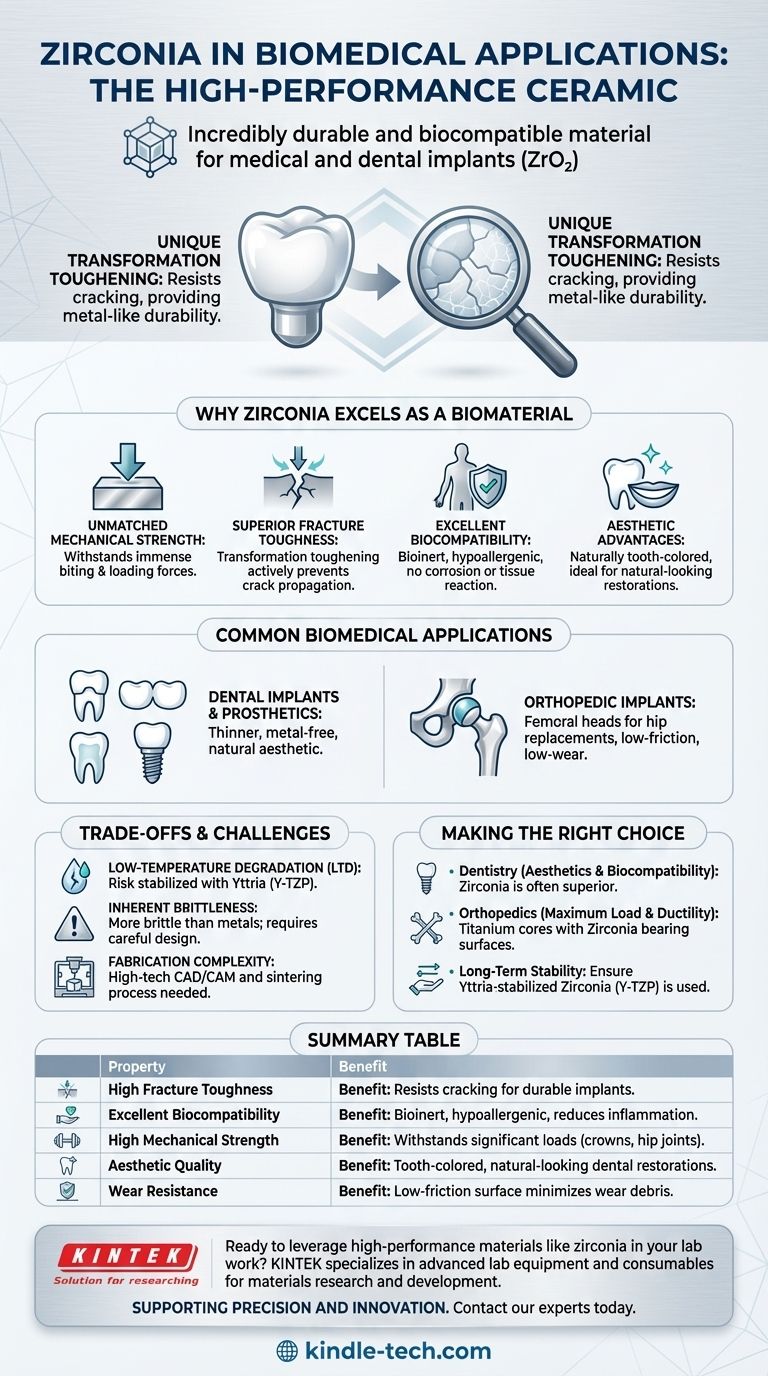

Why Zirconia Excels as a Biomaterial

The suitability of a material for use in the body depends on a specific combination of properties. Zirconia meets these demands through a unique set of characteristics that set it apart from both metals and other ceramics.

### Unmatched Mechanical Strength

Zirconia exhibits very high compressive strength, meaning it can withstand immense biting or loading forces without breaking. This makes it a premier material for dental crowns and the load-bearing surfaces of joint replacements.

### Superior Fracture Toughness

This is zirconia's most critical feature. Most ceramics are brittle—a small crack can spread rapidly and cause failure. Zirconia is engineered with a property called transformation toughening.

When a micro-crack starts to form under stress, the crystal structure of the zirconia around the crack tip instantly changes to a different phase. This transformation causes a localized volume expansion that effectively squeezes the crack shut, halting its progression and making the material remarkably resistant to fracture.

### Excellent Biocompatibility

Zirconia is bioinert, meaning it does not corrode, leach metallic ions, or cause inflammatory or allergic reactions in the body. This is a significant advantage over certain metal alloys, which can cause sensitivity or tissue discoloration in some patients.

### Aesthetic Advantages

For dental applications, aesthetics are paramount. Zirconia is naturally tooth-colored and can be milled and glazed to match the shade and translucency of a patient's natural teeth. This allows for strong, full-ceramic restorations without the dark metal line at the gum that is common with traditional porcelain-fused-to-metal crowns.

Common Biomedical Applications

Zirconia's unique properties have made it a material of choice in two primary fields: dentistry and orthopedics.

### Dental Implants and Prosthetics

Zirconia is widely used for crowns, bridges, and implant abutments. Its strength allows for thinner restorations that preserve more of the natural tooth structure. Because it's metal-free, it provides a more natural look and is the ideal solution for patients with metal allergies.

### Orthopedic Implants

In orthopedics, zirconia is primarily used for the femoral heads of hip replacements. Its extremely hard and smooth surface creates a low-friction, low-wear bearing when paired with a polyethylene socket. This reduces the generation of wear debris, which is a primary cause of implant loosening and failure over time.

Understanding the Trade-offs and Challenges

No material is perfect. While zirconia offers profound advantages, it's essential to understand its limitations.

### The Risk of Low-Temperature Degradation (LTD)

Over many years in the warm, wet environment of the body, some zirconia formulations can undergo a slow phase transformation that can lead to surface micro-cracking and a reduction in strength. Modern biomedical-grade zirconia is stabilized with elements like yttria (Y-TZP) to vastly improve its long-term stability and mitigate this risk.

### Inherent Brittleness (Compared to Metals)

Although it is exceptionally tough for a ceramic, zirconia is still more brittle than metals like titanium. It does not bend or deform before failing; if its fracture toughness is exceeded, it will break. This factor heavily influences implant design and clinical handling.

### Fabrication Complexity

Processing zirconia is a highly technical process. In dentistry, it is typically milled from a solid block in an oversized, soft state using CAD/CAM technology and then sintered in a furnace at high temperatures to achieve its final density and strength. This complexity can influence the final cost.

Making the Right Choice for Your Goal

The choice between zirconia, metals like titanium, or other ceramics depends entirely on the specific clinical demands of the application.

- If your primary focus is aesthetics and biocompatibility in dentistry: Zirconia is often the superior choice for crowns and bridges, offering strength without the risk of metal allergies or a visible metal margin.

- If your primary focus is maximum load-bearing and ductility in orthopedics: Titanium alloys remain the standard for the core structural components of implants, while zirconia excels as the wear-resistant bearing surface (e.g., the femoral head).

- If your primary focus is ensuring long-term implant stability: You must confirm the use of a modern, yttria-stabilized zirconia (Y-TZP) that has been processed correctly to minimize the risk of low-temperature degradation.

Ultimately, zirconia's value lies in its unique ability to combine the strength of a metal with the inertness and appearance of a ceramic, making it a cornerstone of modern restorative medicine.

Summary Table:

| Property | Benefit for Biomedical Use |

|---|---|

| High Fracture Toughness | Resists cracking under stress for durable implants |

| Excellent Biocompatibility | Bioinert, hypoallergenic, reduces risk of inflammation |

| High Mechanical Strength | Withstands significant loads (e.g., in dental crowns, hip replacements) |

| Aesthetic Quality | Tooth-colored, ideal for natural-looking dental restorations |

| Wear Resistance | Low-friction surface minimizes wear debris in joint replacements |

Ready to leverage high-performance materials like zirconia in your lab work? KINTEK specializes in providing the advanced lab equipment and consumables needed for materials research and development. Whether you're developing next-generation biomedical implants or testing material properties, our solutions support precision and innovation. Contact our experts today to discuss how we can equip your laboratory for success.

Visual Guide

Related Products

- Custom-Made Alumina Zirconia Special-Shaped Ceramic Plates for Engineering Advanced Fine Ceramics Processing

- Precision Machined Yttrium Stabilized Zirconia Ceramic Rod for Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Ceramics Head Tweezers with Pointed Elbow Zirconia Ceramic Tip

- Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

- Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

People Also Ask

- What is the thermal stability of SiC? Withstand Extreme Heat Up to 2700°C

- Why is porcelain heat resistant? The Science of High-Temperature Resilience Explained

- What are the methods of high temperature ceramic? Master the 3-Stage Process for Durable Components

- What are the roles of sintering additives? Master the Process for Superior Material Performance

- What temperature do you fire alumina? Achieve Optimal Density and Strength

- What are the classification of ceramic powder? A Guide to Selecting the Right Material for Your Application

- What is a ceramic tube? A Guide to Extreme Environment Performance

- What are the factors affecting ceramic structure? From Atomic Charge to Final Properties