To be effective, plastic pyrolysis can process a wide range of materials that are difficult to handle with traditional recycling. The most suitable feedstocks are post-consumer plastics, mixed plastics from municipal solid waste, multi-layer packaging, and materials rejected by mechanical recycling facilities. These sources primarily consist of common polymers that break down efficiently into valuable oils and gases.

The core principle is simple: plastics made primarily of carbon and hydrogen, like Polyethylene (PE) and Polypropylene (PP), are ideal for pyrolysis. Plastics containing other elements, such as chlorine (in PVC) or oxygen (in PET), introduce significant technical challenges that must be managed.

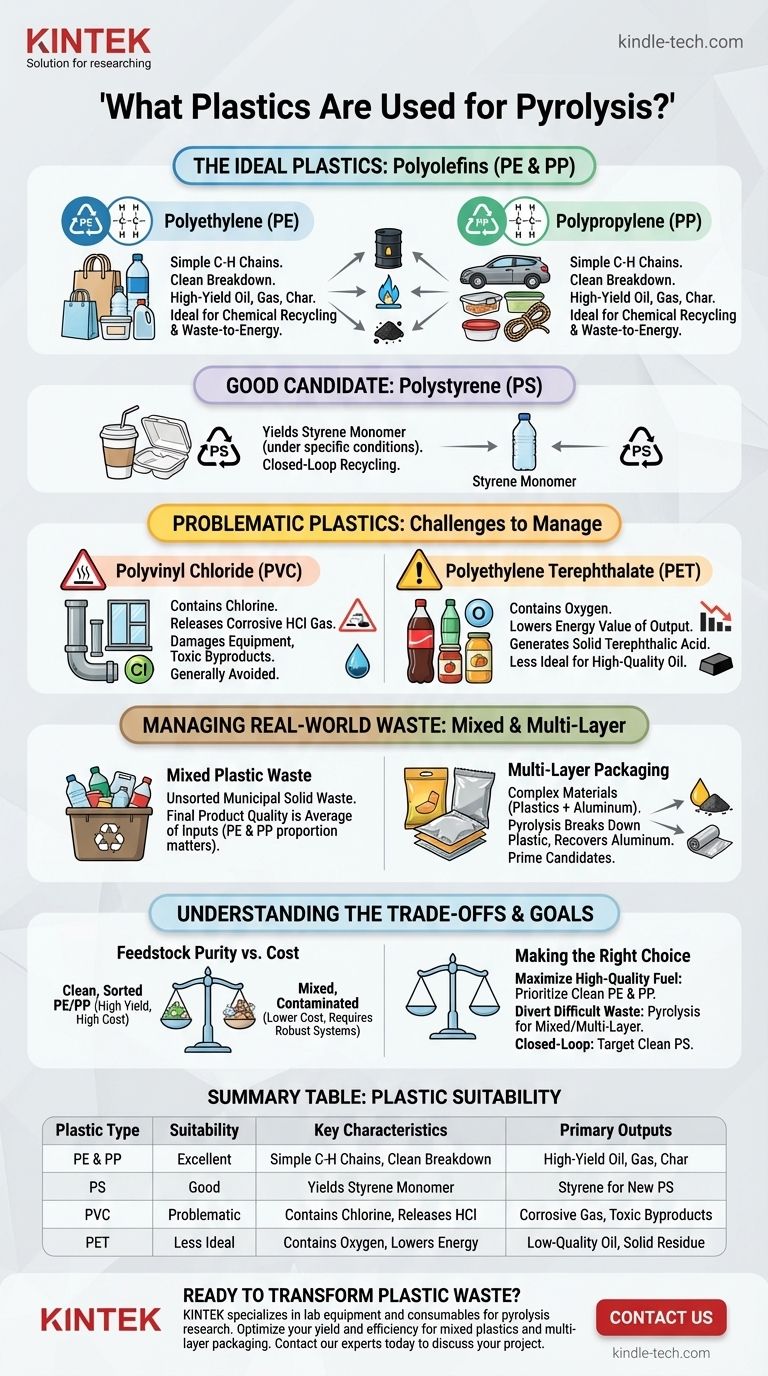

The Ideal Plastics for Pyrolysis

The effectiveness of pyrolysis is determined by the chemical makeup of the plastic polymer being processed. The goal is to break down long polymer chains into smaller, valuable hydrocarbon molecules.

Polyolefins (PE and PP)

Polyethylene (PE) and Polypropylene (PP) are the best candidates for pyrolysis. These plastics are used in everything from shopping bags and food containers to car parts.

Their chemical structure consists of simple, long chains of carbon and hydrogen. When heated in the absence of oxygen, they break down cleanly into a high-yield mix of synthetic oil (pyrolysis oil), gas, and char.

This makes them highly desirable for chemical recycling and waste-to-energy applications, as the outputs can be refined into new fuels or chemical feedstocks.

Polystyrene (PS)

Polystyrene (PS), found in items like disposable cups and foam packaging, is also a good candidate.

It yields a high percentage of styrene monomer when pyrolyzed under specific conditions. This monomer can then be used to produce new polystyrene, creating a closed-loop recycling path.

Problematic Plastics and Their Challenges

While many plastics can technically be pyrolyzed, some create significant operational and environmental problems due to their atomic composition.

Polyvinyl Chloride (PVC)

PVC is one of the most problematic plastics for pyrolysis. Its structure contains chlorine atoms.

During pyrolysis, this chlorine is released primarily as hydrochloric acid (HCl) gas. This gas is highly corrosive, damaging equipment, and it can also form toxic dioxins if not properly controlled.

While systems can be designed with de-chlorination steps to handle small amounts of PVC contamination, it is generally avoided as a primary feedstock.

Polyethylene Terephthalate (PET)

PET, commonly used for soda bottles and food jars, is less than ideal for producing high-quality pyrolysis oil.

The polymer chain of PET contains a significant amount of oxygen. During pyrolysis, this oxygen ends up in the resulting oil and gas, lowering their energy content and making them less valuable as fuel. The process also generates solid terephthalic acid.

Managing Real-World Waste Streams

In practice, plastic waste is never perfectly sorted. Pyrolysis is often valued for its ability to handle the mixed and contaminated streams that mechanical recycling cannot.

Mixed Plastic Waste

Pyrolysis can effectively process unsorted municipal solid waste plastics. The final product's quality will be an average of its inputs, with the high proportion of PE and PP typically ensuring a usable oil.

Multi-Layer Packaging

Complex materials like food pouches and flexible packaging, which combine layers of different plastics and aluminum, are prime candidates for pyrolysis.

Mechanical recycling cannot separate these bonded layers. Pyrolysis, however, can break down the plastic components into oil and gas, leaving materials like aluminum foil behind as a solid that can be recovered.

Understanding the Trade-offs

Choosing to use pyrolysis involves accepting a series of technical and economic trade-offs based on the feedstock you intend to process.

Feedstock Purity vs. Cost

A clean, sorted stream of PE and PP will produce the highest quality and yield of pyrolysis oil. However, acquiring this pure feedstock can be expensive.

Using cheaper, mixed, and contaminated waste streams reduces input cost but requires more sophisticated and robust pyrolysis systems. The resulting oil may also need more extensive upgrading before it can be used.

The Impact of Contaminants

Non-plastic contaminants like dirt, moisture, paper, and organic waste can negatively impact the process. Moisture consumes a great deal of energy to vaporize, and organic waste can alter the chemical composition of the final products.

Effective pre-treatment, such as shredding, washing, and drying, is often a critical step to ensure an efficient and stable pyrolysis operation.

Making the Right Choice for Your Goal

The suitability of a plastic feedstock depends entirely on your primary objective.

- If your primary focus is maximizing high-quality fuel yield: Prioritize clean and sorted streams of Polyethylene (PE) and Polypropylene (PP).

- If your primary focus is diverting difficult waste from landfills: Pyrolysis is an excellent solution for mixed plastics, multi-layer packaging, and materials rejected by traditional recycling facilities.

- If your primary focus is closed-loop chemical recycling: Target clean streams of Polystyrene (PS) to recover high-value styrene monomer.

Ultimately, pyrolysis offers a powerful and flexible technology for converting a wide range of plastic wastes into valuable resources, especially those that have no other viable recycling path.

Summary Table:

| Plastic Type | Suitability for Pyrolysis | Key Characteristics | Primary Outputs |

|---|---|---|---|

| Polyethylene (PE) & Polypropylene (PP) | Excellent | Simple carbon-hydrogen chains; clean breakdown | High-yield pyrolysis oil, gas, char |

| Polystyrene (PS) | Good | Yields styrene monomer under specific conditions | Styrene for new PS (closed-loop) |

| Polyvinyl Chloride (PVC) | Problematic | Contains chlorine; releases corrosive HCl gas | Damaged equipment, toxic byproducts |

| Polyethylene Terephthalate (PET) | Less Ideal | Contains oxygen; lowers energy value of output | Low-quality oil, solid terephthalic acid |

Ready to transform your plastic waste into valuable resources? KINTEK specializes in lab equipment and consumables for pyrolysis research and development. Whether you're processing mixed plastics, multi-layer packaging, or aiming for closed-loop recycling, our solutions help you optimize yield and efficiency. Contact our experts today to discuss how we can support your laboratory's plastic pyrolysis projects!

Visual Guide

Related Products

- Customizable Laboratory High Temperature High Pressure Reactors for Diverse Scientific Applications

- Small Lab Rubber Calendering Machine

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Laboratory High Throughput Tissue Grinding Mill Grinder

People Also Ask

- What is refractory in rotary kiln? A Guide to Protecting Your Kiln and Maximizing Efficiency

- What are the factors affecting plastic pyrolysis? Optimize Yield and Quality from Waste Plastic

- What are the uses of pyrolysis products? Unlock Value from Bio-Oil, Biochar, and Syngas

- What is the rotary kiln process? A Guide to Efficient High-Temperature Material Processing

- What is the primary function of an industrial rotary tube furnace? Master Tungsten Powder Hydrogen Reduction

- What are the steps of biomass pyrolysis? Turn Waste into Biochar, Bio-Oil & Biogas

- What is pyrolysis and why is it important in the combustion process? Unlock the Hidden First Stage of Fire

- What are the applications of pyrolysis? Converting Waste into Valuable Fuels and Chemicals