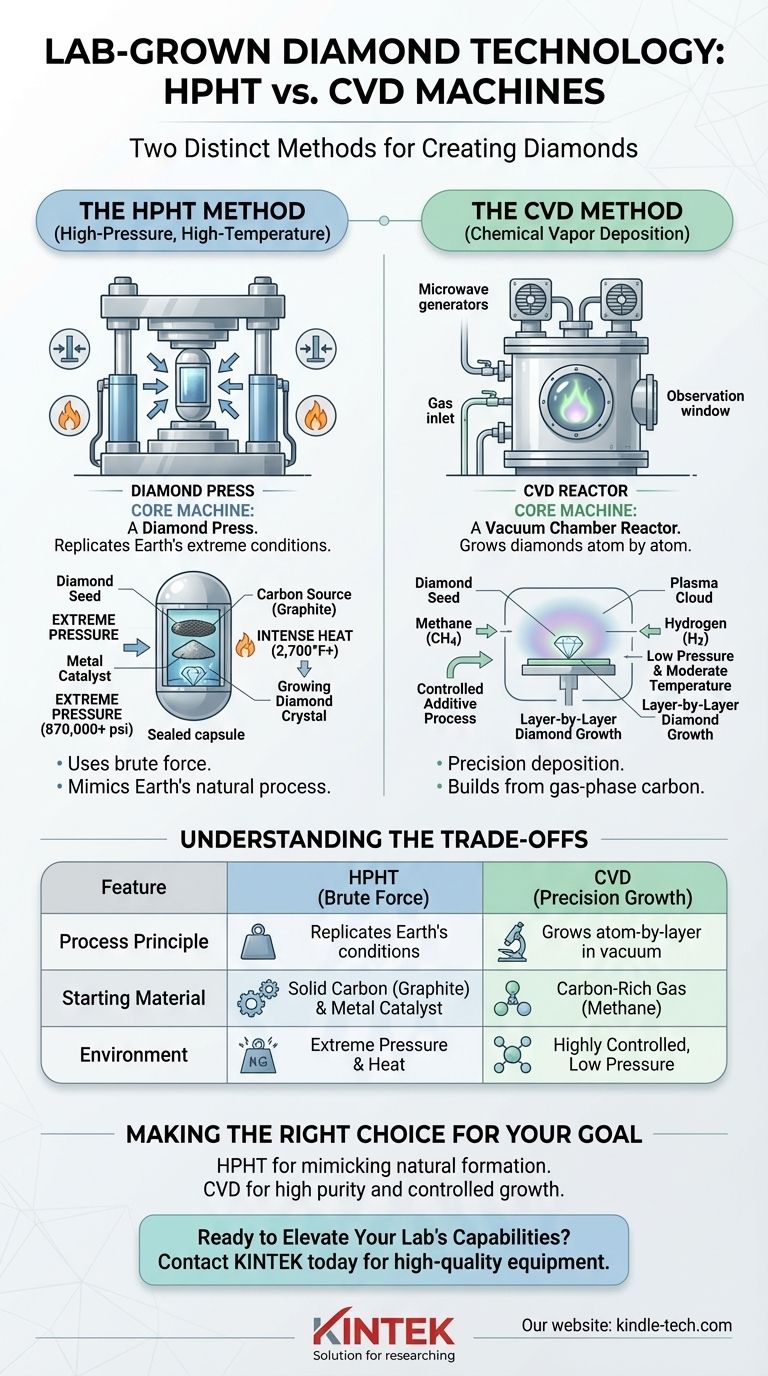

To be clear, there is no single machine for making diamonds. Instead, two distinct technologies are used, each centered around a different type of apparatus: a High-Pressure, High-Temperature (HPHT) press, and a Chemical Vapor Deposition (CVD) reactor. The HPHT method crushes carbon under immense force to mimic the Earth's natural process, while the CVD method "grows" a diamond atom by atom from a gas.

The core distinction is not just the machine, but the fundamental principle. One method uses brute force (HPHT) to replicate the conditions deep within the Earth, while the other uses a highly controlled, additive process (CVD) to build a diamond from a chemical vapor.

The HPHT Method: Replicating Earth's Force

The High-Pressure, High-Temperature method is the original technique for creating lab-grown diamonds. It is a direct attempt to recreate the conditions that form diamonds naturally in the Earth's mantle.

The Core Machine: A Diamond Press

The central piece of equipment is a massive mechanical press capable of generating enormous pressure and high temperatures simultaneously. These machines are engineered to apply force from multiple directions to a small, sealed capsule.

The pressures involved are extreme, often exceeding 870,000 pounds per square inch (psi), with temperatures reaching over 2,700°F (1,500°C).

The Process Inside the Press

A small diamond seed is placed in a capsule with a source of pure carbon, such as graphite. A metal catalyst is also included, which helps dissolve the carbon.

Under the intense heat and pressure from the press, the metal catalyst melts and dissolves the carbon source. This molten solution allows the carbon atoms to move and recrystallize onto the cooler diamond seed, slowly forming a larger, pure diamond crystal.

The CVD Method: Building Diamonds Atom by Atom

Chemical Vapor Deposition is a more recent technology that takes a fundamentally different approach. It doesn't rely on brute force but on a meticulous, additive process that builds the diamond layer by layer.

The Core Machine: A Vacuum Chamber Reactor

The machine for this process is a sealed vacuum chamber, often called a CVD reactor. This chamber is designed to maintain extremely low pressures and allow for the precise introduction of specific gases.

Inside the chamber, an energy source—typically microwaves—is used to heat the gases into a plasma state.

The Process Inside the Reactor

A thin slice of a diamond, known as a seed crystal, is placed inside the chamber. All other air is vacuumed out to prevent contamination.

Carbon-rich gases, like methane, are introduced into the chamber along with hydrogen. The energy source breaks these gas molecules apart, creating a plasma cloud of carbon and hydrogen atoms.

The free carbon atoms are then drawn down to the cooler diamond seed, depositing on its surface and replicating its crystal structure. This builds up the diamond, one atomic layer at a time.

Understanding the Trade-offs

Choosing between HPHT and CVD is not about which is "better," but about understanding their different processes and outcomes.

Pressure vs. Precision

HPHT is a brute-force method defined by immense pressure. It forces carbon into a diamond structure in a process that is powerful but less granularly controlled.

CVD is a deposition method defined by precision. It operates at much lower pressures and moderate temperatures, allowing for more direct control over the growth environment.

Growth Materials and Environment

The HPHT process starts with a solid carbon source (graphite) and requires a metal catalyst to facilitate the transformation.

The CVD process starts with a gas-phase carbon source (methane) and operates in a vacuum, which helps produce diamonds of very high purity.

Making the Right Choice for Your Goal

The technology used depends entirely on the desired outcome, as each method has its own distinct advantages.

- If your primary focus is to mimic the Earth's formation process directly: The HPHT press is the machine that uses the same principles of extreme pressure and heat.

- If your primary focus is to grow a high-purity diamond in a highly controlled, additive manner: The CVD reactor is the technology that builds the crystal atom by atom from a gas.

Ultimately, both machines are sophisticated tools that have mastered the elemental process of turning simple carbon into a perfect diamond.

Summary Table:

| Method | Core Machine | Process Principle | Starting Material |

|---|---|---|---|

| HPHT | High-Pressure, High-Temperature Press | Replicates Earth's natural conditions with extreme force | Solid Carbon (Graphite) & Metal Catalyst |

| CVD | Chemical Vapor Deposition (CVD) Reactor | Grows diamond atom-by-layer in a vacuum chamber | Carbon-Rich Gas (Methane) |

Ready to Elevate Your Lab's Capabilities?

Choosing the right equipment is critical for successful lab-grown diamond research or production. At KINTEK, we specialize in providing high-quality laboratory equipment and consumables tailored to your specific needs.

Whether you are exploring HPHT or CVD methodologies, our experts can help you select the right tools to achieve precision, purity, and efficiency in your work.

Contact us today to discuss how our solutions can support your laboratory's innovation and growth. Get in touch via our contact form – let's build the future of materials science together.

Visual Guide

Related Products

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- Double Plate Heating Press Mold for Lab

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

People Also Ask

- How does pressure affect deposition? Mastering the Key to High-Quality Film Growth

- Why is thin film deposition important? Unlock New Surface Properties for Your Materials

- Why are CVD or sintering furnaces necessary for SiC cladding? Unlock the Future of Accident Tolerant Fuel

- What is physical Vapour deposition method of nanomaterials? A Guide to High-Performance Thin Films

- What is the sputtering technique of magnetron? A Guide to High-Quality Thin Film Deposition

- What is a sputtering target in thin film? The Core Source for High-Quality Coatings

- What is the primary function of CVD equipment for TCO films? Achieve Precision Control for High-Quality Coatings

- What are the advantages of chemical deposition? Achieve Superior, Conformal Coatings for Complex Parts