In short, furnace tubes are most commonly made from heat-resistant metal alloys, quartz, or high-purity ceramics like alumina. The specific material is carefully chosen based on the furnace's maximum operating temperature, the chemical atmosphere required, and the type of material being processed. This selection ensures the tube can withstand extreme conditions without cracking, melting, or contaminating the sample.

The choice of a furnace tube material is not a matter of simple preference; it is a critical engineering decision. The right material must balance extreme temperature resistance, chemical inertness, and mechanical durability against the specific demands of the thermal process.

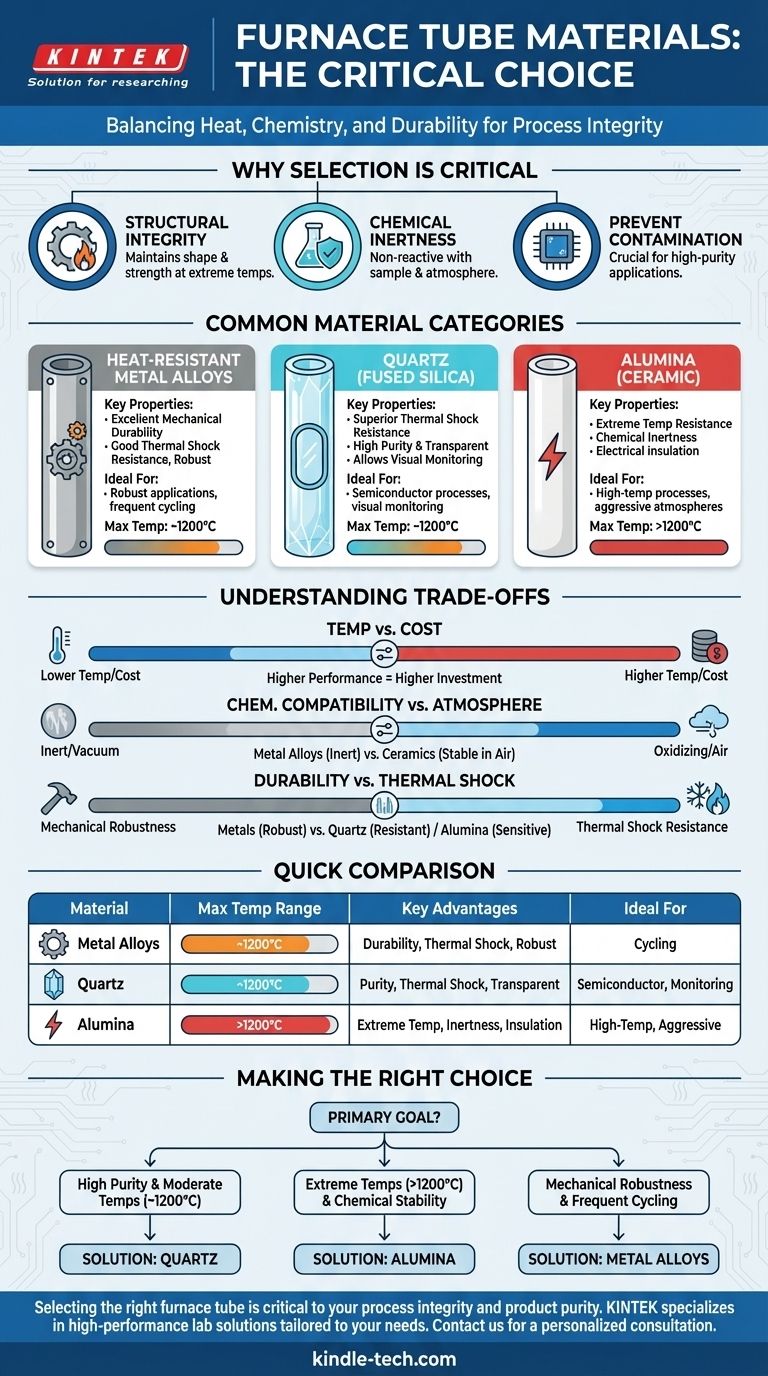

Why Material Selection is So Critical

The furnace tube is the heart of the system. It creates the controlled environment where the heating process, or reaction, takes place.

The Core Functions of a Furnace Tube

A furnace tube must maintain its structural integrity at extremely high temperatures. Any weakness or failure can ruin an experiment or production run.

It must also be chemically inert in relation to both the sample material inside it and the furnace atmosphere (e.g., air, vacuum, or an inert gas like argon).

Finally, the tube must prevent contamination. This is especially crucial in high-purity applications like semiconductor manufacturing, where even trace elements from the tube can compromise the final product.

Common Furnace Tube Materials and Their Properties

Different applications demand different materials. The three most common categories each offer a unique set of advantages.

Heat-Resistant Metal Alloys

Materials like stainless steel and other advanced heat-resistant alloys are used for their excellent mechanical properties.

They offer superior durability and are less prone to cracking from physical shock compared to ceramics. They also handle rapid temperature changes (thermal shock) very well. However, they typically have a lower maximum operating temperature than ceramics and can react with certain process materials or atmospheres.

Quartz (Fused Silica)

Quartz is a type of high-purity glass valued for its exceptional thermal shock resistance. It can withstand rapid heating and cooling cycles without fracturing.

Its high purity makes it ideal for processes where contamination is a major concern, such as in the semiconductor industry. Its transparency is also a unique benefit, allowing for visual monitoring of the process. Its primary limitation is a lower maximum service temperature compared to alumina.

Alumina (Aluminum Oxide)

For the highest temperatures, alumina is a go-to ceramic material. High-purity alumina tubes can operate consistently at temperatures where metals would fail.

Alumina offers excellent chemical resistance and is a superb electrical insulator. This makes it suitable for a wide range of aggressive chemical environments and high-heat applications.

Understanding the Trade-offs

Choosing a furnace tube material involves balancing competing priorities. There is no single "best" material, only the most appropriate one for the job.

Temperature vs. Cost

Generally, the higher the required operating temperature, the more specialized and expensive the tube material becomes. A high-purity alumina tube capable of reaching 1700°C will cost significantly more than a quartz tube rated for 1200°C.

Chemical Compatibility vs. Atmosphere

The furnace atmosphere is a deciding factor. A metal alloy tube might perform well in a vacuum or inert gas but could oxidize and degrade quickly if used in an air atmosphere at high temperatures. In contrast, a ceramic tube like alumina is stable in air at very high temperatures.

Mechanical Durability vs. Thermal Shock

Metal alloys are robust and ductile, making them resistant to mechanical breakage. Ceramics are very hard but can be brittle. While quartz has excellent thermal shock resistance, other ceramics like alumina can be more sensitive and may require slower, more controlled heating and cooling ramps to prevent cracking.

Making the Right Choice for Your Application

Your final decision should be guided by the primary goal of your thermal process.

- If your primary focus is high purity at moderate temperatures (up to ~1200°C): Quartz is often the best choice due to its inertness and excellent thermal shock resistance.

- If your primary focus is extreme temperatures (above 1200°C) and chemical stability: High-purity alumina or another advanced ceramic is the necessary solution.

- If your primary focus is mechanical robustness and frequent thermal cycling: A heat-resistant metal alloy is a strong contender, provided its temperature and chemical limitations are respected.

Selecting the correct furnace tube material is a strategic decision that directly ensures the integrity, success, and reliability of your high-temperature process.

Summary Table:

| Material | Max Temp Range | Key Advantages | Ideal For |

|---|---|---|---|

| Metal Alloys | Up to ~1200°C | Excellent mechanical durability, good thermal shock resistance | Robust applications, frequent cycling |

| Quartz | Up to ~1200°C | High purity, superior thermal shock resistance, transparent | Semiconductor processes, visual monitoring |

| Alumina | >1200°C | Extreme temperature resistance, chemical inertness, electrical insulation | High-temperature processes, aggressive atmospheres |

Selecting the right furnace tube is critical to your process integrity and product purity. At KINTEK, we specialize in providing high-performance lab equipment and consumables, including furnace tubes tailored to your specific temperature, atmosphere, and contamination-control requirements. Our experts can help you navigate the trade-offs between materials like quartz, alumina, and metal alloys to ensure your thermal processes are reliable and successful. Contact us today to discuss your application and get a recommendation that protects your samples and your budget. Reach out via our contact form for a personalized consultation!

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory High Pressure Vacuum Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- High Temperature Alumina (Al2O3) Furnace Tube for Engineering Advanced Fine Ceramics

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What is a tubular furnace used for? Precision Heating for Material Synthesis & Analysis

- What materials are used for the tubes in tube furnaces? A Guide to Selecting the Right Tube for Your Process

- How to clean a tube furnace? A Step-by-Step Guide for Safe and Effective Maintenance

- Why use a tube furnace? Achieve Superior Temperature Uniformity and Atmosphere Control

- How does a quartz tube vacuum furnace contribute to the crystallization process of Ag-doped Li-argyrodite electrolytes?