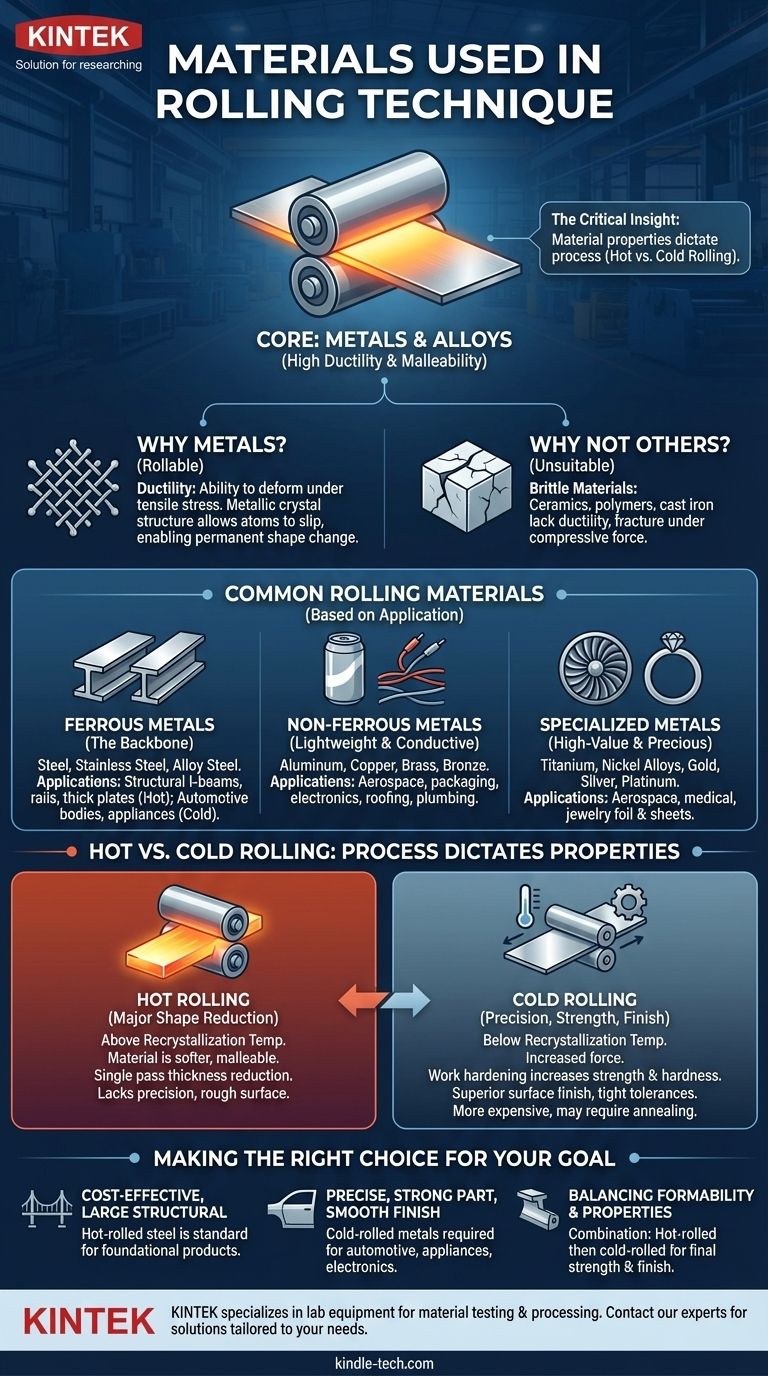

At its core, the rolling technique is almost exclusively used for metals and their alloys. The process is designed to shape materials that possess high ductility and malleability, with steel, aluminum, and copper being the most common examples processed into plates, sheets, and structural shapes.

The critical insight is not just which materials are rolled, but how a material's properties dictate the chosen process—either hot rolling for massive shape changes or cold rolling for achieving precision, strength, and a fine surface finish.

The Defining Characteristic: Why Metals Dominate Rolling

Rolling is a metal forming process where stock is passed through one or more pairs of rolls to reduce its thickness and make it uniform. The material's ability to undergo this process is determined by its physical properties.

What Makes a Material "Rollable"?

The single most important property for rolling is ductility—the ability to deform under tensile stress without fracturing. The material must be capable of significant plastic deformation to be squeezed and elongated by the rollers.

This is why metals and their alloys are the ideal candidates. Their metallic crystal structure allows atoms to slip past one another, enabling the material to change shape permanently rather than shatter.

Non-Metallic Materials Are Unsuitable

Brittle materials like ceramics, most polymers, and cast iron are generally not rolled. They lack the required ductility and would simply crack and fracture under the immense compressive forces exerted by the rolling mills.

A Closer Look at Common Rolling Materials

While the category is "metals," the specific material chosen depends entirely on the end-use application, dictating needs for strength, weight, conductivity, or corrosion resistance.

Ferrous Metals: The Backbone of Industry

Steel is the most widely rolled material on the planet. This includes carbon steels, stainless steels, and various alloy steels. It is hot-rolled to create structural I-beams, rails for railways, and thick plates, and then often cold-rolled to produce sheet metal for automotive bodies and appliances.

Non-Ferrous Metals: Lightweight and Conductive

Aluminum is prized for its high strength-to-weight ratio, making it essential in aerospace, automotive, and packaging (like beverage cans). Copper is rolled into sheets and strips for its excellent electrical and thermal conductivity, used in everything from electronics to roofing. Alloys like brass and bronze are also rolled for plumbing fittings and bearings.

Specialized and Precious Metals

The rolling process is not limited to industrial metals. High-value materials like titanium, nickel alloys, and precious metals like gold, silver, and platinum are rolled to produce plates, sheets, and foil for specialized aerospace, medical, and jewelry applications.

Hot Rolling vs. Cold Rolling: Process Dictates Properties

The choice between hot or cold rolling is a fundamental decision determined by the material and the desired final characteristics.

Hot Rolling: For Major Shape Reduction

Hot rolling is performed at temperatures above the material's recrystallization point. At these high temperatures, the metal is softer and more malleable, allowing for massive reductions in thickness in a single pass.

This is the primary method for producing foundational shapes like slabs, blooms, and billets from raw ingots.

Cold Rolling: For Precision, Strength, and Finish

Cold rolling is performed below the recrystallization temperature (often at room temperature). This process requires significantly more force but yields products with distinct advantages.

Cold rolling increases the material's strength and hardness through a process called work hardening. It also produces a superior surface finish and allows for much tighter dimensional tolerances, which is critical for final products.

Understanding the Trade-offs

Choosing a material and rolling process involves balancing cost, efficiency, and final product requirements. There is no single "best" method.

The Challenge of Hot Rolling

The primary trade-off with hot rolling is a lack of precision. As the metal cools, it shrinks unpredictably, leading to less precise final dimensions. The high temperatures also cause a scaly, rough surface finish that must often be removed.

The Limitations of Cold Rolling

Cold rolling is more expensive due to the immense power required to shape the harder material. Furthermore, the work-hardening effect reduces the metal's ductility, limiting how much it can be shaped before it requires an annealing (heat treatment) process to restore its formability.

Making the Right Choice for Your Goal

The material and rolling technique must be matched to the engineering goal. Your final application dictates the best path forward.

- If your primary focus is cost-effective, large-scale structural components: Hot-rolled steel is the unmatched standard for creating foundational products like I-beams, channel, and thick plates.

- If your primary focus is a precise, strong part with a smooth finish: Cold-rolled metals like steel, aluminum, or copper are required for automotive panels, appliance casings, and electronic components.

- If your primary focus is balancing formability and final properties: A combination is often used, where a material is first hot-rolled into a manageable shape and then cold-rolled to achieve its final strength and finish.

Ultimately, understanding the interplay between a material's inherent properties and the rolling process is the key to effective and efficient manufacturing.

Summary Table:

| Material Type | Common Examples | Key Applications |

|---|---|---|

| Ferrous Metals | Carbon Steel, Stainless Steel | Structural beams, automotive panels, appliances |

| Non-Ferrous Metals | Aluminum, Copper, Brass | Aerospace, packaging, electronics, roofing |

| Specialized Metals | Titanium, Nickel Alloys, Gold, Silver | Aerospace, medical devices, jewelry |

| Rolling Process | Temperature | Key Outcome |

| Hot Rolling | Above recrystallization point | Major shape reduction, cost-effective large parts |

| Cold Rolling | Below recrystallization point | High precision, strength, smooth finish |

Need precise, high-quality rolled materials for your lab or manufacturing process? KINTEK specializes in providing lab equipment and consumables tailored to your material testing and processing needs. Whether you're working with structural steels, conductive non-ferrous metals, or specialized alloys, our solutions help you achieve the exact properties and finishes required for your applications. Contact our experts today to discuss how we can support your material shaping and testing workflows!

Visual Guide

Related Products

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Single Horizontal Jar Mill

- Laboratory Four-Body Horizontal Jar Mill

- Laboratory Jar Mill with Agate Grinding Jar and Balls

- Laboratory Ten-Body Horizontal Jar Mill for Lab Use

People Also Ask

- What is the difference between hydraulic and mechanical press machines? Choose the Right Force for Your Production

- What is the strength of a hydraulic press? Harnessing Pascal's Principle for Immense Force

- What is a press frame? The Foundation of Precision and Force Management in Presses

- What role does a laboratory hydraulic press play in pellet-type electrode fabrication? Enhancing Solid-State Performance

- Why is a laboratory hydraulic press required for solid-state battery assembly? Essential Tools for Ion Conductivity

- What role do laboratory hydraulic presses and stainless steel molds play in the pre-treatment of LLZO powders? | KINTEK

- What function does a laboratory hydraulic press perform for sulfide electrolytes? Achieve 90%+ Densification Today

- What is the difference between XRF and AAS? Choosing the Right Elemental Analysis Tool