While certain specialized metals like tungsten can be used as crucibles, the best and most common material for a crucible is rarely a metal at all. For the vast majority of foundry and melting applications, composite materials like graphite, silicon carbide, and clay graphite offer a far superior combination of extreme heat resistance, durability, and chemical stability. The "best" choice is not a single material but rather the one whose properties best match the metal you are melting and the process you are using.

The search for the "best" crucible is not about finding a single winner. It's about matching the crucible's properties—its melting point, chemical inertness, and resistance to thermal shock—to the specific material and temperature of your work.

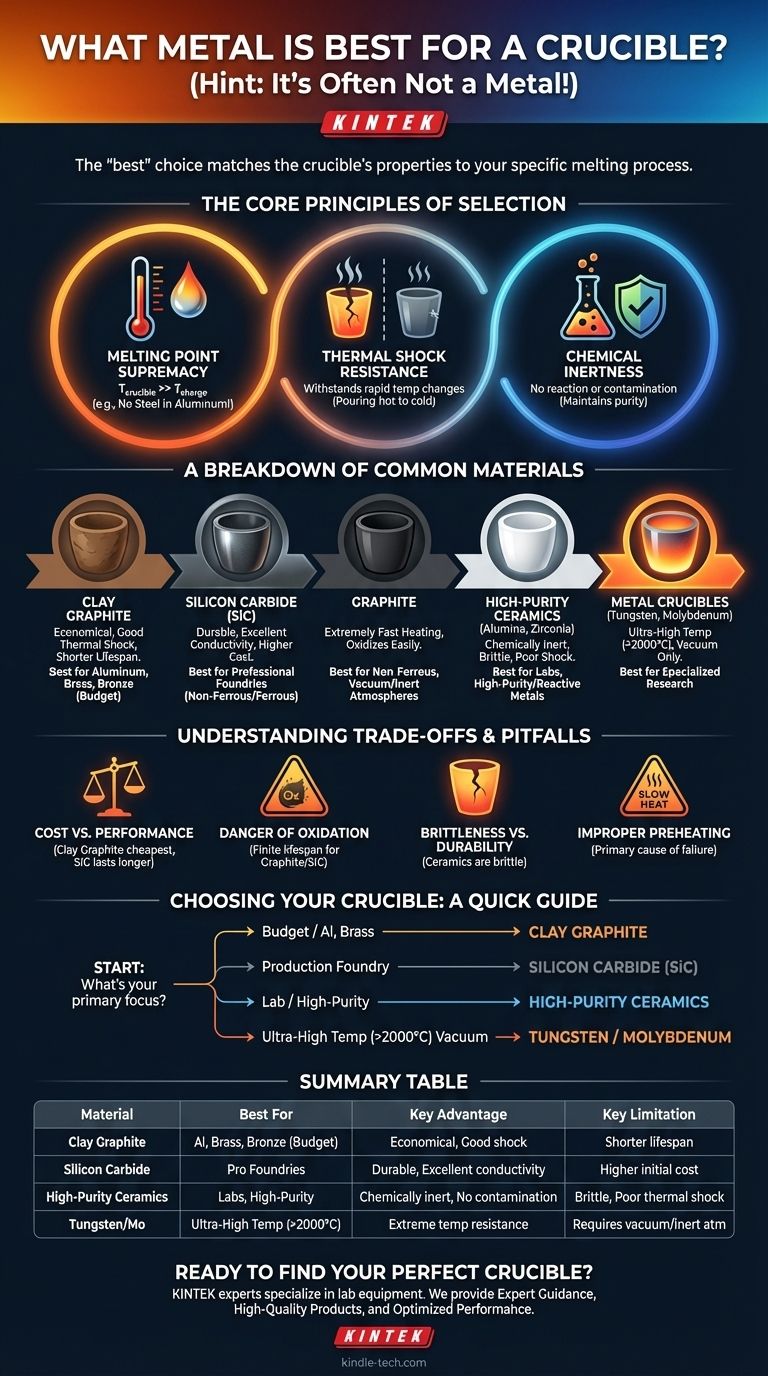

The Core Principles of Crucible Selection

To choose the right crucible, you must think like a materials scientist. A crucible is not just a container; it's a technical component that must withstand some of the most extreme conditions in manufacturing and research. Three properties are paramount.

### Melting Point Supremacy

The most fundamental rule is that a crucible's melting point must be significantly higher than the melting point of the material you are putting inside it, known as the "charge."

For example, attempting to melt steel (melts at ~1500°C / 2750°F) in an aluminum crucible (melts at 660°C / 1220°F) is impossible; the crucible would liquefy first. The crucible material should have a service temperature rating well above your target.

### Thermal Shock Resistance

Thermal shock is the stress a material endures when it undergoes rapid temperature changes. A material with poor thermal shock resistance will crack or shatter when heated or cooled too quickly.

Think of pouring boiling water into a cold, thin glass. A good crucible, like one made of silicon carbide, can withstand being pulled from a glowing-hot furnace and placed on a cooler surface without failing. This durability is critical for safety and operational efficiency.

### Chemical Inertness

A crucible must not react with or contaminate the molten metal it holds. This is crucial for maintaining the purity and desired properties of your final cast product.

For instance, while graphite is excellent for many metals, it will readily dissolve into molten iron, increasing its carbon content and altering its properties. For high-purity steel, a ceramic crucible like magnesia or zirconia would be necessary to avoid this carbon contamination.

A Breakdown of Common Crucible Materials

With the core principles established, we can evaluate the most common materials used for crucibles today.

### Clay Graphite Crucibles

These are the traditional, economical workhorses for many foundries. They are a mixture of flake graphite, clay as a binder, and other refractory materials.

They offer good thermal conductivity and decent resistance to thermal shock, making them ideal for hobbyists and small-scale operations melting non-ferrous metals like aluminum, brass, and bronze.

### Silicon Carbide (SiC) Crucibles

Silicon carbide is a high-performance ceramic that is often combined with graphite to create a superior composite crucible. These are a significant step up in quality and durability from clay graphite.

SiC crucibles offer exceptional strength at high temperatures, excellent thermal conductivity for fast melting, and superior resistance to wear and oxidation. They are the standard choice for professional non-ferrous and many ferrous foundries.

### Graphite Crucibles

While often used in composite form, high-purity graphite crucibles are also common. Their primary advantage is extremely high thermal conductivity, allowing for very rapid and efficient heating of the charge.

However, pure graphite readily oxidizes (burns away) in an oxygen atmosphere at high temperatures, limiting its lifespan. They are best suited for non-ferrous metals and are often used in vacuum or inert-atmosphere furnaces to prevent oxidation.

### High-Purity Ceramic Crucibles

For laboratory work, electronics, or melting reactive or high-purity metals (like titanium or platinum), ceramic crucibles made of alumina, zirconia, or magnesia are required.

These materials offer extremely high melting points and are chemically very stable, preventing any contamination of the melt. Their primary drawback is that they are brittle and have poor thermal shock resistance, requiring very slow and controlled heating and cooling cycles.

### Metal Crucibles (Tungsten, Molybdenum)

Finally, we return to the original question about metals. Metals like tungsten (melting point: 3422°C) and molybdenum (melting point: 2623°C) are used as crucibles for highly specialized, ultra-high-temperature applications.

Their use is almost exclusively limited to vacuum furnaces. This is because these metals react aggressively with oxygen at high temperatures and would be destroyed almost instantly if used in open air. They are used for research and niche industrial processes where even high-end ceramics would fail.

Understanding the Trade-offs and Pitfalls

No single crucible material is perfect for every situation. Understanding their limitations is key to making a wise investment and ensuring safe operation.

### The Cost vs. Performance Spectrum

Clay graphite is the cheapest option but has the shortest service life. Silicon carbide crucibles cost significantly more upfront but last many times longer, making them more economical for frequent use. High-purity ceramic and metal crucibles are orders of magnitude more expensive and reserved for applications where their unique properties are non-negotiable.

### The Danger of Oxidation

Graphite and silicon carbide crucibles will degrade over time in a standard fuel-fired or electric resistance furnace due to oxidation. A protective glaze helps, but their lifespan is finite. This is a primary operational cost to consider.

### Brittleness vs. Durability

A silicon carbide crucible is tough and can handle the rough environment of a foundry. A pure alumina ceramic crucible is brittle and must be handled with extreme care. You are trading mechanical durability for chemical purity.

### Improper Preheating Is a Primary Cause of Failure

The most common mistake new users make is failing to properly preheat a new crucible. Crucibles absorb moisture from the air, and if heated too quickly, this moisture turns to steam and cracks the crucible violently. Always follow the manufacturer's instructions for a slow initial firing to drive out all moisture.

Choosing the Right Crucible for Your Application

To make a definitive choice, align the material with your specific goal, materials, and budget.

- If your primary focus is melting aluminum, brass, or precious metals on a budget: A clay graphite crucible offers the best balance of cost and initial performance.

- If your primary focus is running a production foundry with frequent melts: A silicon carbide (SiC) crucible provides superior durability and a longer service life, justifying the higher initial cost.

- If your primary focus is laboratory research or melting high-purity alloys: A high-purity ceramic crucible like alumina or zirconia is necessary to prevent contamination.

- If your primary focus is melting materials at extreme temperatures (>2000°C) in a vacuum: A specialized metal crucible made of tungsten or molybdenum is your only viable option.

Viewing your crucible not as a simple bucket but as a critical piece of technical equipment is the first step toward achieving clean, safe, and successful melts.

Summary Table:

| Material | Best For | Key Advantage | Key Limitation |

|---|---|---|---|

| Clay Graphite | Aluminum, Brass, Bronze (Budget) | Economical, Good thermal shock | Shorter lifespan |

| Silicon Carbide (SiC) | Professional Foundries (Non-Ferrous/Ferrous) | Durable, Excellent thermal conductivity | Higher initial cost |

| High-Purity Ceramics | Labs, High-Purity/Reactive Metals | Chemically inert, No contamination | Brittle, Poor thermal shock |

| Tungsten/Molybdenum | Ultra-High Temp (>2000°C) in Vacuum | Extreme temperature resistance | Requires vacuum/inert atmosphere |

Ready to Find Your Perfect Crucible?

Choosing the right crucible is critical for the safety, efficiency, and purity of your work. The experts at KINTEK specialize in lab equipment and consumables, helping you select the ideal crucible for your specific application—whether you're melting aluminum, conducting high-purity research, or operating a production foundry.

We provide:

- Expert Guidance: Match your material and process to the best crucible material.

- High-Quality Products: Durable crucibles from trusted manufacturers.

- Optimized Performance: Achieve cleaner melts and longer crucible life.

Don't let the wrong crucible compromise your results. Contact our specialists today for a personalized recommendation!

Visual Guide

Related Products

- Alumina Al2O3 Ceramic Crucible Semicircle Boat with Lid for Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Alumina Al2O3 Ceramic Crucible for Laboratory Muffle Furnace

- Engineering Advanced Fine Ceramics Alumina Al2O3 Crucible With Lid Cylindrical Laboratory Crucible

- High Purity Pure Graphite Crucible for Evaporation

- Arc-Shaped Alumina Ceramic Crucible High Temperature Resistant for Engineering Advanced Fine Ceramics

People Also Ask

- What are the advantages of selecting an alumina crucible for TGA? Ensure High-Precision Thermal Analysis Data

- Why is the use of high-purity alumina crucibles necessary for NMC powders? Ensure Purity in Cathode Synthesis

- What is the function of alumina crucibles in Na3V2(PO4)2F3 synthesis? Ensure Purity in NVPF Production

- What are the functional advantages of using high-purity alumina crucibles? Achieve Precise Oxidation Data

- What are the advantages of high-purity alumina crucibles for molten ZnNaK//Cl salts? Ensure Experimental Purity