To use a tube furnace safely and effectively, you must focus on three core areas: managing thermal stress through controlled heating and cooling, maintaining a clean and stable operating environment, and prioritizing personal safety through proper handling and protective equipment. These precautions are not merely rules; they are essential practices to protect the integrity of your experiment, the longevity of the instrument, and the well-being of the operator.

A tube furnace is a precision instrument, not just a simple oven. Its reliability hinges on respecting the physics of high-temperature materials. The most critical failures—cracked tubes, burned-out elements, and ruined experiments—almost always stem from rapid temperature changes, contamination, or atmospheric mismanagement.

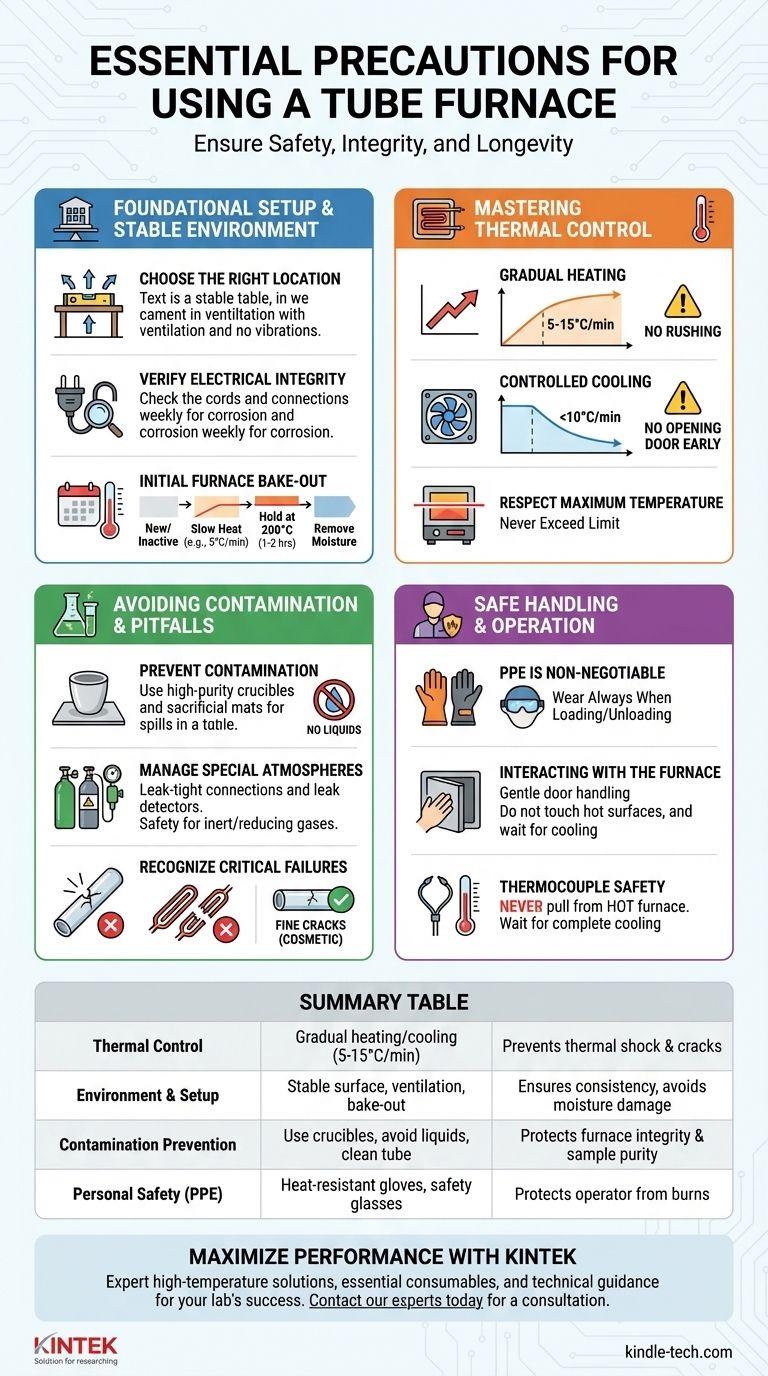

Foundational Setup: Creating a Stable Environment

Before you even turn the furnace on, its location and initial condition set the stage for success or failure. An unstable environment directly translates to unreliable results and safety hazards.

Choosing the Right Location

The furnace must be placed on a solid, level, and vibration-free surface. Vibrations can damage internal components, particularly the delicate furnace tube and heating elements, over time.

Ensure the area is well-ventilated to dissipate heat and any potential off-gassing from your samples. Keep the furnace away from flammable materials, explosives, and sources of moisture.

Verifying Electrical Integrity

Before every use, visually inspect the power cords and connections. At least once a week, perform a more thorough check to ensure all electrical contacts are tight and free of corrosion.

A loose connection can create electrical arcs and pose a significant fire hazard, while also leading to inconsistent power delivery and failed heating cycles.

The Initial Furnace "Bake-Out"

If the furnace is new or has been inactive for a long period, it will have absorbed atmospheric moisture. This moisture must be driven out slowly to prevent damage.

Perform an initial "bake-out" by heating the furnace at a very slow rate (e.g., 5°C/minute) to around 200°C and holding it for an hour or two. This prevents steam from creating pressure or damaging the furnace insulation at higher temperatures.

Mastering Thermal Control: The Key to Longevity

The most common cause of tube furnace damage is thermal shock. The ceramic tube and heating elements are brittle and will crack if heated or cooled too quickly.

The Principle of Gradual Heating

Never rush the heating process, especially in the lower temperature range. The heating rate should be slow and steady, allowing the entire system to expand uniformly.

Set your heating rate based on the properties of your sample and the furnace limits, typically between 5-15°C per minute. Abruptly high heating rates can also cause samples to outgas violently, contaminating the furnace tube.

The Criticality of Controlled Cooling

Controlled cooling is just as important as controlled heating. A split tube furnace, for example, should generally not be cooled faster than 10°C per minute.

Never open the furnace door or cover to "speed up" the cooling process. The sudden influx of cool air will almost certainly crack the hot furnace tube. Allow the furnace to cool down naturally according to its programmed cycle.

Respecting the Maximum Temperature Limit

Every furnace has a maximum operating temperature. Exceeding this limit, even for a short time, can cause permanent damage to the heating elements, insulation, and thermocouples. Always operate well within the specified range.

Understanding the Trade-offs and Common Pitfalls

Operating a tube furnace involves managing risks. Understanding common failure modes helps you prevent them.

The Danger of Contamination

Foreign materials are the enemy of a high-temperature environment. Never inject liquids or dissolved metals directly into the furnace tube.

If you are working with materials that could melt or spill, place them in a high-purity alumina crucible. Consider using sacrificial mats or a layer of aluminum oxide powder on the bottom of the tube to catch any potential spills and protect the tube itself.

Managing Special Atmospheres

If your process requires a specific gas atmosphere (e.g., inert or reducing), ensure all connections are leak-tight. Never introduce flammable or explosive gases without proper safety interlocks, flow controls, and expert supervision.

Water vapor is also a contaminant. It can react with materials at high temperatures and degrade heating elements like silicon carbide rods.

Recognizing Normal Wear vs. Critical Failure

Over many heating cycles, it is normal for fine cracks to appear on the surface of the refractory ceramic insulation. This is typically cosmetic and does not impact performance.

However, a broken or visibly aged heating element (e.g., silicon carbide rod) or a crack in the process tube itself is a critical failure that must be addressed immediately. Power down the furnace and replace the component before further use.

Safe Handling and Operation

Your direct interaction with the furnace carries inherent risks. Following strict protocols is essential.

Personal Protective Equipment (PPE) is Non-Negotiable

Always wear heat-resistant gloves and safety glasses or a face shield when loading or unloading the furnace. Even if the furnace seems cool, internal components can retain heat for a long time.

Interacting with the Furnace

Handle the furnace door gently to avoid jarring and damaging the components. Do not touch any part of the furnace body during operation, as the exterior surfaces can become extremely hot.

Never pull a thermocouple out of a hot furnace. The extreme temperature gradient will destroy it. Wait until the furnace has cooled completely before performing any maintenance or adjustments.

A Practical Checklist for Every Experiment

Use this framework to ensure a safe and successful run every time.

- Before you begin: Confirm the furnace is on a stable surface, check all power connections, and ensure the furnace tube is clean and free of contaminants.

- During operation: Adhere strictly to programmed heating and cooling rates, never exceed the temperature limit, and always wear appropriate PPE when near the unit.

- After the experiment: Follow the complete, programmed shutdown procedure, allow the furnace to cool below 100°C before opening, and perform a visual inspection for any spills or damage.

By treating the tube furnace as the sensitive instrument it is, you ensure not only your safety but also the accuracy and repeatability of your results.

Summary Table:

| Precaution Category | Key Action | Why It Matters |

|---|---|---|

| Thermal Control | Gradual heating/cooling (5-15°C/min) | Prevents thermal shock & cracks in tubes/elements |

| Environment & Setup | Stable surface, good ventilation, initial bake-out | Ensures consistent results and prevents moisture damage |

| Contamination Prevention | Use crucibles, avoid liquids, clean tube | Protects furnace integrity and sample purity |

| Personal Safety (PPE) | Heat-resistant gloves, safety glasses | Protects operator from burns and other hazards |

Maximize the performance and lifespan of your lab equipment with KINTEK.

Our expertise in high-temperature laboratory solutions ensures you have the right tools and knowledge for safe and effective operations. Whether you need a reliable tube furnace, essential consumables, or technical guidance to optimize your processes, KINTEK is here to support your laboratory's success.

Contact our experts today for a consultation on the ideal furnace for your application and to learn how we can help you achieve precise, repeatable results safely.

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Laboratory High Pressure Vacuum Tube Furnace

- Vertical Laboratory Tube Furnace

People Also Ask

- What can you use glass tubes for? Essential Applications in Labs, Industry, and Design

- What is the resistance of quartz? Discover Its Superior Insulating Properties

- At what temperature range does pyrolysis start at? Control Your Output from Biochar to Syngas

- How does a quartz tube furnace facilitate the synthesis of rGO? Optimize Your Cathode Matrix with Precise Pyrolysis

- Why Is a Tube Furnace Essential for Carbon Nanotube Synthesis? Master Precision in Waste-to-CNT Pyrolysis

- What is the core function of high-temperature carbonization at 800 °C in a tube furnace? Optimize Electrocatalysts

- What is the primary function of a high-temperature tube furnace in pre-oxidation? Master Surface Engineering of Steels

- What is the difference between a tube furnace and a muffle furnace? Choose the Right Tool for Your Lab's Heating Needs