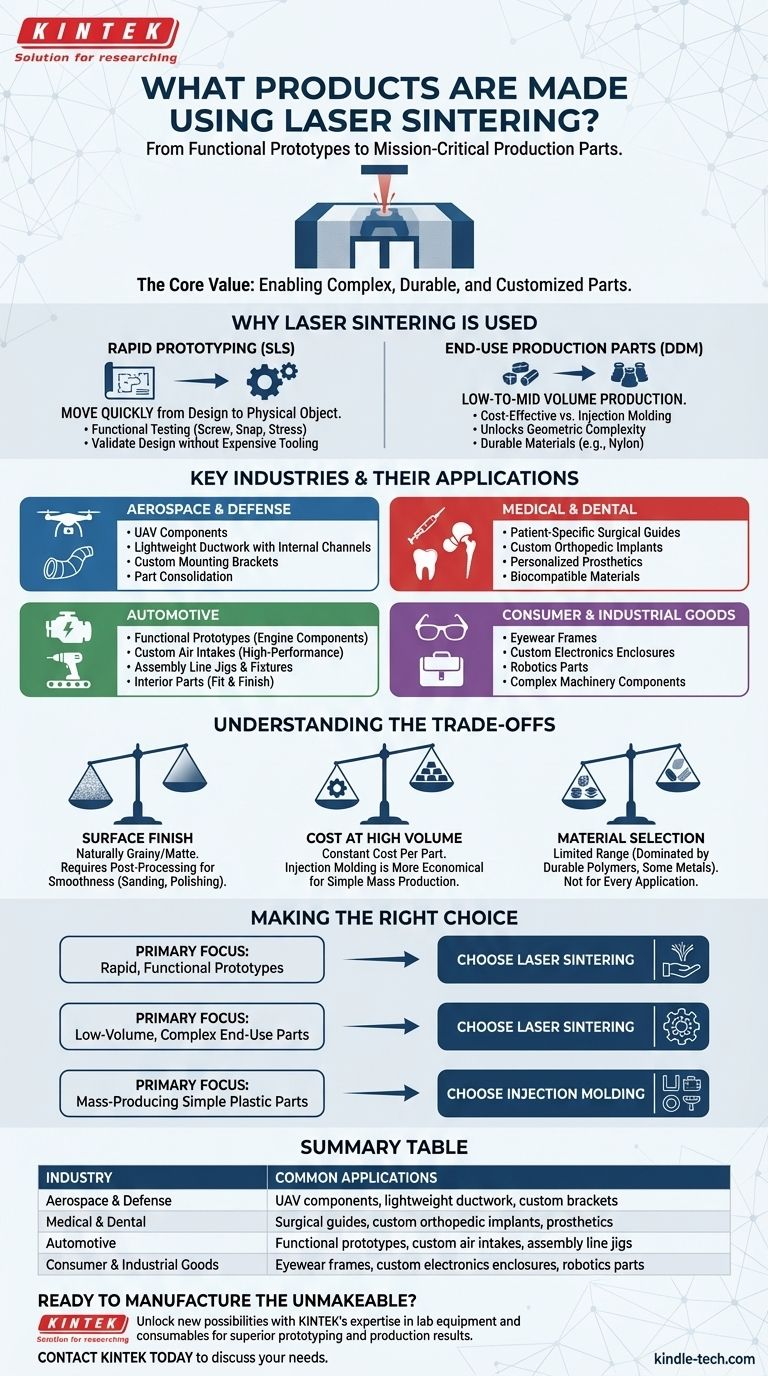

At its core, laser sintering is used to create a vast range of products, from early-stage functional prototypes to mission-critical production parts. You will find its applications in industries like aerospace, where it builds complex drone components, and in medicine, where it produces patient-specific surgical implants.

The primary value of laser sintering is not in replacing traditional manufacturing, but in enabling the creation of complex, durable, and often customized parts that would be prohibitively expensive or physically impossible to make otherwise.

Why Laser Sintering Is Used: From Prototypes to Production

Laser sintering, often called Selective Laser Sintering (SLS), is a mature additive manufacturing process valued for two distinct capabilities: creating realistic prototypes and manufacturing finished goods.

The Power of Rapid Prototyping

Engineers use laser sintering to quickly move from a digital design to a physical object. Unlike some other 3D printing methods, the parts are robust.

This allows for functional testing. A sintered prototype isn't just for looks; it can be screwed, snapped, stressed, and tested in a real-world assembly, validating a design long before committing to expensive tooling.

The Shift to End-Use Production Parts

The strength and durability of sintered materials, particularly polymers like nylon, are high enough for final products. This is often called Direct Digital Manufacturing (DDM).

This is most valuable for low-to-mid volume production runs where the cost of creating a traditional mold for injection molding would be too high. It also unlocks geometric complexity that molding cannot achieve.

Key Industries and Their Applications

The decision to use laser sintering is driven by the need for specific material properties, complex geometries, or customization.

Aerospace and Defense

In this sector, weight reduction and performance are paramount. Laser sintering allows for part consolidation, where multiple simple components are redesigned into a single, complex, and lightweight part.

Common products include unmanned aerial vehicle (UAV) components, complex ductwork with internal channels, and custom mounting brackets.

Medical and Dental

Customization is the key driver in medicine. Laser sintering is used to create patient-specific products directly from CT or MRI scan data.

This includes surgical guides that show a surgeon precisely where to cut, custom orthopedic implants like hip or knee replacements, and personalized prosthetics that offer a perfect fit. Biocompatible materials are often used for these applications.

Automotive

The automotive industry uses laser sintering across the entire product lifecycle. It's heavily used for creating functional prototypes of engine components, interior parts, and enclosures for fit and finish checks.

For high-performance and luxury vehicles, it's also used to produce end-use parts like custom air intakes, jigs and fixtures for the assembly line, and other low-volume components.

Consumer and Industrial Goods

Laser sintering provides designers with immense freedom. It's used to create products with intricate patterns and shapes that would be impossible to mold.

Examples range from high-end eyewear frames and custom electronics enclosures to complex components for industrial machinery and robotics.

Understanding the Trade-offs

While powerful, laser sintering is not the solution for every manufacturing problem. Understanding its limitations is key to using it effectively.

Surface Finish

Parts made with laser sintering naturally have a slightly grainy, matte surface finish. While this is often acceptable, achieving a smooth, glossy surface requires post-processing steps like sanding, polishing, or coating, which add time and cost.

Cost at High Volume

The process builds parts layer by layer, and the cost per part remains relatively constant regardless of quantity. For simple parts needed in the tens of thousands, traditional methods like injection molding become vastly more cost-effective once the initial tooling cost is absorbed.

Material Selection

While the range of materials for laser sintering is growing, it is still more limited than traditional manufacturing. The process is dominated by durable polymers like nylon (PA12, PA11) and, in a related process (DMLS/SLM), metals like aluminum, titanium, and stainless steel.

Making the Right Choice for Your Goal

To determine if laser sintering fits your needs, consider your primary objective.

- If your primary focus is rapid, functional prototypes: Laser sintering is an exceptional choice for creating strong parts you can physically test and validate quickly.

- If your primary focus is low-volume, complex end-use parts: This technology is ideal for producing geometries that are too complex or expensive for traditional tooling.

- If your primary focus is mass-producing simple plastic parts: A conventional high-volume method like injection molding will almost always be more economical.

Ultimately, laser sintering empowers engineers and designers to manufacture the previously unmakeable, shifting focus from design-for-manufacturing to manufacturing-for-design.

Summary Table:

| Industry | Common Laser Sintering Applications |

|---|---|

| Aerospace & Defense | UAV components, lightweight ductwork, custom brackets |

| Medical & Dental | Surgical guides, custom orthopedic implants, prosthetics |

| Automotive | Functional prototypes, custom air intakes, assembly line jigs |

| Consumer & Industrial Goods | Eyewear frames, custom electronics enclosures, robotics parts |

Ready to manufacture the unmakeable?

Laser sintering from KINTEK unlocks new possibilities for your lab's prototyping and production. Whether you need durable functional prototypes for testing or complex, low-volume end-use parts, our expertise in lab equipment and consumables can help you achieve superior results.

Contact KINTEK today to discuss how our solutions can enhance your design and manufacturing capabilities.

Visual Guide

Related Products

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Polygon Press Mold for Lab

- Assemble Lab Cylindrical Press Mold

- Special Shape Press Mold for Lab

- Automatic Laboratory Heat Press Machine

People Also Ask

- What is sintering temperature? Mastering the Key to Powdered Material Performance

- How do activators function in SHS coating? Master Gas-Phase Transport for Rapid Coating Deposition

- What are the 5 heat treatment processes? Master Annealing, Hardening, Tempering & More

- Why is a laboratory vacuum drying oven or a high-vacuum manifold essential for recovered monomers and catalysts?

- What is the difference between pyrolysis and catalytic cracking? A Guide to Process Selection

- How does plasma sputtering work? Master Precision Thin-Film Deposition

- What is the difference between hot air oven and laboratory incubator? Choose the Right Thermal Instrument

- Can carbon fiber be conductive? A Guide to Its Electrical Properties and Risks