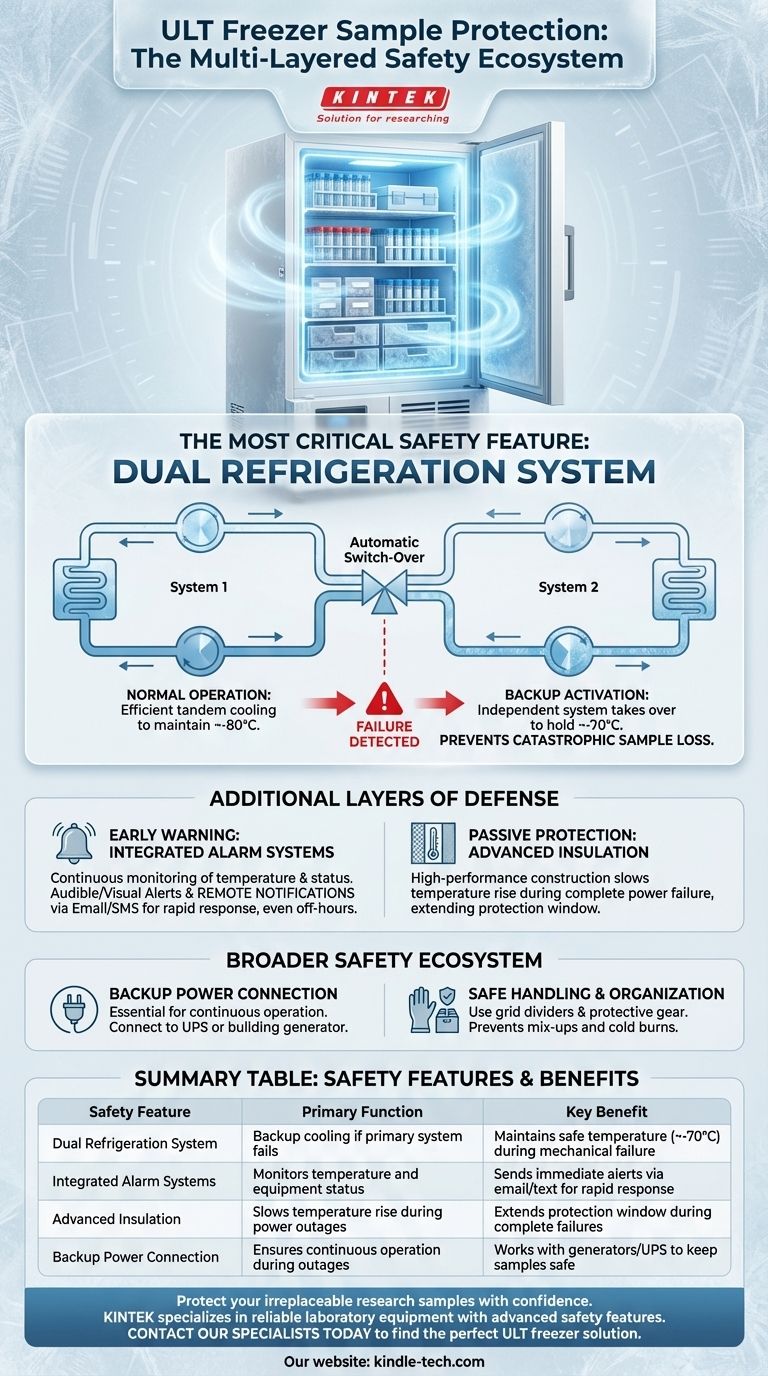

The most critical safety feature in modern ultra-low temperature (ULT) freezers designed to protect samples is the dual refrigeration system. This design provides essential redundancy; if one primary cooling system fails, a secondary, independent system automatically takes over to maintain a stable, safe temperature. This prevents catastrophic sample loss by ensuring the freezer's internal environment remains well below critical thresholds until the primary system can be repaired.

The core principle behind ULT freezer safety is not a single feature, but a strategy of redundancy and rapid notification. A dual refrigeration system acts as the first line of defense against mechanical failure, while integrated alarm systems provide the critical alert needed for human intervention.

How ULT Freezers Ensure Sample Integrity

To protect valuable and often irreplaceable biological samples, ULT freezers rely on a multi-layered approach. Each layer is designed to mitigate a different type of risk, from mechanical breakdown to power outages.

The Principle of Redundancy: Dual Refrigeration

A dual refrigeration system consists of two independent cooling circuits. During normal operation, they may work in tandem to efficiently maintain the target temperature, often around -80°C.

If one compressor or circuit fails, the backup system is powerful enough to single-handedly maintain a safe temperature, typically holding at approximately -70°C. This prevents the rapid warming that would occur in a single-system freezer, protecting sample viability.

This feature is the most important safeguard against a single point of mechanical failure, which is a common cause of freezer malfunctions.

Early Warning: The Role of Alarm Systems

Redundancy is effective, but it requires a corresponding notification system. Nearly all ULT freezers are equipped with sophisticated alarms.

These systems monitor temperature and equipment status continuously. If the internal temperature rises above a set point or a system failure is detected, the alarm will trigger audible and visual alerts.

Crucially, these alarms often include remote notification capabilities, sending alerts via email or text message to lab managers and technicians. This ensures a rapid response even if the failure occurs outside of working hours.

Passive Protection: Advanced Insulation

The final layer of defense is the freezer's physical construction. High-performance insulation is critical for slowing the rate of temperature change during a complete power failure.

Even if both cooling systems were to fail simultaneously due to a power outage, superior insulation provides a longer window of time before the internal temperature reaches a critical point. This extends the grace period for moving samples to a backup unit or resolving the power issue.

Understanding the Broader Safety Ecosystem

The freezer's built-in features are only one part of a comprehensive sample protection strategy. True security depends on integrating the equipment into a well-planned laboratory environment.

The Critical Need for Backup Power

A dual refrigeration system is rendered useless without electricity. For this reason, it is standard procedure to connect any ULT freezer containing critical samples to a backup power source.

This can be an uninterruptible power supply (UPS) for short-term protection or, more commonly, a connection to a building's emergency generator for long-term outages.

Safe Handling and Organization

Proper sample management within the freezer contributes to overall safety. Using organized storage boxes with grid dividers for polymer tubes and microtubes prevents sample mix-ups and damage during retrieval.

Furthermore, personnel must use appropriate protective gear, such as insulated gloves, to prevent cold burns when handling materials stored at such extreme temperatures.

Making the Right Choice for Your Goal

When evaluating a ULT freezer, consider how its features align with your lab's specific priorities.

- If your primary focus is protecting high-value, irreplaceable samples: Prioritize a freezer with a proven dual refrigeration system and a reliable remote alarm system above all else.

- If your primary focus is ensuring operational continuity: Your main concern should be integrating the freezer with a dedicated backup power supply and establishing clear emergency protocols for your team.

- If your primary focus is balancing safety with long-term cost: Look for models that combine these critical safety features with modern energy-saving modes and advanced insulation to minimize operational expenses.

Ultimately, these integrated safety systems are designed to provide the peace of mind necessary to conduct long-term, high-stakes research.

Summary Table:

| Safety Feature | Primary Function | Key Benefit |

|---|---|---|

| Dual Refrigeration System | Provides backup cooling if primary system fails | Maintains safe temperature (~-70°C) during mechanical failure |

| Integrated Alarm Systems | Monitors temperature and equipment status | Sends immediate alerts via email/text for rapid response |

| Advanced Insulation | Slows temperature rise during power outages | Extends protection window during complete failures |

| Backup Power Connection | Ensures continuous operation during outages | Works with generators/UPS to keep samples safe |

Protect your irreplaceable research samples with confidence. KINTEK specializes in reliable laboratory equipment, including ultra-low temperature freezers with advanced safety features like dual refrigeration systems and remote alarm notifications. Our expertise ensures your valuable samples remain secure at optimal conditions. Contact our lab equipment specialists today to find the perfect ULT freezer solution for your laboratory's specific needs and budget.

Visual Guide

Related Products

- 408L Advanced Vertical Laboratory Ultra Low Temperature Freezer for Critical Research Material Preservation

- 108L Vertical Ultra Low Temperature ULT Freezer

- 508L Advanced Vertical Ultra Low Temperature Freezer for Critical Laboratory Storage

- 708L Ultra Low Temperature Freezer High Performance Laboratory Freezer

- 208L Advanced Precision Laboratory Ultra Low Temperature Freezer for Cold Storage

People Also Ask

- What are the key features to look for in an ultra-low temperature freezer for mRNA vaccine storage? Essential Features for Absolute Vaccine Integrity

- How are advancements in compressor technology and refrigerant fluids improving ULT freezers? Boost Efficiency & Cut Costs

- How is temperature controlled in ultra low temperature freezers? A Guide to Stable -80°C Storage

- What are ultra-low temperature freezers designed for? Preserving Your Most Valuable Biological Samples

- Why are ULT freezers considered vital equipment in labs? Ensuring Uncompromised Sample Integrity for Critical Research