To ensure safety during temperature control of a double-layer water-bath electrolytic cell, you must focus on two primary areas: preventing physical burns by avoiding contact with hot surfaces and maintaining precise temperature regulation to protect both your experimental results and the apparatus itself from damage. This involves not only careful operation but also understanding the material limitations of the cell's components.

Your primary goal is to create a stable, controlled environment. This means that safety protocols extend beyond simply avoiding burns; they are integral to protecting the integrity of your equipment and the validity of your data.

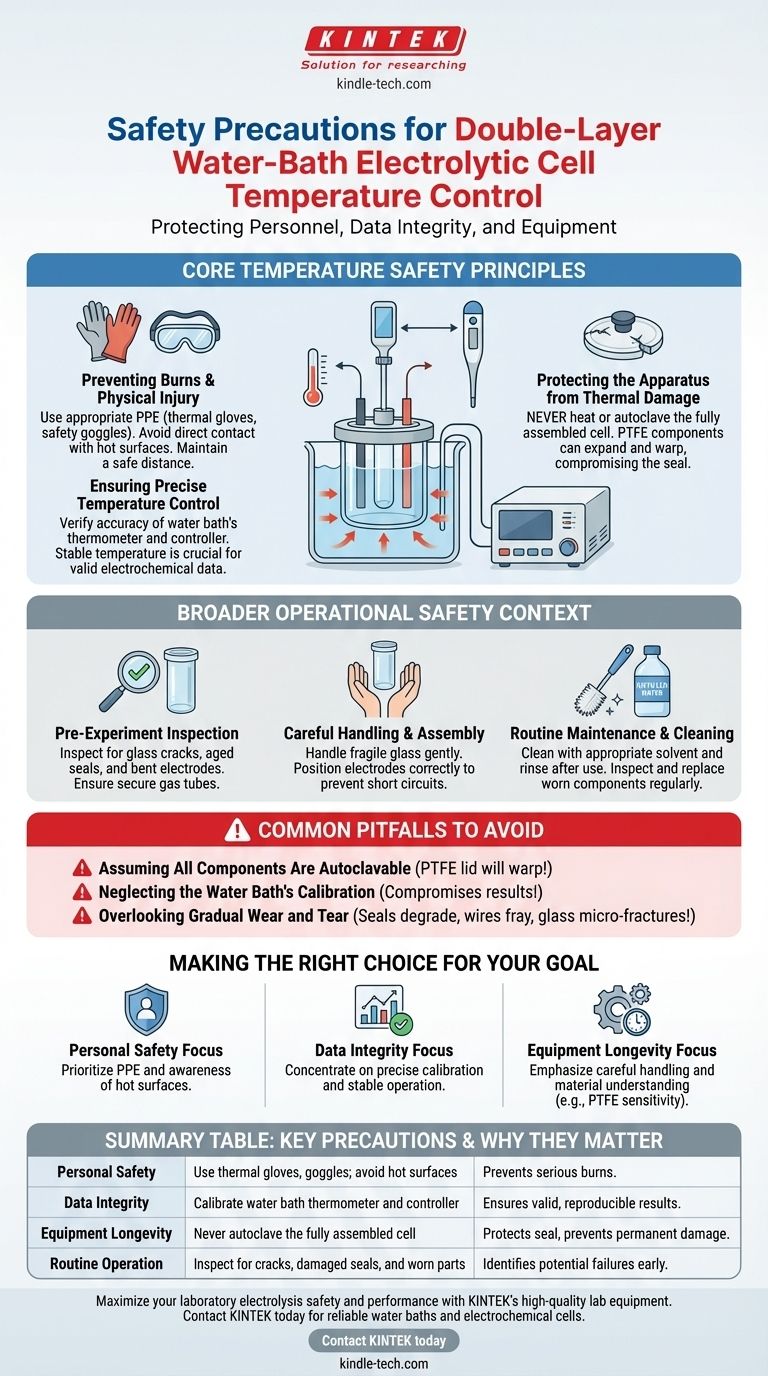

Core Temperature Safety Principles

Effective temperature management is a foundational requirement for both safety and successful experimentation. It requires attention to personal protection, instrument calibration, and the physical limits of the cell.

Preventing Burns and Physical Injury

The most immediate risk is physical harm from high temperatures. The water bath apparatus and the electrolytic cell can become hot enough to cause serious burns.

Always use appropriate Personal Protective Equipment (PPE), such as thermal gloves and safety goggles, especially when handling the cell or adjusting the setup. Maintain a safe distance and avoid direct skin contact with any heated component.

Ensuring Precise Temperature Control

Strict control over the water bath temperature is critical. Temperatures that are too high or too low can significantly alter experimental results, rendering your data invalid.

Before starting, verify the accuracy of the water bath's thermometer and temperature controller. These instruments must function correctly to maintain the stable environment required for reliable electrochemical measurements.

Protecting the Apparatus from Thermal Damage

The electrolytic cell is often constructed from multiple materials with different thermal properties. The cell body may be glass, but components like the lid are often made of PTFE (Teflon).

PTFE can expand when heated and may not return to its original shape upon cooling. For this reason, you should never heat or autoclave the fully assembled cell at high temperatures, as it can permanently damage the lid and compromise the cell's seal.

Broader Operational Safety Context

Temperature control is just one piece of a larger safety framework. To operate the cell safely, you must incorporate a full cycle of inspection, careful handling, and routine maintenance.

Pre-Experiment Inspection is Non-Negotiable

Before every use, perform a thorough inspection of the entire apparatus.

Confirm that the glass cell is free of cracks, the seals are not aged or damaged, and the electrodes are not bent or deformed. Ensure all gas tubes and connections are secure.

Careful Handling and Assembly

The main body of the cell is made of glass, making it fragile. Always handle it gently to prevent breakage.

When installing electrodes, ensure they are positioned correctly and are not making contact with the cell walls or each other, which could create a short circuit.

Routine Maintenance and Cleaning

Regular upkeep is essential for long-term safety and performance.

After use, clean the cell with an appropriate solvent and rinse with distilled water to remove any residual electrolyte. Routinely inspect all parts for wear and tear, replacing any aging or damaged components promptly.

Common Pitfalls to Avoid

Certain assumptions can lead to damaged equipment or failed experiments. Being aware of these common mistakes is critical for safe and effective operation.

Assuming All Components Are Autoclavable

The most frequent and costly mistake is assuming the entire cell can be sterilized at high temperatures. As noted, the PTFE lid will likely warp, destroying the crucial seal and rendering the cell unusable.

Neglecting the Water Bath's Calibration

Trusting the water bath's digital display without verification is a significant risk. An uncalibrated or malfunctioning controller can lead to incorrect temperatures, silently compromising your results and potentially damaging the cell.

Overlooking Gradual Wear and Tear

Safety is an ongoing process, not a one-time check. Seals degrade, wires can fray, and glass can develop micro-fractures over time. Regular inspections are necessary to catch these issues before they lead to a failure or accident.

Making the Right Choice for Your Goal

Adopting a safety-first mindset ensures protection for yourself, your equipment, and your research. Tailor your focus based on your immediate priority.

- If your primary focus is personal safety: Prioritize using proper PPE and always remain aware of hot surfaces to prevent burns.

- If your primary focus is data integrity: Concentrate on the precise calibration and stable operation of your constant temperature water bath.

- If your primary focus is equipment longevity: Emphasize careful handling of the glass and a deep understanding of the material limitations, especially the thermal sensitivity of PTFE components.

Ultimately, rigorous safety protocols are the bedrock of reliable and repeatable scientific outcomes.

Summary Table:

| Safety Focus | Key Precaution | Why It Matters |

|---|---|---|

| Personal Safety | Use thermal gloves and goggles; avoid skin contact with hot surfaces. | Prevents serious burns from heated apparatus. |

| Data Integrity | Calibrate the water bath's thermometer and controller before use. | Ensures stable temperature for valid, reproducible results. |

| Equipment Longevity | Never autoclave the fully assembled cell; PTFE lids can warp. | Protects the cell's seal and prevents permanent damage. |

| Routine Operation | Inspect for cracks, damaged seals, and worn components before each use. | Identifies potential failures before they cause accidents or data loss. |

Maximize the safety and performance of your laboratory electrolysis. Proper temperature control is critical for protecting both your team and your research integrity. KINTEK specializes in high-quality lab equipment and consumables, including reliable water baths and electrochemical cells designed for precise, safe operation. Let our experts help you select the right apparatus for your specific needs. Contact KINTEK today to ensure your lab operates safely and efficiently.

Visual Guide

Related Products

- Double-Layer Water Bath Electrolytic Electrochemical Cell

- Double Layer Five-Port Water Bath Electrolytic Electrochemical Cell

- H-Type Double-Layer Optical Electrolytic Electrochemical Cell with Water Bath

- Electrolytic Electrochemical Cell with Five-Port

- Multifunctional Electrolytic Electrochemical Cell Water Bath Single Layer Double Layer

People Also Ask

- What are the procedures for after using a double-layer water-bath electrolytic cell? Ensure Equipment Longevity and Data Accuracy

- How should a double-layer water-bath electrolytic cell be operated? A Step-by-Step Guide for Reliable Results

- When is professional repair required for a double-layer water-bath electrolytic cell? Protect Your Lab's Precision and Safety

- What are the key features of a double-layer water-bath electrolytic cell? Achieve Precise Temperature Control for Your Experiments

- What are the typical volumes and aperture configurations for a double-layer water-bath electrolytic cell? Optimize Your Electrochemical Setup