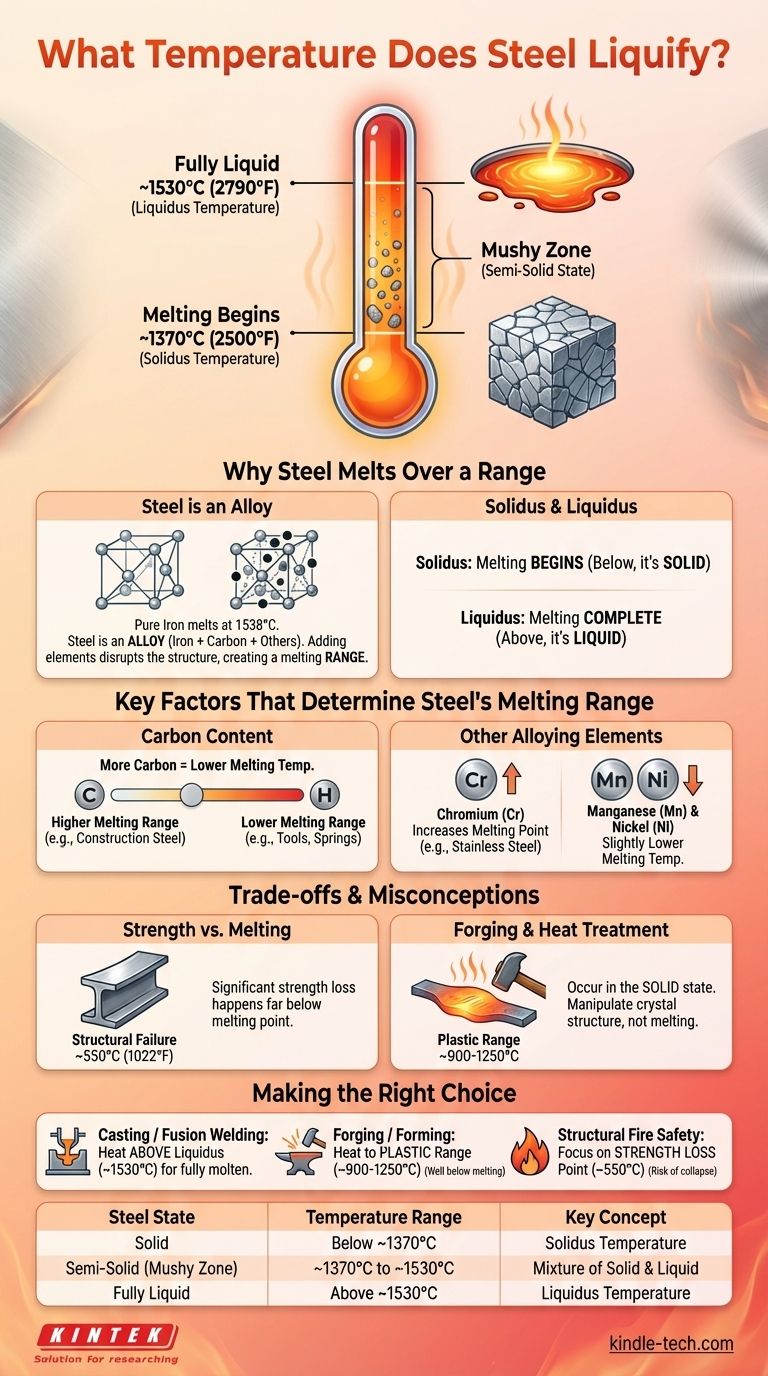

The melting point of steel is not a single number, but a range. For most common types of steel, melting begins at approximately 1370°C (2500°F) and the steel becomes fully liquid by around 1530°C (2790°F). This range exists because steel is an alloy, and its precise melting behavior is determined by its specific chemical composition.

The core principle to understand is that steel does not instantly switch from solid to liquid. Instead, it enters a "mushy" or semi-solid state over a range of temperatures, and the exact points at which it starts and finishes melting depend entirely on the elements alloyed with the iron.

Why Steel Melts Over a Range

Understanding the melting process of steel requires moving beyond the idea of a single melting point, which only applies to pure elements.

Steel is an Alloy, Not a Pure Element

Pure iron has a fixed melting point of 1538°C (2800°F). However, steel is fundamentally an alloy of iron and carbon, often with other elements mixed in.

Adding other elements to a pure metal disrupts its crystalline structure. This change in chemistry means the alloy no longer melts at a single, sharp temperature.

The Solidus and Liquidus Temperatures

Instead of a melting point, alloys like steel have a melting range defined by two critical temperatures:

- Solidus: The temperature at which melting begins. Below this point, the steel is completely solid.

- Liquidus: The temperature at which melting is complete. Above this point, the steel is completely liquid.

Between the solidus and liquidus temperatures, the steel exists in a semi-solid, slushy state containing both solid crystals and molten metal. This is often called the mushy zone.

Key Factors That Determine Steel's Melting Range

The width and position of this melting range are primarily controlled by the steel's chemical makeup.

The Critical Role of Carbon

Carbon is the most significant alloying element in steel. Its presence has a profound effect on the melting point.

Generally, increasing the carbon content lowers steel's melting temperature. A low-carbon steel (like those used in construction) will have a higher melting range than a high-carbon steel (used for tools and springs).

Influence of Other Alloying Elements

Other elements are added to create specific properties, such as strength or corrosion resistance, and they also alter the melting range.

- Chromium, a key ingredient in stainless steel, tends to increase the melting point.

- Manganese and Nickel are common additions that can slightly lower the melting temperatures.

Because of this complex interplay, a specific material data sheet is required to know the exact solidus and liquidus for any given grade of steel.

Understanding the Trade-offs and Misconceptions

It's easy to misinterpret what "melting" means in a practical context. The loss of structural integrity happens long before the material becomes liquid.

Strength vs. Melting

A common pitfall is to equate the melting point with the point of failure. Steel loses a significant amount of its strength at temperatures far below its melting point.

For structural steel used in buildings, a temperature of 550°C (1022°F) is often considered the point of critical failure, as it has lost about half of its room-temperature strength, making it unable to support its design load.

Forging and Heat Treatment are Not Melting

Processes like forging, hardening, and annealing involve heating steel to very high temperatures, but they all occur while the steel is completely solid.

These processes manipulate the steel's crystal structure in its solid state to change its mechanical properties. They do not involve any partial or full melting.

Making the Right Choice for Your Goal

Your reason for asking about steel's melting point dictates which temperature is most important.

- If your primary focus is casting or fusion welding: You must heat the material above its liquidus temperature (around 1530°C / 2790°F) to ensure it is fully molten and will flow or fuse correctly.

- If your primary focus is forging or forming: You need to heat the steel to its plastic range, which is well below the melting point, typically between 900°C and 1250°C (1650°F and 2280°F).

- If your primary focus is structural fire safety: The critical temperature is not the melting point but the point of strength loss, often cited as 550°C (1022°F), where structural collapse becomes a risk.

Recognizing that steel's behavior under heat is a spectrum, not a single event, is the key to using it safely and effectively.

Summary Table:

| Steel State | Temperature Range | Key Concept |

|---|---|---|

| Solid | Below ~1370°C (2500°F) | Solidus Temperature (Melting Begins) |

| Semi-Solid (Mushy Zone) | ~1370°C to ~1530°C | Mixture of Solid & Liquid |

| Fully Liquid | Above ~1530°C (2790°F) | Liquidus Temperature (Melting Complete) |

Need precise thermal processing for your steel applications? KINTEK specializes in high-temperature lab equipment, including furnaces that accurately control the melting and heat treatment ranges discussed here. Whether you're involved in materials testing, metallurgy, or R&D, our solutions ensure safety and precision. Contact our experts today to find the right equipment for your laboratory's needs.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- Can you melt metal to reuse it? Unlock the Secrets of Metal Casting and Recycling

- How does induction furnace work? Achieve Fast, Clean, and Efficient Metal Melting

- What are the disadvantages of coreless type induction furnace? Key Trade-offs in Flexibility vs. Efficiency

- What does induction heating depend on? Master the 4 Key Factors for Precision Heating

- How many times can metal be melted down and used again? The Key to Infinite Recyclability

- What are the disadvantages of induction furnace? Key Limitations for Metal Melting

- What is the process of melting in an induction furnace? Harnessing Electromagnetic Power for Efficient Metal Melting

- What is the role of Vacuum Induction Melting Furnaces in nickel-based alloy prep? Achieve Ultimate Chemical Purity