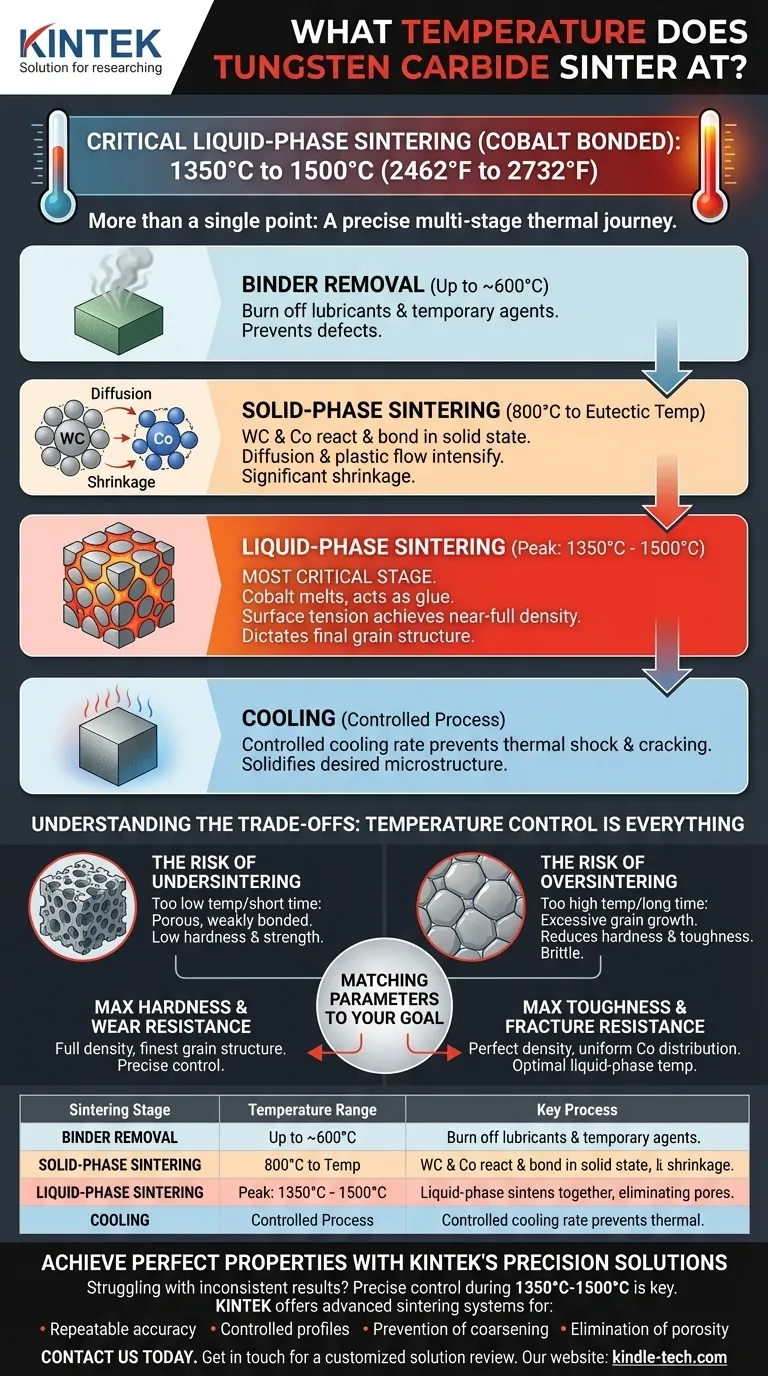

For tungsten carbide bonded with cobalt, the critical liquid-phase sintering occurs at a peak temperature typically ranging from 1350°C to 1500°C (2462°F to 2732°F). This is not a single point but the culmination of a carefully controlled heating process where the cobalt binder melts and fuses the tungsten carbide grains into a solid, dense mass.

Sintering tungsten carbide is not about reaching a single temperature. It is a precise, multi-stage thermal process where the final material properties are determined by the temperature profile, particularly the peak temperature reached during the liquid-phase stage.

The Four Stages of Tungsten Carbide Sintering

To understand why a temperature range is more accurate than a single number, you must understand the journey the material takes. The process is typically divided into four distinct stages, each occurring at a different temperature range and serving a unique purpose.

Stage 1: Binder Removal (Up to ~600°C)

Before true sintering begins, the compacted raw material (called "green" compact) is gently heated.

This initial stage burns off any pressing lubricants or temporary molding agents used to shape the part. This step is critical for preventing defects in the final product.

Stage 2: Solid-Phase Sintering (800°C to Eutectic Temperature)

As the temperature rises past 800°C, the tungsten carbide (WC) grains and cobalt (Co) particles begin to react and bond while still in their solid state.

During this phase, diffusion and plastic flow intensify. The part shrinks significantly as the particles rearrange and pack more closely, but no melting has occurred yet.

The end of this stage is defined by the eutectic temperature, which is the lowest temperature at which the cobalt binder alloy can begin to melt.

Stage 3: Liquid-Phase Sintering (Peak Temperature: 1350°C - 1500°C)

This is the most critical stage. The furnace temperature is raised above the eutectic point, causing the cobalt binder to melt and become a liquid.

This liquid cobalt acts like a powerful glue. Through surface tension, it pulls the solid tungsten carbide grains tightly together, eliminating the remaining pores and achieving near-full density. The precise peak temperature and the time spent there dictate the final grain structure.

Stage 4: Cooling

The final stage is a controlled cooling process. The rate of cooling is managed carefully to prevent thermal shock, which could cause cracking, and to solidify the desired microstructure of the finished carbide part.

Understanding the Trade-offs: Temperature Control is Everything

Achieving the correct peak sintering temperature is a balancing act. Minor deviations can have a significant impact on the final material's performance.

The Risk of Undersintering

If the peak temperature is too low or the hold time is too short, the cobalt binder may not fully melt or distribute evenly.

This results in a porous and weakly bonded material. The part will lack the required hardness, strength, and wear resistance.

The Risk of Oversintering

If the temperature is too high or the hold time is too long, the tungsten carbide grains will grow excessively large.

While the part will be fully dense, this coarse grain structure reduces hardness and toughness, making the material more brittle and less effective in demanding applications.

Matching Sintering Parameters to Your Goal

The ideal sintering profile depends directly on the desired properties of the final product.

- If your primary focus is maximum hardness and wear resistance: The goal is to achieve full density with the finest possible grain structure, requiring precise control to avoid excessive temperatures or hold times.

- If your primary focus is maximum toughness and fracture resistance: The goal is a perfectly dense part with uniform cobalt distribution, which demands reaching the optimal liquid-phase temperature to ensure complete pore elimination.

Ultimately, mastering the sintering of tungsten carbide is about the precise and repeatable control of its entire thermal journey.

Summary Table:

| Sintering Stage | Temperature Range | Key Process |

|---|---|---|

| Binder Removal | Up to ~600°C | Burn off lubricants/molding agents |

| Solid-Phase Sintering | 800°C to Eutectic Temp | WC/Co diffusion & particle bonding |

| Liquid-Phase Sintering | 1350°C - 1500°C | Cobalt melts, densifies WC grains |

| Controlled Cooling | Gradual decrease | Solidify microstructure, prevent cracking |

Achieve Perfect Tungsten Carbide Properties with KINTEK's Precision Sintering Solutions

Are you struggling with porous, brittle, or inconsistent tungsten carbide results? The difference between superior performance and product failure lies in precise temperature control during the 1350°C-1500°C liquid-phase sintering stage.

KINTEK specializes in laboratory sintering equipment and consumables that deliver the exact thermal profiles needed for your specific application—whether you require maximum hardness for wear resistance or optimal toughness for fracture resistance.

Our advanced sintering systems provide:

- Repeatable temperature accuracy within critical liquid-phase ranges

- Controlled multi-stage heating profiles for complete densification

- Prevention of grain coarsening that reduces material hardness

- Elimination of porosity that weakens final products

Contact us today to discuss how KINTEK's sintering expertise can help you achieve consistent, high-performance tungsten carbide components. Get in touch with our experts for a customized solution review.

Visual Guide

Related Products

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Laboratory High Pressure Vacuum Tube Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What are the advantages of using a vacuum hot pressing furnace? Achieve 98.9% Density in Al2O3-TiC Laminated Ceramics

- How does a vacuum environment system contribute to the hot pressing sintering of B4C-CeB6? Unlock Peak Ceramic Density

- How does precise temperature control affect FeCoCrNiMnTiC high-entropy alloys? Master Microstructural Evolution

- What is the impact factor of powder metallurgy progress? A 2022 Analysis & Context

- What role does a vacuum hot pressing sintering furnace play for nanocopper? Achieve Maximum Densification Today