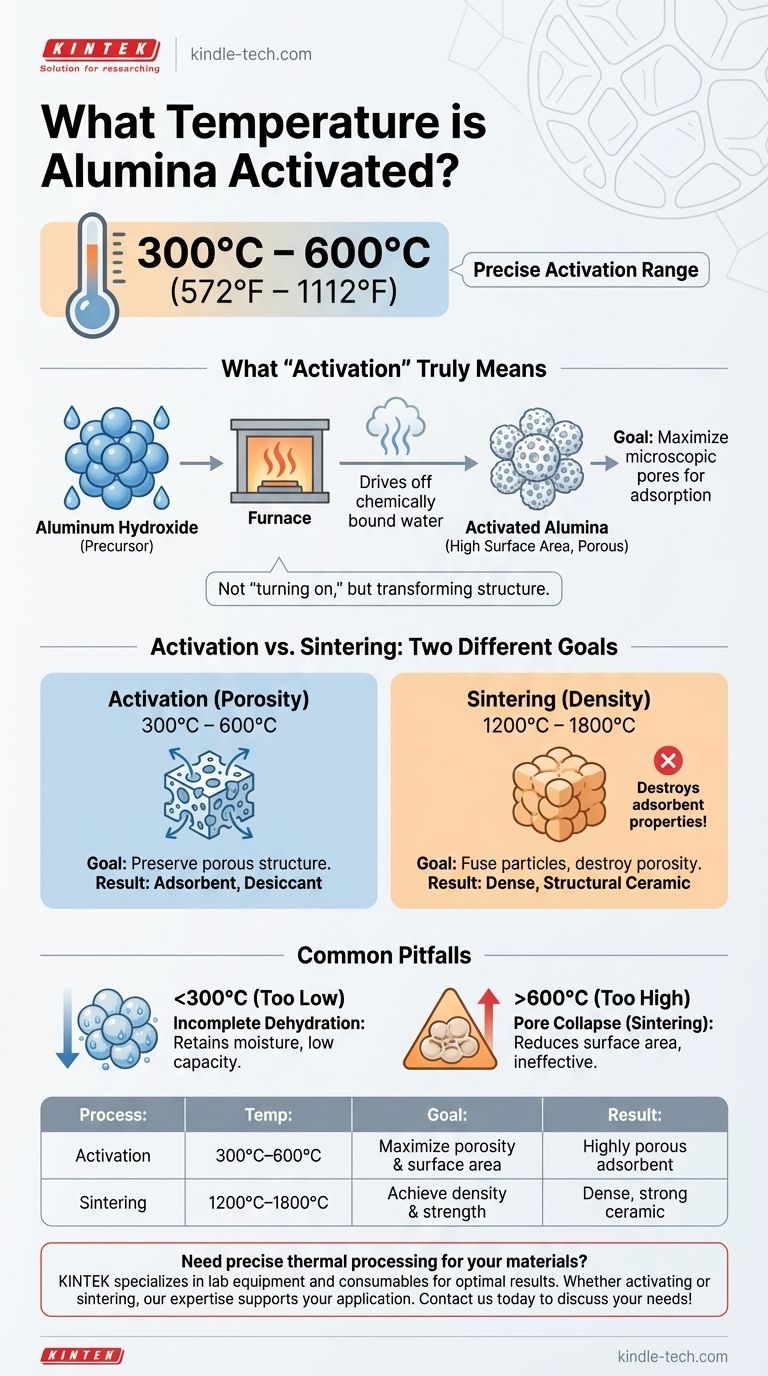

To be precise, alumina is typically activated by heating it to temperatures between 300°C and 600°C (572°F and 1112°F). This specific thermal process is designed to create a highly porous material with a vast internal surface area, making it an excellent adsorbent or catalyst carrier.

The critical concept to grasp is that "activation temperature" and "maximum use temperature" refer to two entirely different processes with opposite goals. Activation creates porosity at lower temperatures, while high-temperature firing creates dense, structural ceramics.

What "Activation" Truly Means for Alumina

The term "activation" can be misleading. It doesn't mean turning the alumina "on." It refers to a specific manufacturing step that transforms aluminum hydroxide into a form of aluminum oxide with unique properties.

The Goal: Maximizing Surface Area

The sole purpose of activation is to create a material with an enormous number of microscopic pores. This network of pores is what gives activated alumina its ability to trap moisture and other substances.

The Mechanism: Driving Off Water

The process starts with a precursor material, typically aluminum hydroxide. Heating it within the activation range drives off chemically bound water molecules.

This water removal leaves behind a rigid, highly porous structure, transforming the material into the familiar white beads of activated alumina used as a desiccant.

Activation vs. Sintering: Two Different Goals

The confusion often arises when comparing the activation temperature with the much higher temperatures alumina can withstand in other applications. These are fundamentally different thermal treatments.

Activation Temperature (300°C – 600°C)

This relatively low temperature range is a carefully controlled balance. It's hot enough to drive off water and form the pore network but cool enough to prevent that network from collapsing.

The goal is to preserve the porous structure and maximize the internal surface area for adsorption.

Sintering/Use Temperature (1200°C – 1800°C)

The extremely high temperatures mentioned for alumina tubes relate to a process called sintering. At these temperatures, the individual alumina particles fuse together.

This process destroys porosity to create a dense, mechanically strong, and chemically resistant ceramic. Heating activated alumina to this range would completely negate its adsorbent properties.

Common Pitfalls to Avoid

Controlling the temperature is the single most important factor in producing effective activated alumina. Deviating from the optimal range has significant consequences.

Heating Too Low (Below 300°C)

If the temperature is too low, the dehydration process will be incomplete. The resulting material will retain moisture, leading to a significantly lower adsorption capacity and poor performance.

Heating Too High (Above 600°C)

Exceeding the activation range causes the pore structure to begin collapsing and fusing, a process known as sintering. This permanently reduces the surface area and destroys the material's ability to act as an effective adsorbent.

Making the Right Choice for Your Goal

The correct thermal treatment for alumina is entirely dependent on your final application.

- If your primary focus is creating a desiccant, adsorbent, or catalyst carrier: You must heat the material within the precise activation range of 300°C to 600°C to maximize its porosity.

- If your primary focus is creating a strong, non-porous, high-temperature ceramic component: You must use a much higher sintering temperature (typically above 1200°C) to achieve full density.

Understanding the distinction between activating for porosity and firing for strength is the key to successfully using alumina in any application.

Summary Table:

| Process | Temperature Range | Primary Goal | Resulting Material Property |

|---|---|---|---|

| Activation | 300°C – 600°C (572°F – 1112°F) | Maximize porosity & surface area | Highly porous adsorbent (e.g., desiccant) |

| Sintering | 1200°C – 1800°C (2192°F – 3272°F) | Achieve density & strength | Dense, strong ceramic (e.g., labware) |

Need precise thermal processing for your materials? KINTEK specializes in lab equipment and consumables, providing the exact heating solutions your laboratory requires. Whether you're activating adsorbents or sintering advanced ceramics, our expertise ensures you achieve optimal results. Contact us today to discuss how we can support your specific application needs!

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Engineering Advanced Fine Ceramics Alumina Al2O3 Crucible With Lid Cylindrical Laboratory Crucible

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Engineering Advanced Fine Alumina Al2O3 Ceramic Crucible for Laboratory Muffle Furnace

- Vacuum Heat Treat and Pressure Sintering Furnace for High Temperature Applications

People Also Ask

- What is the role of polycrystalline alumina (Al2O3) substrates in YSZ thin film preparation? Enhance Film Integrity

- What are the characteristics of SiC? Unlock High-Temp, Hard, and Chemically Inert Performance

- What are the seven classifications of ceramic materials? A Guide to Selecting the Right Material

- Does ceramic break with heat? The Real Culprit is Thermal Shock

- What is the strength of sintered ceramics? Achieve Maximum Density and Durability

- What is another name for ceramic coating? Understanding Nano, Glass, and Quartz Coatings

- What is the ceramic tube high temperature? From 1100°C to 1800°C, Choose the Right Material

- What is the purpose of using an alumina mortar in AlN crystal synthesis? Achieve Molecular Scale Mixing