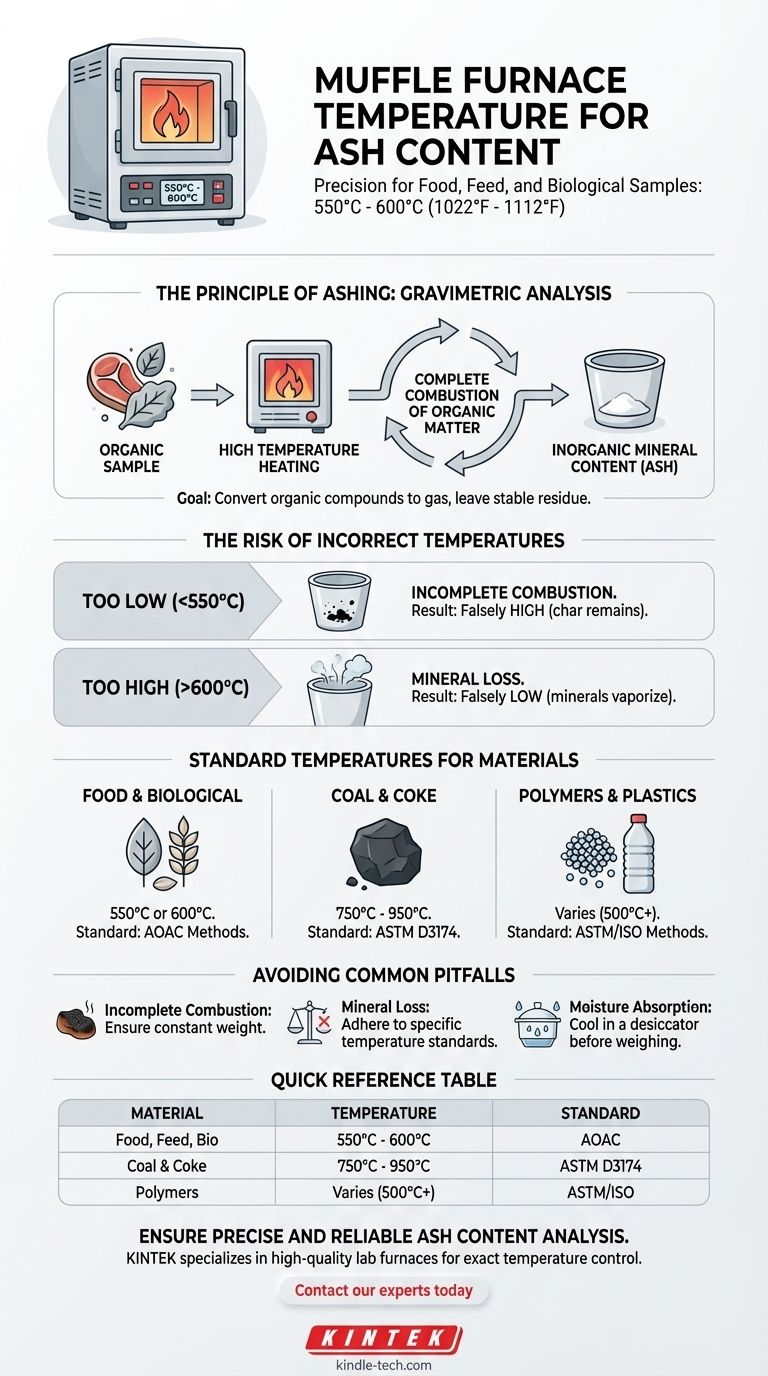

For determining ash content, the most common and widely accepted temperature for a muffle furnace is between 550°C and 600°C (1022°F and 1112°F). This temperature range is a critical standard for most food, feed, and biological samples because it is high enough to ensure complete combustion of organic matter but low enough to prevent the loss of volatile minerals, which would lead to inaccurate results.

The correct ashing temperature is a precise balance. It must be hot enough to completely burn away all organic material, leaving only inorganic ash, but cool enough to prevent that same inorganic ash from decomposing or vaporizing. Your choice of temperature directly dictates the accuracy of your measurement.

The Principle of Ashing: Beyond Just Heat

Ashing is a form of gravimetric analysis where a sample is heated at a high temperature to burn off all organic substances. What remains is the ash, which represents the inorganic, mineral content of the original material.

The Goal: Complete and Clean Combustion

The primary goal is to convert all organic compounds—primarily made of carbon, hydrogen, oxygen, and nitrogen—into gaseous products like carbon dioxide, water vapor, and nitrogen oxides. This leaves behind a stable, non-combustible residue.

The Risk of Incorrect Temperatures

If the temperature is too low, combustion will be incomplete. You will be left with black specks of unburnt carbon, which add weight to the ash and produce a falsely high result.

If the temperature is too high, certain inorganic salts (like chlorides, carbonates, and nitrates) can begin to decompose or volatilize (turn into a gas). This loss of mass from the inorganic portion leads to a falsely low result.

Standard Temperatures for Different Materials

While 550-600°C is a reliable default, the exact temperature is defined by official testing methods for specific materials. Always defer to the standard method if one exists for your sample.

For Food, Feed, and Biological Samples

The Association of Official Analytical Chemists (AOAC) methods almost universally specify 550°C or 600°C. This range has been validated for decades across a vast array of organic products, from grains to processed foods.

For Coal and Coke

Analysis of these materials follows different standards, such as ASTM D3174. These methods often require higher temperatures, typically 750°C, and sometimes a two-stage process with a final temperature of 950°C to ensure all carbon is removed.

For Polymers and Plastics

The ashing temperature for polymers can vary significantly based on the polymer type and its additives. Specific ASTM or ISO methods must be followed, as some materials require gradual temperature ramping to prevent the sample from igniting violently.

Understanding the Trade-offs and Pitfalls

Achieving an accurate ash content reading involves more than just setting the right temperature. The entire procedure is sensitive to error.

Pitfall 1: Incomplete Combustion

The most common error is seeing black particles (char) in your final ash. This means the temperature was too low or the dwell time (the time the sample was held at the target temperature) was too short. The sample must be ashed to a "constant weight," meaning you repeat the heating and weighing process until the mass no longer changes.

Pitfall 2: Mineral Loss

This is a more subtle error. If you use a temperature that is too high for your sample type (e.g., using 750°C for a food sample), you may get a perfectly white ash but the result will be artificially low due to the loss of volatile minerals.

Pitfall 3: Moisture Absorption

Ash is often hygroscopic, meaning it readily absorbs moisture from the air. After heating, the crucible containing the ash must be cooled to room temperature inside a desiccator before weighing. Weighing a hot or moisture-contaminated sample will ruin the measurement.

How to Apply This to Your Analysis

Your approach should be guided by the material you are testing and the standards that govern it.

- If your primary focus is food, feed, or most organic matter: Set your furnace to 550°C. Ensure your sample remains at this temperature for at least 4 hours or until a constant weight is achieved, and always consult the specific AOAC method.

- If your primary focus is coal, polymers, or other industrial materials: Do not guess. You must locate and adhere to the specific ASTM, ISO, or other industry standard for that material, as required temperatures can range from 500°C to over 950°C.

- If you are developing a new method without a standard: Begin with trials at 550°C. Analyze your ash for completeness (no black char). If results seem low, verify by testing at a slightly lower temperature (e.g., 525°C) to see if the mass increases, which would indicate you were losing volatile components at the higher temperature.

Ultimately, precise temperature control is the foundation of a reliable and repeatable ash content analysis.

Summary Table:

| Material Type | Standard Ashing Temperature | Key Standard / Guideline |

|---|---|---|

| Food, Feed, Biological Samples | 550°C - 600°C | AOAC Methods |

| Coal & Coke | 750°C - 950°C | ASTM D3174 |

| Polymers & Plastics | Varies (500°C+); consult specific method | ASTM / ISO Methods |

Ensure precise and reliable ash content analysis in your lab. The correct muffle furnace temperature is critical for accurate results. KINTEK specializes in high-quality lab furnaces and consumables designed for exact temperature control and durability, serving the needs of food, feed, and materials testing laboratories.

Contact our experts today to find the perfect muffle furnace for your specific application and achieve consistent, trustworthy results.

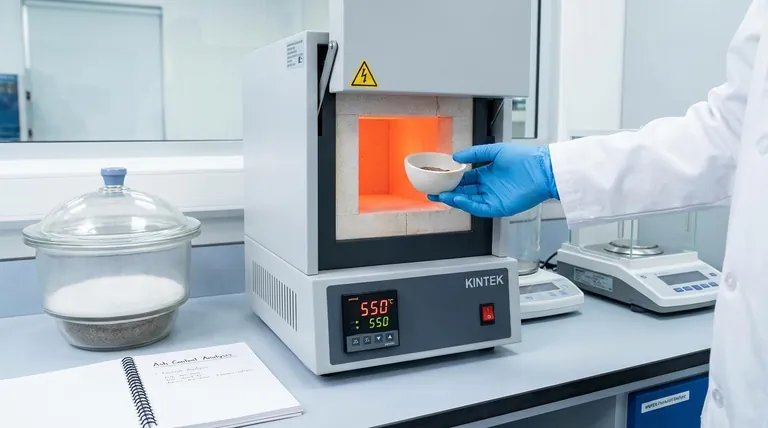

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is a muffle furnace used to estimate? A Key Tool for Precise Ash Determination

- What is the muffle furnace used to estimate? Measure Ash Content and Volatile Matter Precisely

- Is a muffle furnace an oven? A Guide to High-Temperature vs. Low-Temperature Heating

- Why is it called a muffle furnace? The Key to Contamination-Free High-Temperature Heating

- What is the operating temperature of the muffle furnace? Find Your Ideal Range for Lab Success