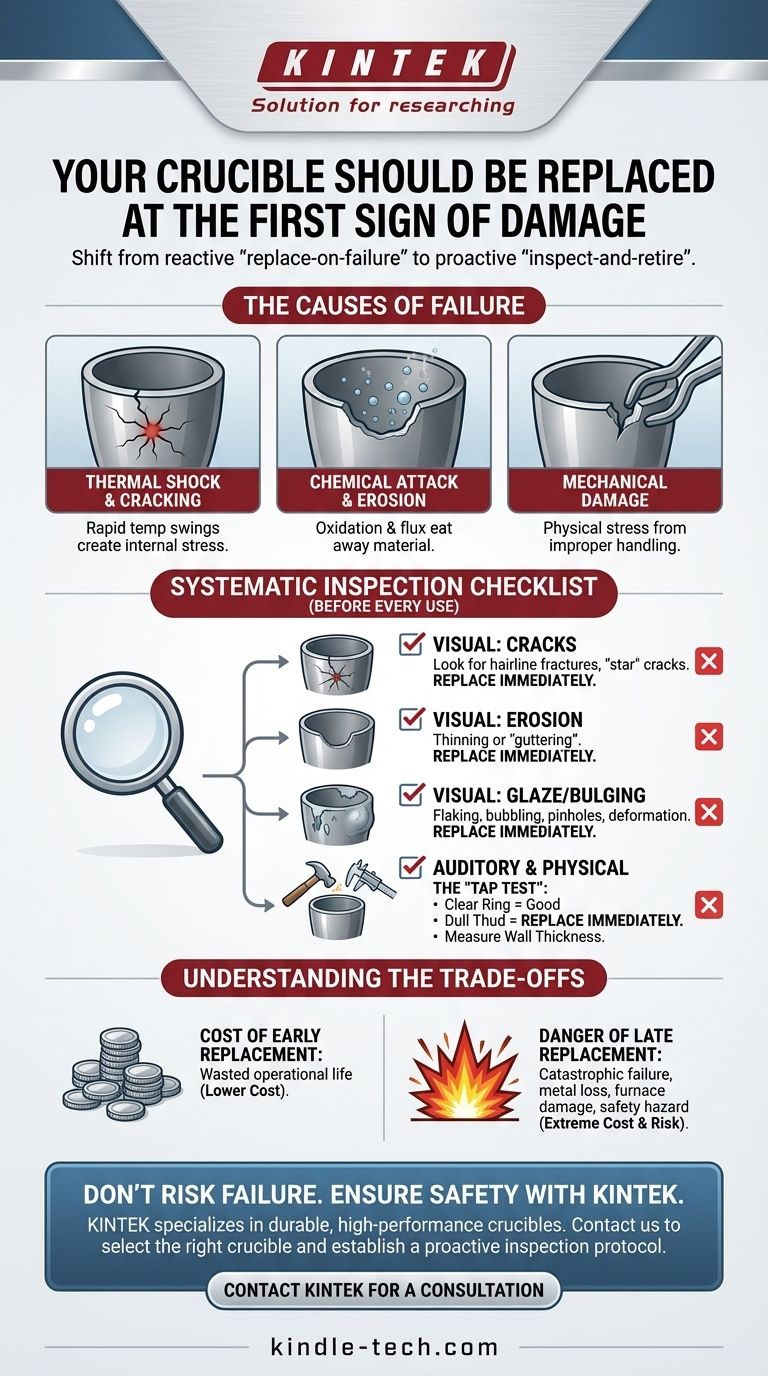

Your crucible should be replaced at the first sign of significant physical damage or after a predetermined number of uses. This is not a component where you should push the limits, as a failure is both dangerous and expensive. Key indicators for replacement include visible cracks, significant erosion of the walls, bulging, or a change in the sound it makes when tapped.

The core principle is shifting from a reactive "replace-on-failure" mindset to a proactive "inspect-and-retire" protocol. A systematic inspection before every use is the most effective strategy to ensure safety, prevent metal loss, and protect your furnace.

The Causes of Crucible Failure

To know when to replace a crucible, you must first understand what wears it down. Failure is rarely sudden; it's the result of cumulative stress and degradation from three primary sources.

Thermal Shock and Cracking

A crucible endures immense temperature swings, expanding on heating and contracting on cooling. If this process happens too quickly, the material cannot expand uniformly, creating internal stress that leads to cracks. This is the most common cause of premature failure.

Chemical Attack and Erosion

At high temperatures, the crucible's surface reacts with oxygen in the air and aggressive fluxes in the melt. This oxidation and chemical erosion slowly eats away at the crucible material, thinning its walls and reducing its structural integrity, particularly at the molten metal line.

Mechanical Damage

Physical stress from improperly fitted tongs, careless charging of heavy ingots, or chipping away slag can cause localized damage. A small chip or gouge can easily become the starting point for a major crack under thermal stress.

A Systematic Inspection Checklist

Perform these checks before every single use. It takes less than a minute and is the best defense against a catastrophic failure.

Visual Inspection: What to Look For

- Cracks: Look for any hairline fractures, both inside and out. Vertical cracks are a major concern, but also inspect the bottom for "star" cracks radiating from the center.

- Erosion or "Guttering": Pay close attention to the area at the typical molten metal line. A visible groove or thinned band here is a serious warning sign.

- Glaze Condition: A healthy silicon carbide crucible will form a green or blackish glaze. This is normal and protective. However, if this glaze is flaking, bubbling, or has pinholes, it indicates the underlying material is degrading.

- Deformation or Bulging: If the crucible walls appear to be bulging outwards, its structural integrity is compromised. It must be retired immediately.

Physical and Auditory Checks

- The "Tap Test": This is a simple but highly effective test. Gently tap the side of the crucible with a wooden or plastic object. A sound crucible will produce a clear, high-pitched ring.

- A Cracked Crucible "Thuds": A crucible with a hidden crack will produce a dull, low-pitched thud. The difference is unmistakable and is an immediate signal to discard the crucible.

- Wall Thickness: For production environments, periodically measuring the wall thickness with calipers provides quantitative data on wear, helping you establish a predictable replacement cycle.

Understanding the Trade-offs

Deciding when to retire a crucible is a balance between cost and safety, but the scales are not evenly weighted.

The Cost of Replacing Too Early

The only downside to replacing a crucible prematurely is the wasted operational life of that unit. This translates directly to a higher cost-per-melt. While this is a valid concern, it pales in comparison to the alternative.

The Danger of Replacing Too Late

The consequences of a crucible failure are severe. They include the complete loss of the molten metal charge, significant damage to your furnace lining and coils, and most importantly, the extreme safety hazard of a large molten metal spill. The financial and physical risk of a failure always outweighs the cost of a new crucible.

Making the Right Choice for Your Foundry

Your approach should be guided by your operational goals and risk tolerance. Use a logbook to track the number of heats on each crucible to establish a baseline lifespan for your specific process.

- If your primary focus is maximum safety (especially for hobbyists): Be extremely conservative and retire a crucible at the first sign of any doubt or visible wear.

- If your primary focus is cost-efficiency in a production environment: Implement a strict logbook and inspection schedule to retire crucibles after a set number of heats, just before they typically begin to show serious wear.

- If you are experiencing frequent or premature failures: The issue is almost certainly your process. Immediately review and improve your preheating, charging, and handling procedures.

By treating your crucible as a critical, inspectable tool rather than a disposable container, you take direct control over the safety and efficiency of your entire melting operation.

Summary Table:

| Inspection Check | What to Look For | Action |

|---|---|---|

| Visual: Cracks | Hairline or star cracks inside/outside | Replace Immediately |

| Visual: Erosion | Thinning or 'guttering' at the metal line | Replace Immediately |

| Visual: Glaze | Flaking, bubbling, or pinholes in the glaze | Replace Immediately |

| Auditory: Tap Test | Dull thud instead of a clear ring | Replace Immediately |

| Physical: Bulging | Walls deforming outwards | Replace Immediately |

Don't risk a dangerous crucible failure. KINTEK specializes in high-performance lab equipment and consumables, including durable crucibles designed for safety and longevity. Our experts can help you select the right crucible for your specific melting process and establish a proactive inspection protocol to protect your furnace and personnel.

Contact KINTELK today for a consultation and ensure your melting operations are safe and efficient.

Visual Guide

Related Products

- Arc-Shaped Alumina Ceramic Crucible High Temperature Resistant for Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Ceramics Alumina Crucibles (Al2O3) for Thermal Analysis TGA DTA

- Engineering Advanced Fine Ceramics Alumina Al2O3 Crucible With Lid Cylindrical Laboratory Crucible

- Alumina Al2O3 Ceramic Crucible Semicircle Boat with Lid for Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Alumina Al2O3 Ceramic Crucible for Laboratory Muffle Furnace

People Also Ask

- Why is an alumina crucible used for pre-calcination of LAGP? Ensure High-Purity Solid-State Synthesis

- What role does a sapphire crucible play in high-temperature molten salt experiments? Ensure Purity & Data Integrity

- How does the choice between graphite and metal-lined crucibles affect molten salt corrosion? Find the Right Research Tool

- How does the use of corrosion-resistant ceramic crucibles ensure the chemical purity of materials? | KINTEK

- What is the protective function of high-purity ceramic crucibles? Secure the Chemical Integrity of Your SA508 Alloys

- What can I use as a crucible for melting gold? Choose the Right Material for a Clean, Efficient Melt

- What is the temperature range of a carbon crucible? Maximize Performance with the Right Atmosphere

- Can you melt gold in a ceramic crucible? Discover the Right Crucible for Safe Melting