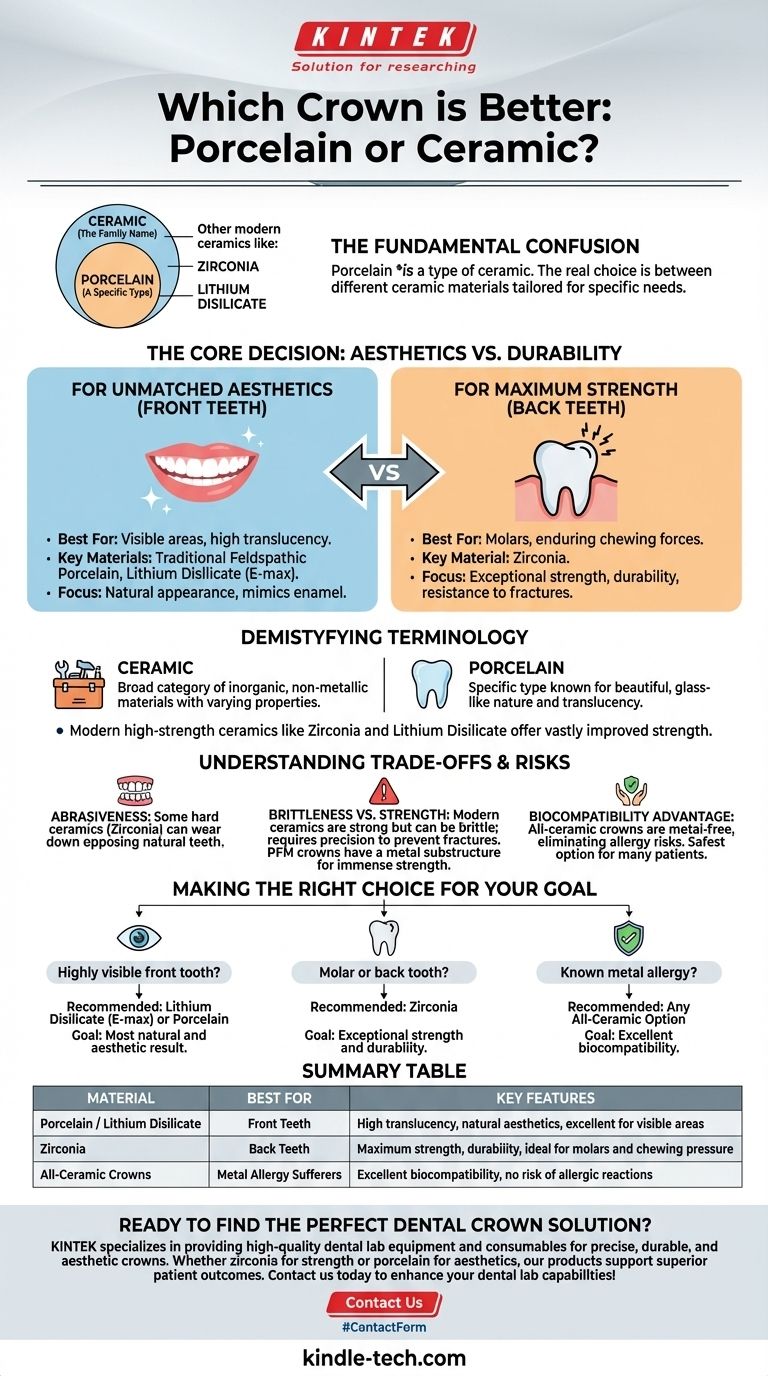

The fundamental confusion is that porcelain is a type of ceramic. When people ask this question, they are trying to understand the difference between various types of all-ceramic dental crowns available today. The real choice is not between "porcelain" and "ceramic," but between different ceramic materials tailored for specific needs.

The "better" crown depends entirely on the location of the tooth. Highly aesthetic, translucent ceramics are best for visible front teeth, while incredibly strong, more opaque ceramics are superior for back teeth that handle immense chewing pressure.

Demystifying the Terminology

The terms "porcelain" and "ceramic" are often used interchangeably in dentistry, which creates confusion. Understanding the distinction is the first step in making an informed decision.

What "Ceramic" Means in Dentistry

In dentistry, ceramic refers to a broad category of inorganic, non-metallic materials. Think of it as a family name that includes many different materials with varying properties of strength, translucency, and durability.

Where "Porcelain" Fits In

Porcelain is a specific type of ceramic. Traditional dental porcelain is known for its beautiful, glass-like nature, which allows it to mimic the translucency and color of a natural tooth with exceptional accuracy.

The Modern High-Strength Ceramics

Decades ago, porcelain was the primary all-ceramic option. Today, dentistry benefits from advanced ceramics like zirconia and lithium disilicate, which offer vastly improved strength while maintaining excellent aesthetics.

The Core Decision: Aesthetics vs. Durability

Your choice of crown material hinges on a critical trade-off: achieving the most natural appearance versus ensuring the highest possible strength. The location of your tooth dictates which factor is more important.

For Unmatched Aesthetics (Front Teeth)

Materials like traditional feldspathic porcelain and lithium disilicate (E-max) are the gold standard for front teeth. Their high translucency allows light to pass through them similarly to natural tooth enamel, resulting in a seamless, lifelike appearance.

For Maximum Strength (Back Teeth)

For molars, which endure tremendous grinding and chewing forces, zirconia is often the ideal choice. It is an exceptionally strong and durable ceramic that is highly resistant to chipping and fractures, prioritizing function and longevity over perfect translucency.

Understanding the Trade-offs and Risks

While all-ceramic crowns offer significant advantages, particularly for those with metal allergies, it's crucial to understand their potential downsides.

Abrasiveness to Opposing Teeth

Some of the hardest ceramics, particularly certain types of zirconia, can be more abrasive than natural enamel. Over time, this can cause wear on the opposing natural teeth, a factor your dentist will carefully consider.

Brittleness vs. Strength

While modern ceramics are very strong, they can be more brittle than traditional porcelain-fused-to-metal (PFM) crowns. A PFM crown has a metal substructure that provides immense strength, though the porcelain layer on top can still chip. All-ceramic crowns eliminate metal but must be handled with precision by the lab and dentist to prevent fractures.

The Biocompatibility Advantage

A major benefit of any all-ceramic crown is its excellent biocompatibility. Since there is no metal, the risk of allergic reactions or sensitivity is virtually eliminated, making it the safest option for many patients.

Making the Right Choice for Your Goal

Consulting with your dentist is paramount, but understanding these materials allows you to be an active partner in your own care.

- If your primary focus is a highly visible front tooth: Your best options are likely lithium disilicate (E-max) or traditional porcelain for the most natural and aesthetic result.

- If your primary focus is a molar or back tooth: Zirconia is the superior choice for its exceptional strength and durability under heavy chewing forces.

- If you have a known metal allergy or sensitivity: Any all-ceramic option is the safest and most appropriate choice to ensure excellent biocompatibility.

Ultimately, knowing the difference between these advanced materials empowers you to have a more productive conversation with your dentist about your specific clinical needs.

Summary Table:

| Material | Best For | Key Features |

|---|---|---|

| Porcelain / Lithium Disilicate | Front Teeth | High translucency, natural aesthetics, excellent for visible areas |

| Zirconia | Back Teeth | Maximum strength, durability, ideal for molars and chewing pressure |

| All-Ceramic Crowns | Metal Allergy Sufferers | Excellent biocompatibility, no risk of allergic reactions |

Ready to find the perfect dental crown solution for your needs? At KINTEK, we specialize in providing high-quality dental lab equipment and consumables that help create precise, durable, and aesthetically pleasing crowns. Whether you're a dental lab focusing on zirconia for strength or porcelain for aesthetics, our products support your work in delivering superior patient outcomes. Contact us today to learn how KINTEK can enhance your dental lab capabilities and ensure you have the right tools for every case!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Dental Porcelain Sintering Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What are the components of dental porcelain? A Guide to Engineered Strength and Beauty

- What are the failures of zirconia? Avoid Fracture and Debonding with Proper Protocol

- What are the advantages of zirconia bridges? A Durable, Metal-Free Solution for a Natural Smile

- What is sintering in dentistry? Transform Zirconia into High-Strength Dental Restorations

- Do ceramic crowns look natural? Achieve a Seamless, Natural-Looking Smile

- What are the different types of ceramics in dentistry? Choose the Right Material for Strength & Aesthetics

- How long does it take to sinter zirconia? A Guide to Optimizing Your Sintering Cycle

- How long does it take to make zirconia teeth? From Same-Day to 2 Weeks