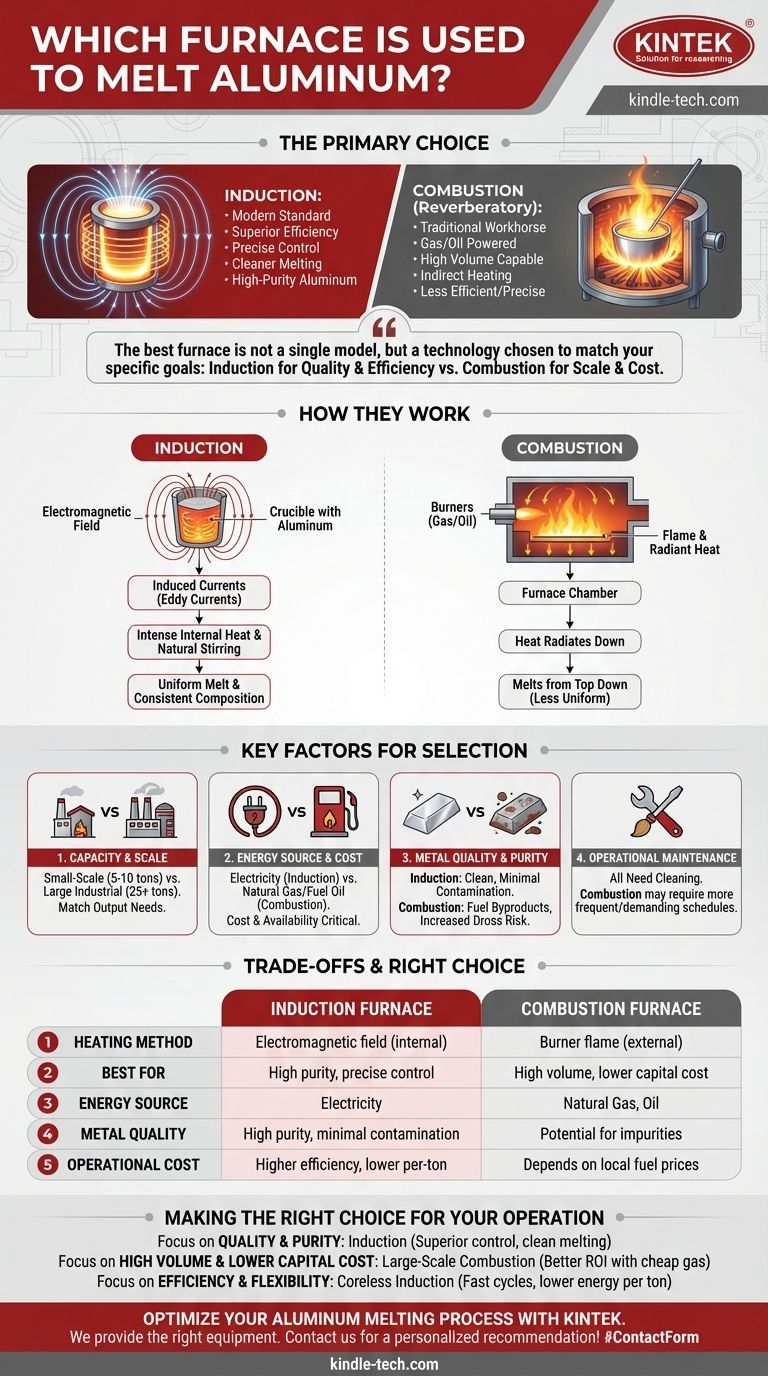

For melting aluminum, the primary choice in modern industrial applications is the induction furnace. This technology uses an electromagnetic field to generate heat directly within the metal, offering superior energy efficiency, precise temperature control, and a cleaner melting process compared to traditional methods. While other furnaces, such as those using gas or oil for combustion, are also used, induction technology is often preferred for applications requiring high-purity aluminum.

The best furnace for melting aluminum is not a single model, but a technology chosen to match your specific goals. While induction furnaces offer the highest quality and efficiency, the decision ultimately balances production scale, energy costs, and required metal purity.

The Principal Furnace Types for Aluminum

Understanding the core technologies is the first step. For aluminum, the choice generally comes down to two distinct methods of generating heat: internal (induction) or external (combustion).

Induction Furnaces: The Modern Standard

An induction furnace works by passing a powerful alternating current through a coil that surrounds a crucible containing the aluminum. This creates a strong electromagnetic field that induces electrical currents (eddy currents) within the metal itself, generating intense heat from the inside out.

This process is analogous to how a microwave heats food, but far more powerful and targeted. The electromagnetic forces also create a natural stirring action, ensuring a uniform temperature and consistent chemical composition throughout the molten bath.

Combustion Furnaces: The Traditional Workhorse

Combustion furnaces, often called reverberatory furnaces, operate more like a conventional oven. They use burners powered by natural gas, oil, or diesel to generate a flame that heats the chamber's ceiling and walls.

This heat then radiates down onto the aluminum, melting it from the top down. While effective and capable of handling very large volumes, this indirect heating method is less efficient and offers less precise temperature control than induction.

Key Factors Driving Your Furnace Selection

The "best" furnace is the one that best aligns with your operational priorities. Four factors are critical to your decision.

Melting Capacity and Production Scale

Your required output dictates the necessary furnace size. Small-scale operations or foundries might use furnaces with a 5-10 ton capacity. In contrast, large industrial plants often require furnaces of 25 tons or more to achieve cost-effective production at scale.

Energy Source and Cost

The most significant operational cost is energy. Induction furnaces run on electricity, while combustion furnaces typically use natural gas or fuel oil. Your choice will heavily depend on the local cost and availability of these energy sources.

Metal Quality and Purity

This is where the technologies diverge significantly. Because induction heats the metal directly and cleanly, there is minimal risk of contamination. Combustion furnaces expose the molten aluminum to the byproducts of burning fuel, which can introduce impurities and increase the formation of dross (oxide waste).

Operational Maintenance

All furnaces require cleaning to remove dross, which insulates the melt and reduces efficiency. However, the higher potential for oxidation in combustion furnaces can lead to more frequent and demanding maintenance schedules to maintain optimal performance.

Understanding the Trade-offs: Induction vs. Combustion

Neither technology is universally superior; each comes with clear advantages and disadvantages.

Why Choose an Induction Furnace?

The primary drivers for choosing induction are quality and efficiency. They provide faster, cleaner melting with precise temperature control, resulting in higher-quality, purer aluminum. The strong stirring action also guarantees a homogenous mixture, which is critical for producing high-specification alloys.

When Might a Combustion Furnace Be Better?

A combustion furnace may be the right choice when initial capital cost and sheer volume are the top priorities. These systems are often less expensive to purchase and can be built to massive scales for continuous, high-tonnage melting. They are a viable workhorse if you have access to cheap fossil fuels and your application can tolerate minor variations in metal chemistry.

Making the Right Choice for Your Operation

Your decision should be guided by your most critical operational priority.

- If your primary focus is maximum metal quality and purity: An induction furnace is the superior choice due to its clean melting and precise temperature control.

- If your primary focus is high-volume production at the lowest capital cost: A large-scale combustion furnace may offer a better return on investment, especially if you have access to cheap natural gas.

- If your primary focus is energy efficiency and operational flexibility: A coreless induction furnace provides fast melting cycles and lower energy consumption per ton, ideal for varied batch work.

By aligning the furnace technology with your specific production goals, you ensure an investment that is not just functional, but optimal.

Summary Table:

| Feature | Induction Furnace | Combustion Furnace |

|---|---|---|

| Heating Method | Electromagnetic field (internal) | Burner flame (external) |

| Best For | High purity, precise control | High volume, lower capital cost |

| Energy Source | Electricity | Natural Gas, Oil |

| Metal Quality | High purity, minimal contamination | Potential for impurities |

| Operational Cost | Higher efficiency, lower per-ton energy | Depends on local fuel prices |

Ready to optimize your aluminum melting process?

At KINTEK, we specialize in providing the right lab and industrial equipment for your specific needs. Whether you require the high purity of an induction furnace or the high-volume capacity of a combustion system, our experts can help you select the perfect solution to enhance efficiency, control costs, and ensure superior metal quality.

Contact us today to discuss your project and get a personalized recommendation!

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- Vertical Laboratory Tube Furnace

People Also Ask

- What is the temperature of a melting furnace? A Guide to Material-Specific Heat Ranges

- How is induction heating used in industry and consumer products? Achieve Fast, Clean, and Precise Heating

- What is the difference between coreless and cored induction furnace? Choose the Right Tool for Your Foundry

- How can I increase the efficiency of my induction furnace? A Holistic Guide to Lower Costs & Higher Output

- How does a vacuum resistance melting furnace prevent magnesium oxidation? Protect AM60 Alloy Purity

- What is the difference between induction melting and vacuum induction melting? Choosing the Right Process for Purity

- What is the advantage of induction furnace? Achieve Clean, Precise, and Efficient Metal Melting

- What is the temperature range of induction heating? From Gentle Warming to Extreme Melting