When choosing a dental crown, the "better" option depends entirely on the tooth's location and your personal priorities. All-ceramic crowns offer superior, natural-looking aesthetics, making them the definitive choice for front teeth. Metal crowns, by contrast, provide unparalleled strength and durability, making them an excellent, long-lasting solution for back molars where chewing forces are greatest.

Your decision is not a simple choice of one material over another. It is a strategic trade-off between the visible aesthetics required for your smile and the functional durability required for chewing.

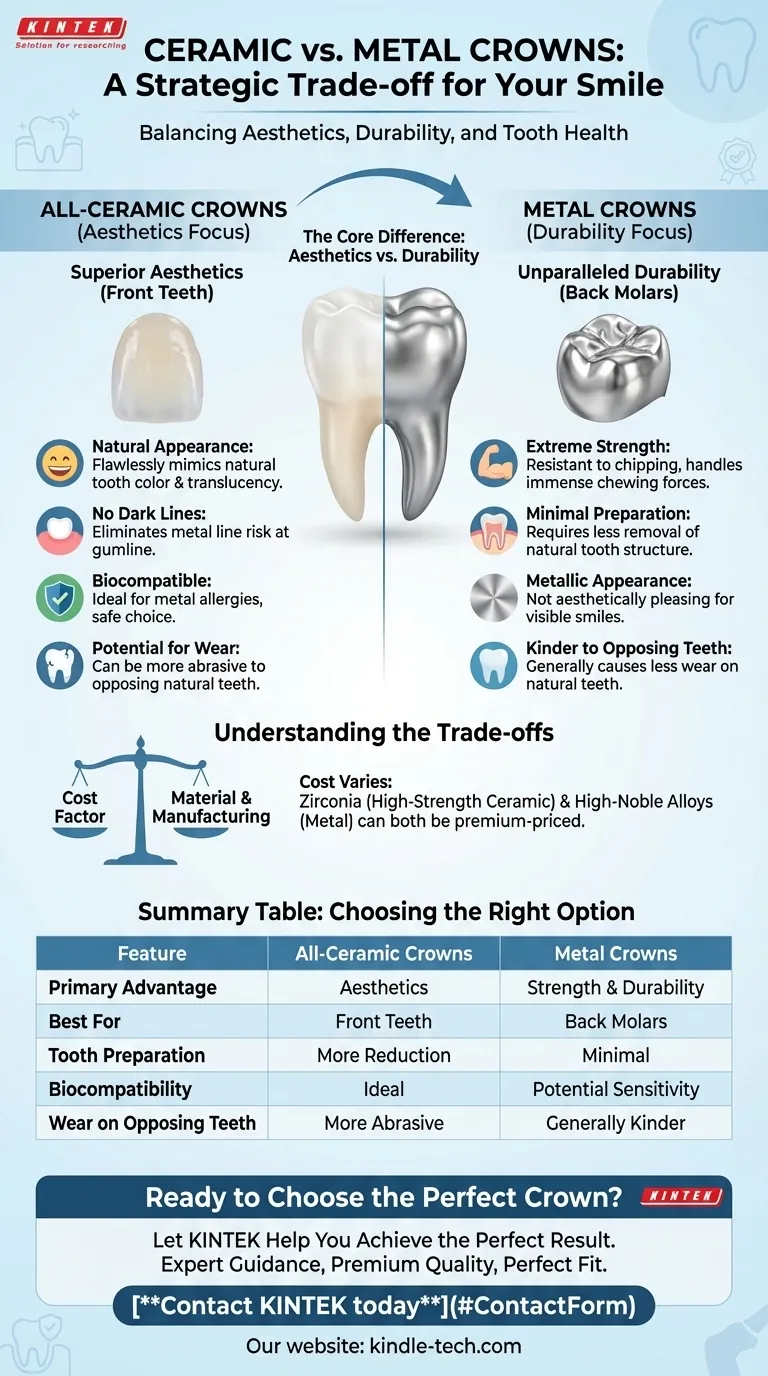

The Core Difference: Aesthetics vs. Durability

The fundamental choice between ceramic and metal crowns hinges on balancing how the tooth looks with how much force it needs to withstand.

All-Ceramic Crowns: The Aesthetic Standard

Modern all-ceramic crowns, particularly those made from materials like zirconia, are designed to flawlessly mimic the appearance of a natural tooth.

They have a homogenous, tooth-like color and translucency. This eliminates the risk of a dark metal line appearing at the gumline, a potential issue with older porcelain-fused-to-metal crowns.

Because of their excellent aesthetics, all-ceramic crowns are the preferred option for restoring highly visible teeth, especially in the front of the mouth.

Metal Crowns: The Durability Benchmark

Metal crowns are exceptionally strong and resistant to chipping or breaking. They can withstand immense chewing and grinding forces over many years.

This durability makes them an ideal choice for molars in the back of the mouth, which are not easily visible but do the majority of the heavy work in chewing.

The obvious downside is their metallic appearance, which does not blend in with natural teeth and is considered aesthetically poor for any visible part of a smile.

Impact on Your Natural Tooth and Health

Beyond the primary factors of looks and strength, the material choice has other important implications for your long-term dental health.

Tooth Preparation Requirements

A significant advantage of metal crowns is that they often require minimal tooth preparation. Because the material is so strong, the crown can be made thinner.

This means your dentist needs to remove less of your natural tooth structure to fit the crown, which is always the preferred clinical goal.

Biocompatibility and Allergies

All-ceramic crowns are an excellent solution for individuals with known metal allergies. They are highly biocompatible and eliminate any risk of an allergic reaction.

While rare, some patients can have sensitivities to the alloys used in metal crowns, making ceramic the safer choice in those cases.

Understanding the Trade-offs

A trusted decision requires acknowledging the potential downsides and costs associated with each option.

The Cost Factor

The price of a crown can vary significantly based on material and manufacturing.

High-strength ceramics like zirconia are often more expensive due to the advanced material and milling processes required to produce them.

Conversely, some metal crowns, especially those made from high-noble alloys like gold, can also be a premium-priced option. The cost is highly dependent on the specific materials used.

Potential for Wear on Other Teeth

While incredibly strong, some high-strength ceramic materials can be more abrasive than natural enamel.

This means an all-ceramic crown, particularly on a back tooth, may cause slightly accelerated wear on the opposing natural tooth it bites against. Metal, by contrast, tends to be kinder to opposing teeth.

Making the Right Choice for Your Tooth

Consult with your dentist, but use these principles to guide your decision based on the specific goal for the tooth being restored.

- If your primary focus is aesthetics (a front tooth): An all-ceramic crown is the clear choice for a natural, seamless look.

- If your primary focus is maximum durability (a back molar): A metal crown offers a time-tested, robust, and long-lasting solution.

- If you have a known metal allergy or sensitivity: An all-ceramic crown is the only appropriate and safe option.

- If you want to preserve the most natural tooth structure: A metal crown may be preferable due to the minimal preparation required.

Ultimately, the best crown is the one that correctly aligns the material's properties with the specific functional and aesthetic demands of your tooth.

Summary Table:

| Feature | All-Ceramic Crowns | Metal Crowns |

|---|---|---|

| Primary Advantage | Superior, natural aesthetics | Unmatched strength & durability |

| Best For | Front teeth (high visibility) | Back molars (high chewing force) |

| Tooth Preparation | Requires more tooth reduction | Minimal tooth preparation |

| Biocompatibility | Ideal for metal allergies | Potential for rare metal sensitivities |

| Wear on Opposing Teeth | Can be more abrasive | Generally kinder to natural teeth |

Ready to Choose the Perfect Crown for Your Smile?

This guide has outlined the critical trade-offs between aesthetics and durability. Making the right choice is essential for your long-term oral health and confidence.

Let KINTEK Help You Achieve the Perfect Result.

As a leading dental lab, we specialize in crafting high-quality, custom dental crowns that meet your specific needs. Whether your priority is the flawless aesthetics of a ceramic crown for a front tooth or the proven durability of a metal crown for a molar, our experts use premium materials and precise techniques to ensure a perfect fit and long-lasting performance.

We provide:

- Expert Guidance: Help in selecting the ideal material for your specific case.

- Premium Quality: Durable metal crowns and aesthetically superior ceramic crowns (including zirconia).

- Perfect Fit: Custom-crafted restorations for optimal comfort and function.

Don't leave your smile to chance. Consult with your dentist and partner with a lab that prioritizes quality.

Contact KINTEK today to discuss your crown needs and learn how we can support your dental practice in delivering the best possible outcomes for your patients.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- Vertical Laboratory Tube Furnace

People Also Ask

- What is the price of zirconia sintering furnace? Invest in Precision, Not Just a Price Tag

- What is the effect of zirconia sintering temperature? Master the Key to Strength and Stability

- What is the sintering temperature of zirconium? A Guide to the 1400°C-1600°C Range for Dental Labs

- Can you change the color of zirconia crowns? Understanding the Permanent Nature of Zirconia

- What are the white spots on zirconia after sintering? A Guide to Diagnosing and Preventing Defects