Of all pure metals, tungsten (W) is the hardest to melt. It has an astonishingly high melting point of 3422°C (6192°F), a temperature at which most other metals have long since vaporized. This exceptional resistance to heat is due to the incredibly strong metallic bonds holding its atoms together.

The difficulty in melting a metal is a direct measure of the energy required to break the bonds holding its atomic structure together. While tungsten holds the title for pure metals, the true frontier of heat resistance lies in engineered alloys and ceramics, which can withstand even more extreme temperatures.

What Determines a Metal's Melting Point?

The melting point is not an arbitrary number; it's a fundamental property dictated by physics at the atomic level. Understanding this principle is more important than memorizing a single fact.

The Strength of Atomic Bonds

Metals in their solid state are arranged in a rigid, ordered crystalline lattice. Melting is the physical process of supplying enough thermal energy (heat) to overcome the forces holding this lattice together, allowing the atoms to move more freely as a liquid.

Key Factors in Bond Strength

The strength of these metallic bonds depends on factors like the atom's size, its number of valence electrons (the outer electrons involved in bonding), and how densely the atoms are packed. Metals like tungsten have a large number of valence electrons that are shared among many atoms, creating an extremely strong and stable structure that requires immense energy to disrupt.

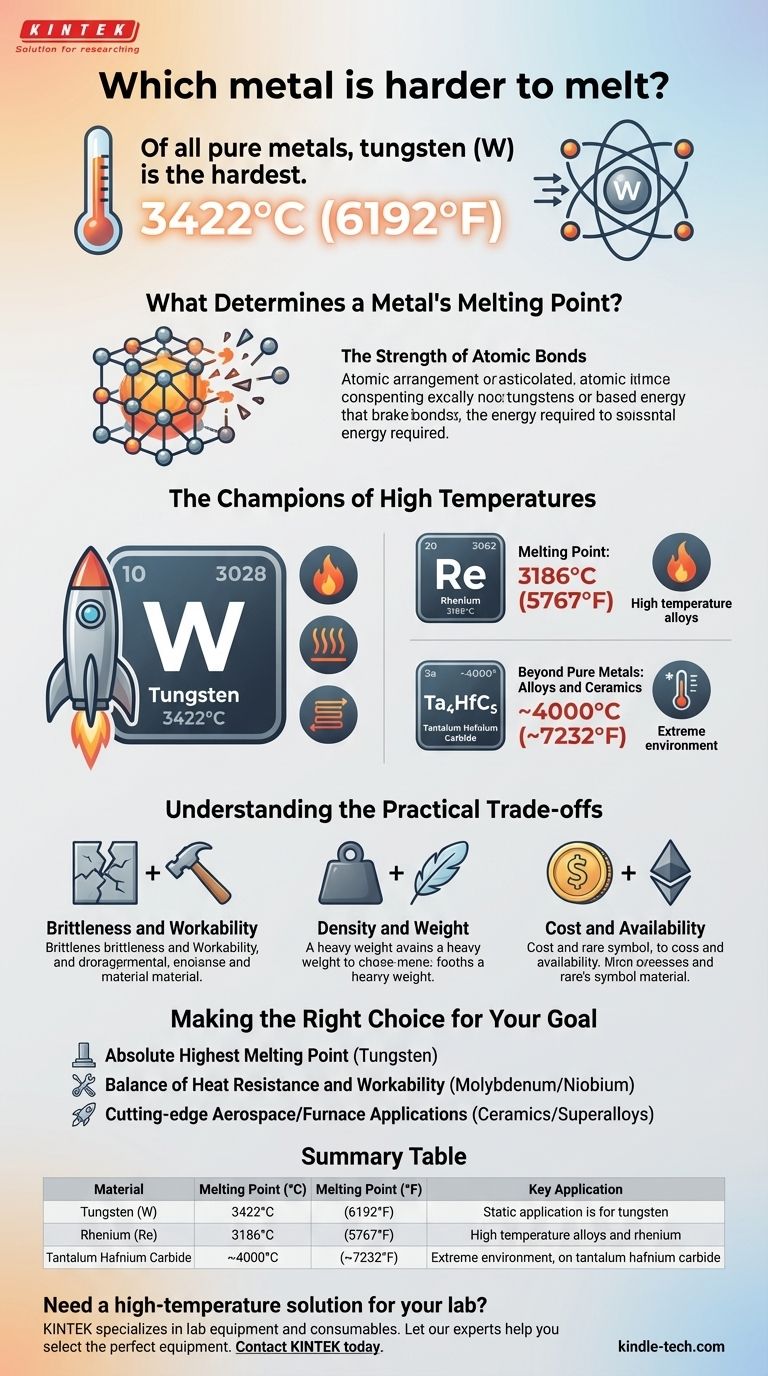

The Champions of High Temperatures

While tungsten is the winner among pure elements, it's helpful to see how it compares to others and what lies beyond the world of pure metals.

The Pure Metal King: Tungsten (W)

With a melting point of 3422°C (6192°F), tungsten stands alone. This is why it was historically used for the filaments in incandescent light bulbs, which needed to glow white-hot without melting. Today, it's critical for applications like rocket nozzles, welding electrodes, and heating elements in high-temperature furnaces.

The Runner-Up: Rhenium (Re)

The second-highest melting point for a pure metal belongs to Rhenium, which melts at 3186°C (5767°F). It is often alloyed with other high-temperature metals like tungsten and molybdenum to improve their properties, particularly ductility.

Beyond Pure Metals: Alloys and Ceramics

Engineers often create materials with even higher performance than their constituent elements. Refractory alloys and ceramics are designed specifically for extreme heat. For example, Tantalum Hafnium Carbide (Ta₄HfC₅) is a ceramic compound with one of the highest known melting points, near 4000°C (7232°F).

Understanding the Practical Trade-offs

Choosing a material based solely on melting point is a common mistake. The metals most resistant to heat often come with significant disadvantages that limit their use.

Brittleness and Workability

Metals with extremely high melting points, like tungsten, tend to be very brittle and hard at room temperature. This makes them incredibly difficult to machine, form, or shape, which adds significant cost and complexity to manufacturing.

Density and Weight

These elements are also among the densest materials on earth. Tungsten's density is nearly identical to gold and almost twice that of lead. This immense weight makes it unsuitable for applications where weight is a critical factor, such as in most aerospace components.

Cost and Availability

Elements like Rhenium are exceptionally rare and, therefore, extremely expensive. Their cost restricts their use to only the most critical and high-performance applications where no other material will suffice.

Making the Right Choice for Your Goal

The "best" material depends entirely on the specific problem you are trying to solve. Consider the balance of properties required for your application.

- If your primary focus is the absolute highest melting point for a pure element: Tungsten is the definitive choice, ideal for static, high-temperature components like filaments and electrodes.

- If you need a balance of heat resistance and better workability: Consider metals like molybdenum (melting point 2623°C) or niobium (2477°C), which offer excellent performance without tungsten's extreme brittleness.

- If you are designing for cutting-edge aerospace or furnace applications: You must look beyond pure metals to engineered ceramics and superalloys designed for a specific combination of heat resistance, strength, and weight.

Understanding that a high melting point is just one property among many is the key to effective and intelligent material selection.

Summary Table:

| Material | Melting Point (°C) | Melting Point (°F) | Key Application |

|---|---|---|---|

| Tungsten (W) | 3422°C | 6192°F | Rocket nozzles, heating elements |

| Rhenium (Re) | 3186°C | 5767°F | High-temperature alloys |

| Tantalum Hafnium Carbide (Ceramic) | ~4000°C | ~7232°F | Extreme environment applications |

Need a high-temperature solution for your lab?

Choosing the right material is critical for the success and safety of your high-temperature processes. KINTEK specializes in lab equipment and consumables, including high-temperature furnaces and components designed for materials like tungsten and advanced ceramics.

Let our experts help you select the perfect equipment for your specific application, balancing heat resistance, workability, and cost.

Contact KINTEK today for a consultation and enhance your lab's capabilities!

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Muffle Oven Furnace for Laboratory

People Also Ask

- Why is a quartz tube furnace utilized in the thermal oxidation of MnCr2O4 coatings? Unlock Precise Selective Oxidation

- What materials are used for the tubes in tube furnaces? A Guide to Selecting the Right Tube for Your Process

- How to clean a tube furnace? A Step-by-Step Guide for Safe and Effective Maintenance

- What is a tubular furnace used for? Precision Heating for Material Synthesis & Analysis

- How does a quartz tube vacuum furnace contribute to the crystallization process of Ag-doped Li-argyrodite electrolytes?