At its core, pyrolysis is chosen because it is a powerful technology for converting organic waste into valuable resources. Instead of simply disposing of materials like plastics, rubber, or biomass in a landfill, pyrolysis uses high heat in an oxygen-free environment to chemically decompose them into biofuels, chemicals, and other recoverable materials.

Pyrolysis is more than a waste management technique; it is a resource transformation process. It re-frames waste as a valuable feedstock for creating new products, directly supporting circular economy principles and providing alternatives to fossil fuels.

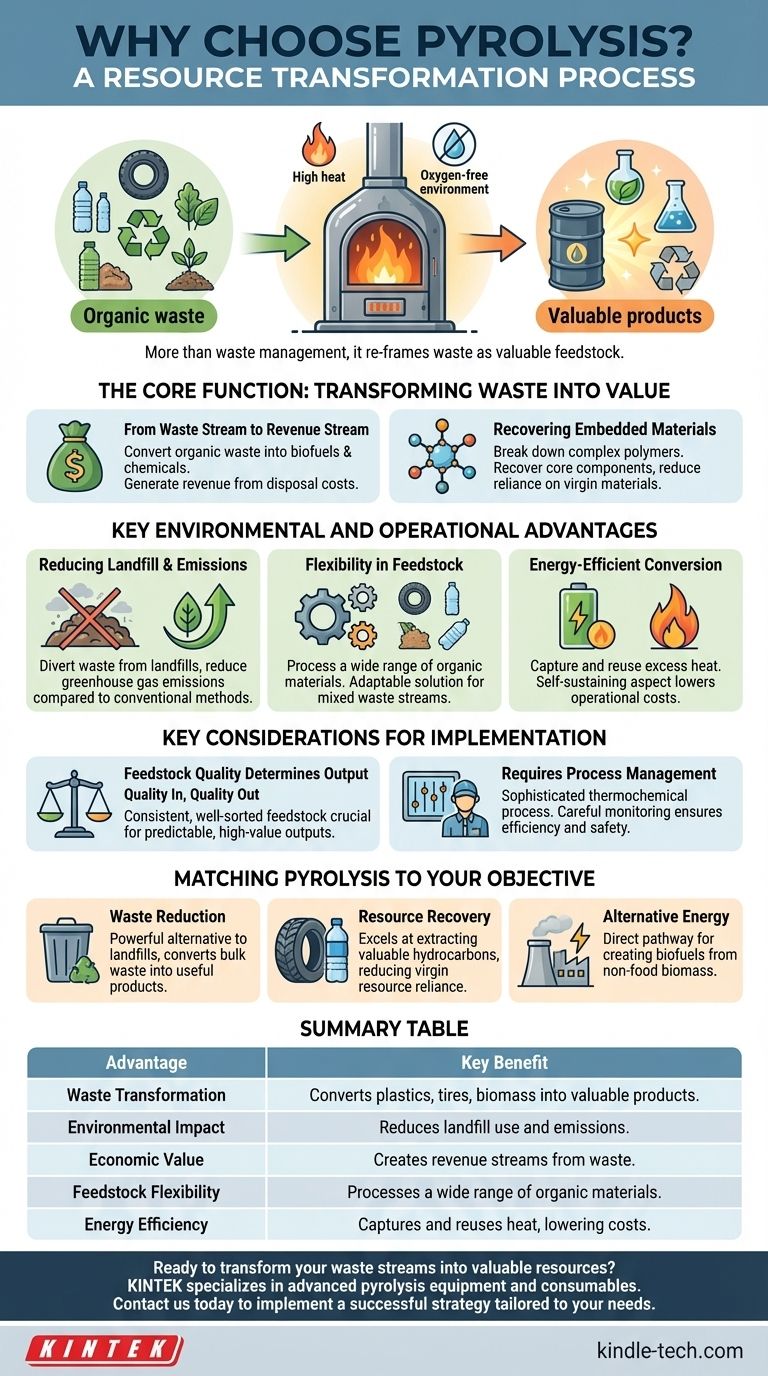

The Core Function: Transforming Waste into Value

Pyrolysis fundamentally changes the equation for waste management. It is an active conversion process, not a passive disposal method.

From Waste Stream to Revenue Stream

The primary output of pyrolysis is a set of valuable products. Organic waste materials are converted into biofuels and industrial chemicals.

This creates a direct pathway to generate revenue from materials that would otherwise represent a disposal cost.

Recovering Embedded Materials

Many waste streams, particularly plastics and tires, contain valuable hydrocarbons. Pyrolysis is exceptionally effective at breaking down these complex polymers.

This process enables the recovery of these core components, reducing the environmental impact and economic cost associated with sourcing virgin raw materials.

Key Environmental and Operational Advantages

Beyond the value of its outputs, pyrolysis presents a compelling case based on its environmental benefits and operational flexibility.

Reducing Landfill and Emissions

By diverting significant volumes of waste from landfills, pyrolysis directly addresses a major environmental challenge.

This process also helps reduce greenhouse gas emissions when compared to conventional disposal methods or the production of new materials from fossil fuels.

Flexibility in Feedstock

A key operational advantage is the furnace's flexibility. Pyrolysis can effectively process a wide range of different organic materials.

This versatility makes it an adaptable solution for various industries and municipalities that deal with mixed or changing waste streams.

Energy-Efficient Conversion

The process itself is designed for energy efficiency. Modern pyrolysis systems often capture and reuse excess heat generated during the thermal decomposition.

This self-sustaining aspect can lower operational costs and further improve the overall environmental footprint of the technology.

Key Considerations for Implementation

While powerful, choosing pyrolysis requires understanding its operational context. The process is not a simple "plug-and-play" solution and demands a strategic approach.

Feedstock Quality Determines Output

The principle of "quality in, quality out" applies directly to pyrolysis. The specific composition of the waste material being processed will directly influence the type and quality of the resulting biofuels and chemicals.

Consistent and well-sorted feedstock is crucial for achieving predictable and high-value outputs.

Requires Process Management

As a sophisticated thermochemical process, pyrolysis requires careful monitoring and management to ensure optimal efficiency and safety.

Achieving the stated benefits depends on well-maintained equipment and knowledgeable operators who can adapt the process to different materials.

Matching Pyrolysis to Your Objective

To determine if pyrolysis is the right choice, align the technology's core strengths with your primary goal.

- If your primary focus is waste reduction: Pyrolysis offers a powerful alternative to landfills by converting the bulk of organic waste into a smaller volume of useful products.

- If your primary focus is resource recovery: This technology excels at extracting valuable hydrocarbons from waste plastics and rubber, reducing reliance on virgin resources.

- If your primary focus is alternative energy: Pyrolysis provides a direct pathway for creating liquid and gaseous biofuels from a wide range of non-food biomass.

Ultimately, choosing pyrolysis is a strategic decision to treat waste not as an endpoint, but as a valuable beginning.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Waste Transformation | Converts plastics, tires, biomass into valuable products like biofuels and chemicals. |

| Environmental Impact | Reduces landfill use and greenhouse gas emissions compared to traditional disposal. |

| Economic Value | Creates revenue streams from waste materials, turning disposal costs into profits. |

| Feedstock Flexibility | Processes a wide range of organic materials, adapting to various waste streams. |

| Energy Efficiency | Modern systems capture and reuse heat, lowering operational costs and environmental footprint. |

Ready to transform your waste streams into valuable resources? KINTEK specializes in advanced pyrolysis equipment and consumables for laboratories and industrial applications. Our solutions are designed to help you efficiently convert organic waste into biofuels and recoverable materials, supporting your sustainability goals and reducing operational costs. Contact us today to learn how our expertise can help you implement a successful pyrolysis strategy tailored to your needs.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What are the advantages of pyrolysis technology? Turn Waste into Profit and Reduce Emissions

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time

- What are the different types of pyrolysis machines? Choose the Right System for Your Output