At its core, the magnetic field in magnetron sputtering is used to trap electrons near the surface of the material being sputtered (the target). This confinement dramatically increases the probability of these electrons ionizing the sputtering gas (like argon), creating a dense plasma that bombards the target more effectively. The result is a much faster, more efficient, and lower-temperature deposition process.

The fundamental challenge in sputtering is creating enough ions to erode the target material efficiently. The magnetic field solves this by acting as an "electron trap," concentrating the plasma's energy where it's needed most—directly at the target—transforming sputtering from a slow, high-pressure process into a fast and precise one.

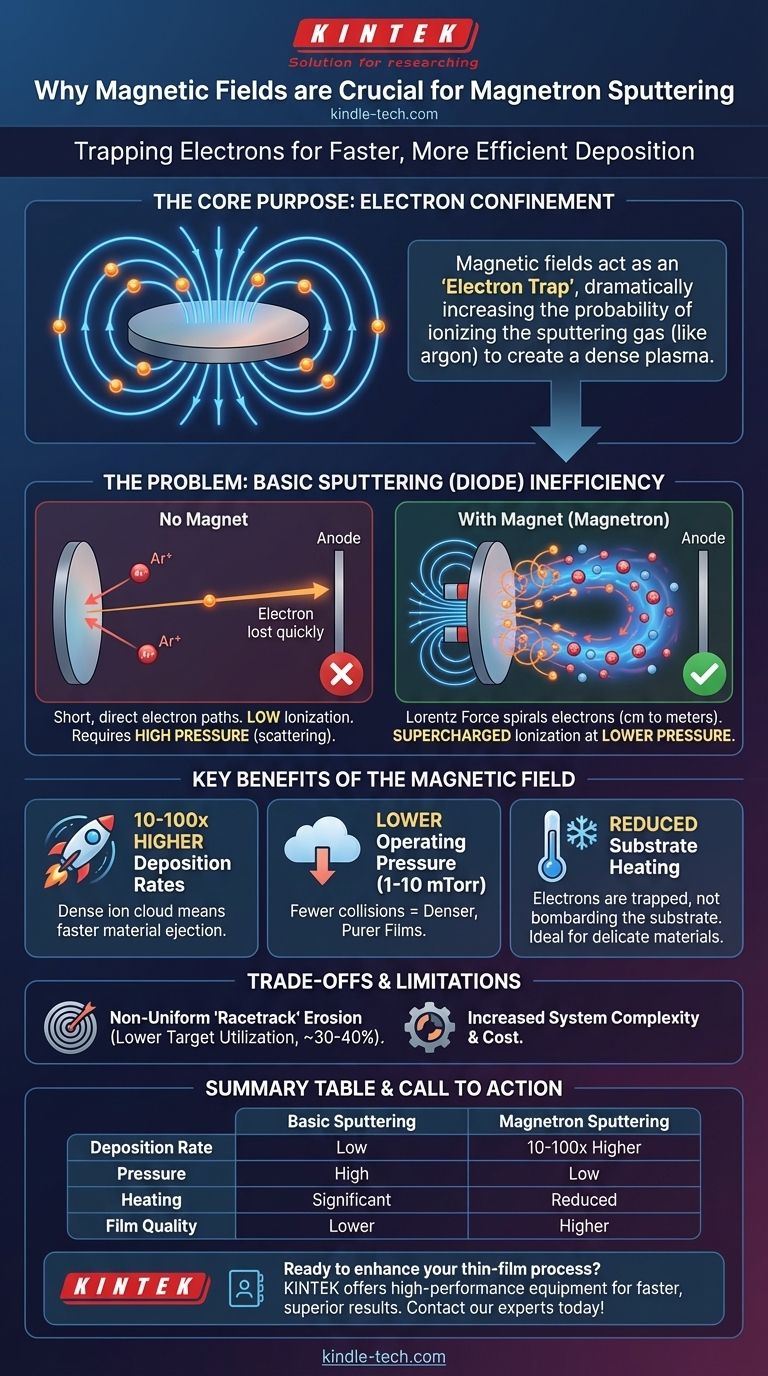

The Core Problem: Inefficiency in Basic Sputtering

To understand the role of the magnetic field, we must first look at the limitations of sputtering without one (known as diode sputtering).

The Role of Plasma

Sputtering works by creating a plasma, which is a super-heated, ionized gas. Positively charged ions from this plasma, typically argon (Ar+), are accelerated by an electric field and slam into the negatively charged target.

This high-energy bombardment physically knocks atoms loose from the target material. These ejected atoms then travel through the vacuum chamber and deposit as a thin film onto your substrate.

The Wasteful Path of Electrons

When an ion strikes the target, it not only dislodges target atoms but also knocks out secondary electrons. In basic sputtering, these light, energetic electrons are immediately attracted to the positive anode (often the chamber walls) and are lost.

Their path is too short and direct to be useful. They do not have enough time or a long enough path to collide with and ionize many neutral argon atoms, making the process of sustaining the plasma very inefficient.

The Need for High Pressure

To compensate for this inefficiency, diode sputtering requires relatively high gas pressure. More gas atoms in the chamber mean a slightly higher chance of an electron-atom collision.

However, high pressure is undesirable. It causes the sputtered atoms to scatter as they travel to the substrate, reducing deposition rate and potentially compromising the quality and density of the final film.

How the Magnetic Field Solves the Problem

Magnetron sputtering introduces a strategic magnetic field, typically created by permanent magnets placed behind the target, which fundamentally changes the behavior of the electrons.

Creating the "Electron Trap"

The magnetic field lines emerge from the target, loop around in front of its surface, and re-enter it. Due to a principle known as the Lorentz force, electrons are forced to follow these magnetic field lines in a tight spiral path.

They are effectively trapped in a "magnetic tunnel" or "racetrack" region close to the target surface, unable to escape directly to the chamber walls.

Increasing Electron Path Length

Instead of traveling a few centimeters in a straight line, a trapped electron's path length is extended to many meters as it spirals endlessly. Even though the electron stays physically close to the target, its total travel distance increases by several orders of magnitude.

Enhancing Ionization Efficiency

This vastly increased path length dramatically raises the probability that a single electron will collide with and ionize hundreds or thousands of neutral argon atoms before it loses its energy.

This supercharges the ionization process. A single secondary electron can now create a cascade of new ions, making the plasma self-sustaining at much lower pressures.

Generating a Dense, Localized Plasma

The result is a very dense, high-intensity plasma that is concentrated in the "racetrack" region directly over the target. This ensures a massive supply of ions is available right where they are needed for bombarding and sputtering the target material.

The Practical Benefits of Magnetron Sputtering

This elegant solution provides several critical, real-world advantages over basic sputtering.

Higher Deposition Rates

With a far denser cloud of ions bombarding the target, material is ejected at a much higher rate. Deposition rates for magnetron sputtering can be 10 to 100 times faster than for simple diode sputtering.

Operation at Lower Pressures

Because ionization is so efficient, the process can be run at much lower gas pressures (typically 1-10 mTorr). This creates a "mean free path" for the sputtered atoms, allowing them to travel directly to the substrate with fewer collisions, resulting in higher quality, denser films.

Reduced Substrate Heating

By trapping electrons at the target, the magnetron prevents them from bombarding and heating the substrate. This is a crucial advantage for depositing films onto heat-sensitive materials like polymers, plastics, or delicate electronic components.

Understanding the Trade-offs and Limitations

While powerful, the magnetron technique is not without its own set of considerations.

Non-Uniform Target Erosion

The plasma is confined to the magnetic "racetrack," meaning erosion only happens in this specific zone. This leads to the formation of a deep groove in the target material, leaving the center and outer edges unused. This reduces the effective utilization of the target material, often to just 30-40%.

System Complexity and Cost

Integrating a magnet assembly behind the target and ensuring proper cooling adds a layer of mechanical complexity and cost to the sputtering system compared to a simple diode setup.

Balanced vs. Unbalanced Fields

The shape of the magnetic field can be tuned. A balanced field confines the plasma very tightly to the target, maximizing the deposition rate. An unbalanced field allows some of the plasma to expand toward the substrate, which can be used intentionally to densify the growing film through light ion bombardment.

Making the Right Choice for Your Goal

The decision to use a magnetron is based on your specific application needs for speed, quality, and substrate compatibility.

- If your primary focus is high-speed deposition: Magnetron sputtering is non-negotiable for achieving commercially viable throughput and fast coating times.

- If your primary focus is coating sensitive substrates: The dramatically lower substrate heating from magnetron sputtering is a critical and enabling advantage.

- If your primary focus is achieving high film purity and density: The ability to operate at low pressure with a magnetron reduces gas incorporation and improves film structure.

- If your primary focus is ultimate simplicity and low cost for basic research: A simple diode sputtering system may suffice, but you must accept its significant limitations in performance.

Ultimately, the magnetic field transforms sputtering from a slow, brute-force method into the precise and highly efficient cornerstone of modern thin-film technology.

Summary Table:

| Feature | Basic Sputtering (No Magnet) | Magnetron Sputtering (With Magnet) |

|---|---|---|

| Deposition Rate | Low | 10-100x Higher |

| Operating Pressure | High (causes scattering) | Low (1-10 mTorr) |

| Substrate Heating | Significant | Greatly Reduced |

| Film Quality | Lower density, more defects | Higher density, purer films |

| Target Utilization | Uniform erosion | ~30-40% (racetrack erosion) |

Ready to enhance your thin-film deposition process? KINTEK specializes in high-performance magnetron sputtering equipment and consumables designed to meet the demanding needs of modern laboratories. Our solutions deliver faster deposition rates, superior film quality, and compatibility with heat-sensitive substrates.

Contact our experts today to discuss how our lab equipment can optimize your research and production outcomes!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Evaporation Boat for Organic Matter

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

People Also Ask

- What is the mechanism of spark plasma sintering? Unlock Rapid, Low-Temperature Densification

- What is the use of hot isostatic pressing? Achieve Flawless Material Integrity for Demanding Applications

- What temp is required for brazing? A Guide to Perfect Filler Metal Flow & Strong Joints

- What catalyst is used in catalytic pyrolysis? Zeolites for Superior Bio-Oil Upgrading

- What are the catalysts for biomass? Choosing the Right Catalyst for Your Biorefinery Process

- What is the principle of furnace? Mastering Heat with Resistance, Induction & Vacuum

- Is pyrolysis oil toxic? Understanding the Health and Safety Risks of Bio-Oil

- Why can graphite conduct heat? Unlocking Its Anisotropic Thermal Properties