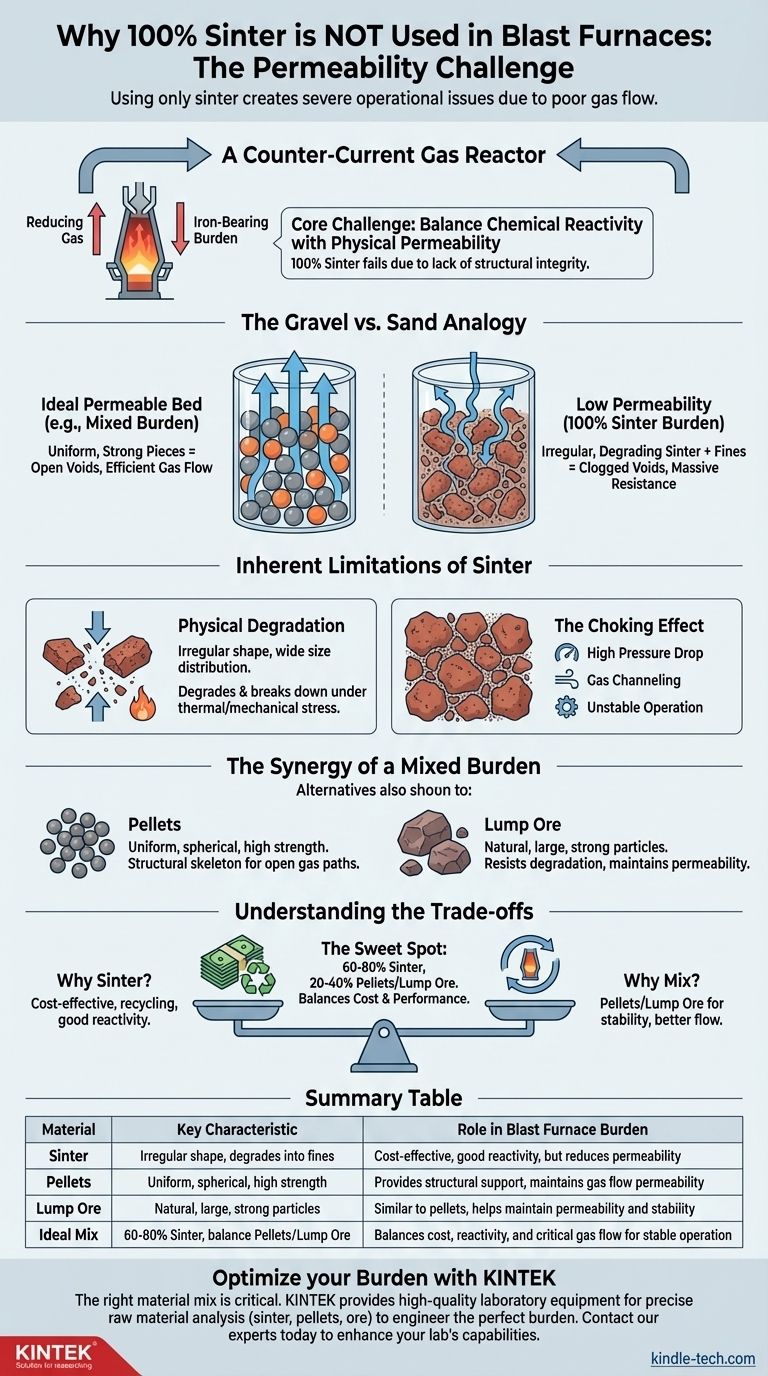

Using 100% sinter is not practical for a modern blast furnace because it creates severe operational problems related to poor gas permeability. Sinter's irregular shape and tendency to break down into fine particles can choke the flow of essential reducing gases up through the furnace, crippling its efficiency, stability, and output. While sinter is a vital and cost-effective component, it cannot perform the job alone.

The ideal blast furnace burden is an engineered mixture of materials, not a single, uniform ingredient. The core challenge is to balance chemical reactivity with physical strength and permeability. A 100% sinter burden fails this challenge because it lacks the structural integrity needed to maintain an open, permeable column for efficient gas flow.

The Central Role of Permeability

A Counter-Current Gas Reactor

Think of a blast furnace as a giant, vertical reactor. A hot, carbon monoxide-rich gas is forced in at the bottom and must travel upwards. Iron-bearing materials (the "burden") are loaded at the top and slowly descend.

The entire process depends on intimate contact between the rising gas and the descending solids. If the gas cannot flow freely and uniformly, the reaction is incomplete, fuel is wasted, and the furnace's operation becomes unstable.

The Gravel vs. Sand Analogy

Imagine trying to blow air through a tall cylinder filled with uniform, round gravel. The air would pass through easily because of the large, consistent voids between the pieces. This is an ideal, highly permeable bed.

Now, imagine that cylinder is filled with a mix of gravel, sand, and dust. Trying to blow air through it would be extremely difficult. The fine particles clog the voids, creating massive resistance. This is a low-permeability bed, and it's precisely the problem a 100% sinter burden creates.

The Inherent Limitations of Sinter

Physical Shape and Degradation

Sinter is produced by fusing fine iron ore particles into a porous, cake-like mass, which is then crushed and screened. By its nature, it is irregularly shaped and has a wide size distribution, which includes unavoidable fine particles from the start.

More importantly, as the sinter descends through the furnace, it is subjected to immense mechanical pressure from the tons of material above it and extreme thermal stress. This causes it to degrade and break down, generating even more fine particles directly inside the furnace shaft.

The Choking Effect

These newly created fines fill the gaps between the larger pieces of the burden. This clogging action drastically reduces the permeability of the entire column of material.

The consequences are severe:

- High Pressure Drop: The blowers must work much harder to force gas through the furnace, wasting energy.

- Gas Channeling: The gas, unable to flow uniformly, will find paths of least resistance and "channel" upwards, bypassing large portions of the burden.

- Unstable Operation: Poor gas-solid contact leads to inefficient reduction, unpredictable furnace behavior, and potential safety issues like "slips" and "hanging."

The Synergy of a Mixed Burden

To counteract the weaknesses of sinter, operators blend it with materials that provide structural support and maintain permeability.

The Advantage of Pellets

Iron ore pellets are small, spherical balls of ore that are fired to be very hard and durable. Their key advantages are uniform size and high strength.

When mixed into the burden, their spherical shape creates a highly predictable and permeable bed, like the gravel in our analogy. They act as a structural skeleton, holding open the pathways for gas to flow evenly throughout the furnace.

The Role of Lump Ore

High-quality lump ore can serve a similar function. It is natural, high-grade ore that is simply crushed and screened. Like pellets, it provides larger, stronger particles that resist degradation and help maintain the permeability of the burden.

Understanding the Trade-offs

Why Use Sinter at All?

If sinter has these physical drawbacks, why is it the dominant burden material in many parts of the world? The reasons are primarily economic and chemical.

Sintering is an excellent way to use lower-cost fine iron ores that cannot be charged directly into the furnace. It is also a critical process for recycling in-plant waste materials like flue dust and coke fines, turning waste streams into valuable feedstock. Furthermore, its porous structure gives it excellent chemical reactivity (reducibility).

The Cost vs. Performance Balance

The decision of how much sinter, pellets, or lump ore to use is a constant balancing act. A higher percentage of pellets leads to smoother, more productive furnace operation but often comes with a higher raw material cost. Maximizing sinter usage lowers cost but requires more careful control to manage the risk of instability.

Most modern blast furnaces have found a sweet spot, typically running a burden with 60-80% sinter and making up the difference with pellets and/or lump ore to achieve optimal performance.

Making the Right Choice for Your Goal

Choosing the right burden mix is a strategic decision that balances productivity, stability, and cost.

- If your primary focus is maximizing productivity and stability: Prioritize a higher percentage of high-quality, uniformly sized pellets and lump ore to ensure excellent permeability, even if it increases raw material costs.

- If your primary focus is minimizing operational cost: Maximize the use of sinter to consume cheaper ore fines and recycle plant waste, but accept the need for sophisticated process control to manage permeability.

- If your primary focus is supply chain resilience: Develop the operational flexibility to use a varied mix of sinter, pellets, and lump ore to adapt to changing market prices and raw material availability.

Ultimately, a blast furnace operates best not with a single "perfect" ingredient, but with a synergistic blend of materials engineered for both chemical reaction and physical flow.

Summary Table:

| Material | Key Characteristic | Role in Blast Furnace Burden |

|---|---|---|

| Sinter | Irregular shape, degrades into fines | Cost-effective, good reactivity, but reduces permeability |

| Pellets | Uniform, spherical, high strength | Provides structural support, maintains gas flow permeability |

| Lump Ore | Natural, large, strong particles | Similar to pellets, helps maintain permeability and stability |

| Ideal Mix | 60-80% Sinter, balance Pellets/Lump Ore | Balances cost, reactivity, and critical gas flow for stable operation |

Optimize your blast furnace burden for maximum efficiency and stability. The right material mix is critical for maintaining permeability and preventing costly operational issues. KINTEK specializes in providing high-quality laboratory equipment and consumables for analyzing raw materials like sinter, pellets, and ore. Our solutions help you precisely characterize material properties to engineer the perfect burden for your specific goals. Contact our experts today to discuss how we can support your ironmaking process and enhance your lab's capabilities.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

People Also Ask

- Why is a quartz tube furnace utilized in the thermal oxidation of MnCr2O4 coatings? Unlock Precise Selective Oxidation

- What materials are used for the tubes in tube furnaces? A Guide to Selecting the Right Tube for Your Process

- What is a tubular furnace used for? Precision Heating for Material Synthesis & Analysis

- How to clean a tube furnace? A Step-by-Step Guide for Safe and Effective Maintenance

- How does a high-temperature tube furnace facilitate the phase transformation of alumina products? Master Thermal Control