Calendering is a critical finishing process used to intentionally alter the physical properties of a fabric. Its primary functions are to create a smoother surface, impart a specific luster or shine, and significantly improve the fabric's "hand," which is the technical term for how it feels to the touch.

Calendering is not merely a cosmetic step; it is a precise mechanical process that uses pressure to deliberately engineer the final look, feel, and performance of a textile, transforming it from a raw material into a finished product.

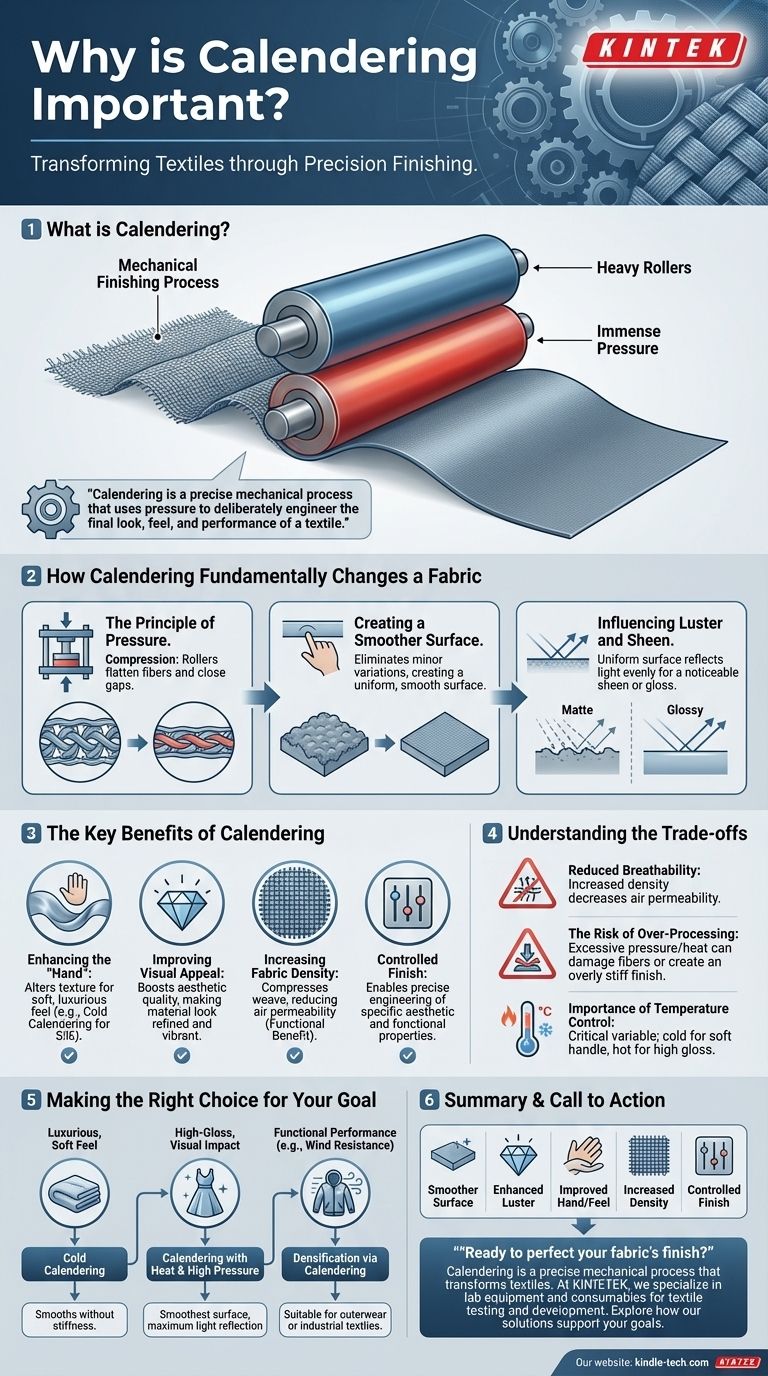

How Calendering Fundamentally Changes a Fabric

Calendering is a mechanical finishing process where fabric is passed between two or more large, heavy rollers. These rollers apply immense pressure, and sometimes heat, to flatten the fibers and yarn within the fabric's weave.

The Principle of Pressure

The core mechanism of calendering is compression. The rollers press the yarns, flattening them and closing the gaps between them in the fabric's structure.

Creating a Smoother Surface

By flattening the individual fibers and the overall weave, the calendering process eliminates minor surface variations. This results in a much smoother, more uniform fabric surface.

Influencing Luster and Sheen

A fabric's luster is determined by how it reflects light. A rough, uncalendered surface scatters light in many directions, appearing matte. A smooth, calendered surface reflects light more uniformly, creating a noticeable sheen or gloss.

The Key Benefits of Calendering

The changes made during calendering produce specific, desirable outcomes that are crucial for a fabric's intended application.

Enhancing the "Hand" or Feel

The term "hand" or "handle" refers to the tactile qualities of a fabric. Calendering directly influences this by altering the texture.

For example, silk is often calendered in a cold state. This process smooths the fibers without making them stiff, resulting in the soft, luxurious handle for which silk is known.

Improving Visual Appeal

Beyond just feel, the process significantly boosts a fabric's aesthetic quality. The light luster created by the smooth surface makes the material look more refined, vibrant, and expensive.

Increasing Fabric Density

A direct result of compressing the fibers is an increase in fabric density. This can be a purely aesthetic choice or a functional one, as it often leads to reduced air permeability, making the fabric more resistant to wind.

Understanding the Trade-offs

While highly effective, the calendering process involves important considerations and potential downsides that must be managed.

Reduced Breathability

The same compression that increases density and smoothness also reduces the space between fibers. This can significantly decrease the fabric's breathability, which may be undesirable for certain types of apparel.

The Risk of Over-Processing

Applying excessive pressure or heat can damage delicate fibers. It can also create an overly stiff or plastic-like finish, permanently ruining the fabric's desired hand and appearance.

The Importance of Temperature Control

As the example with silk illustrates, temperature is a critical variable. Cold calendering produces a soft handle, while hot calendering (not mentioned for silk) is used on other fabrics to create a much higher gloss and a stiffer finish. The choice depends entirely on the desired outcome.

Making the Right Choice for Your Goal

The decision to calender a fabric and the specific method used should always be driven by the end goal for the product.

- If your primary focus is a luxurious, soft feel: Cold calendering is often the best choice, as it smooths the fabric without creating stiffness.

- If your primary focus is a high-gloss, visual impact: Calendering with heat and high pressure will create the smoothest possible surface for maximum light reflection.

- If your primary focus is functional performance like wind resistance: The densification from calendering can be a key benefit, making it suitable for outerwear or industrial textiles.

Ultimately, calendering provides precise control, allowing manufacturers to transform a standard textile into a material with specific aesthetic and tactile qualities.

Summary Table:

| Key Benefit | Description |

|---|---|

| Smoother Surface | Flattens fibers to eliminate variations and create a uniform finish. |

| Enhanced Luster | Reflects light uniformly for a noticeable sheen or gloss. |

| Improved Hand/Feel | Alters tactile qualities for a softer or more luxurious texture. |

| Increased Density | Compresses weave to boost wind resistance and reduce permeability. |

| Controlled Finish | Uses pressure and heat to engineer specific aesthetic and functional properties. |

Ready to perfect your fabric's finish? Calendering is a precise mechanical process that transforms textiles from raw materials into high-performance products. At KINTEK, we specialize in lab equipment and consumables for textile testing and development, helping you achieve the exact look, feel, and durability your fabrics need. Whether you're focusing on luxurious softness, high-gloss visuals, or functional wind resistance, our solutions support your goals. Contact us today to explore how KINTEK can enhance your textile finishing processes!

Visual Guide

Related Products

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

- Powerful Plastic Crusher Machine

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Precision Wire Saw Laboratory Cutting Machine with 800mm x 800mm Workbench for Diamond Single Wire Circular Small Cutting

- 12 Inch 24 Inch High Precision Automatic Diamond Wire Cutting Machine Laboratory Saw Precision Wire EDM Cutting Machine

People Also Ask

- What is the use of two roll mill? Essential for Polymer Mixing, R&D, and Quality Control

- What are the two common types of injection molding processes? Thermoplastic vs. Thermoset Explained

- What does calendering do for fabric? Transform Fabric's Look, Feel, and Performance

- What are the ingredients used in rubber compounding? A Guide to the Essential Formula

- What is the screw extrusion process? A Guide to Continuous Plastic Profiling

- What is the process of pyrolysis of rubber? A Step-by-Step Guide to Converting Waste into Fuel

- What is vulcanizing used for? Unlock the Strength and Durability of Rubber

- What is the process of multilayer co extrusion? Engineer High-Performance Composite Materials