At its core, diamond is used for cutting tools for one primary reason: it is the hardest known material on Earth. This extreme hardness translates directly into superior wear resistance, allowing a diamond-tipped tool to maintain a sharp cutting edge far longer than any other material, especially when machining highly abrasive or hard substances.

The choice to use diamond tooling is a strategic decision to achieve maximum performance and tool life when working with non-ferrous metals, composites, and ceramics. However, its chemical reactivity with iron makes it fundamentally unsuitable for machining steel and other ferrous alloys.

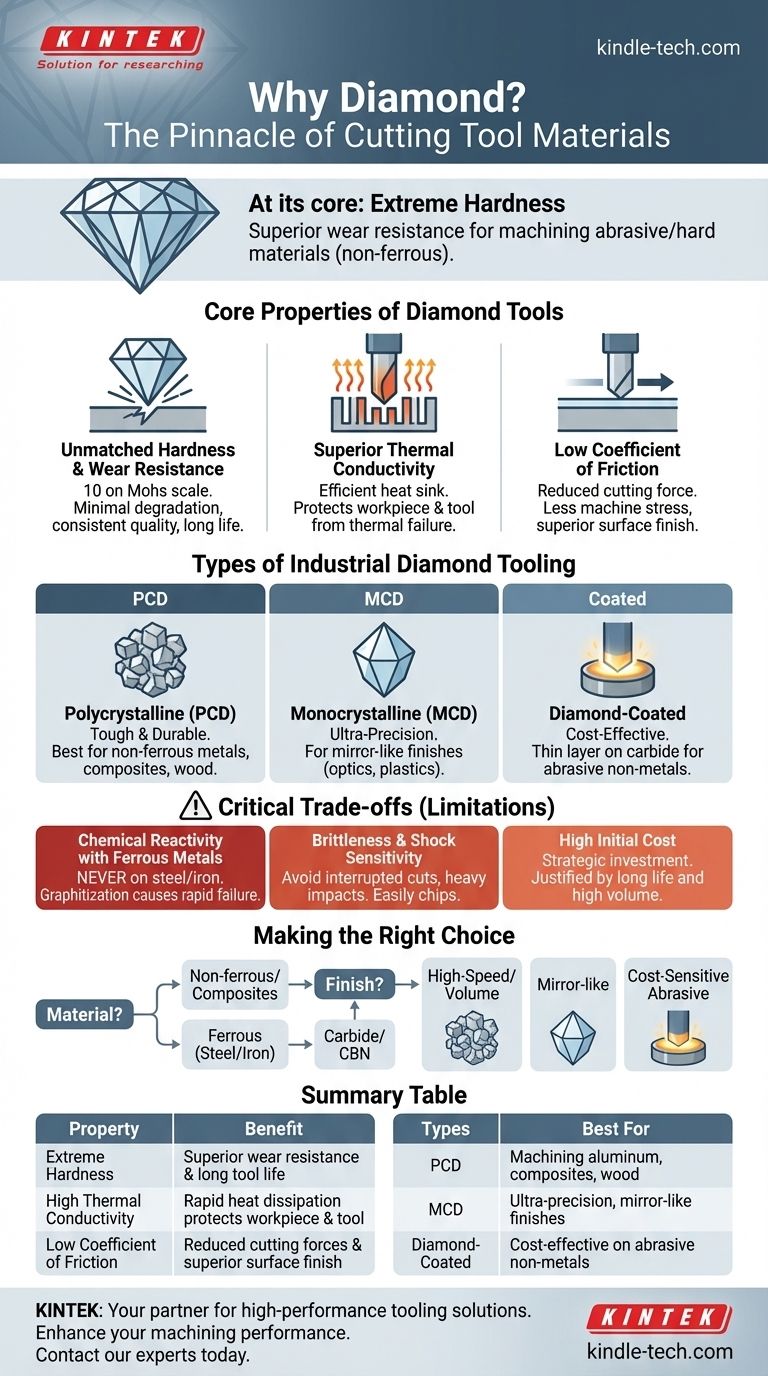

The Core Properties of Diamond Tools

To understand why diamond is so effective, we must look beyond its famous hardness and consider its other unique thermal and physical properties.

Unmatched Hardness and Wear Resistance

The defining characteristic of diamond is its rating of 10 on the Mohs hardness scale. In a manufacturing context, this means a diamond cutting edge can shear through difficult materials with minimal degradation.

This results in exceptionally long tool life and consistent part quality over extended production runs, as the tool's geometry does not change due to wear.

Superior Thermal Conductivity

Diamond is an exceptional thermal conductor, far better than copper or silver. During high-speed machining, immense heat is generated at the cutting point.

A diamond tool acts like a highly efficient heat sink, rapidly pulling this thermal energy away from the workpiece and the tool tip. This prevents heat damage to the workpiece and protects the tool itself from thermal failure.

Low Coefficient of Friction

Diamond has a very low coefficient of friction, meaning it glides through the material being cut with less resistance.

This has two key benefits: it reduces the cutting forces required, putting less stress on the machine, and it helps produce a superior surface finish on the final part by minimizing material tearing.

Types of Industrial Diamond Tooling

"Diamond tooling" is not a single category. The type of diamond used is engineered for specific applications and cost considerations.

Polycrystalline Diamond (PCD)

PCD is the most common form of industrial diamond. It consists of microscopic diamond crystals sintered together with a metallic binder under extreme pressure and temperature.

This creates a tough, wear-resistant layer that is ideal for machining non-ferrous metals (like aluminum alloys), composites (like carbon fiber), and wood products. It offers a great balance of performance and durability.

Monocrystalline Diamond (MCD)

MCD, also known as single-crystal diamond, is a flawless, lab-grown diamond. It can be honed to an incredibly sharp and perfect cutting edge, measured in nanometers.

Its sole purpose is ultra-precision machining to create mirror-like finishes on materials like plastics, aluminum, and copper, often for optical components. MCD is more brittle and expensive than PCD.

Diamond-Coated Tools

For a more cost-effective solution, a thin layer of diamond can be deposited onto a tougher tool substrate (like tungsten carbide) using Chemical Vapor Deposition (CVD).

This provides the hardness and low friction of a diamond surface while retaining the toughness and lower cost of the carbide body. However, the coating is thin and can be stripped away under aggressive use.

Understanding the Critical Trade-offs

Despite its advantages, diamond is not a universal solution. Its limitations are just as important to understand as its strengths.

Chemical Reactivity with Ferrous Metals

This is the most significant limitation. At the high temperatures generated when cutting steel or cast iron, a chemical reaction occurs where the carbon atoms in the diamond diffuse into the iron.

This process, known as graphitization, rapidly breaks down the diamond's structure, causing catastrophic and immediate tool failure. For this reason, diamond tools are never used to machine ferrous metals.

Brittleness and Shock Sensitivity

While incredibly hard, diamond is also brittle. It has low fracture toughness, meaning it can easily chip or shatter if subjected to sudden impacts, shock loads, or heavy vibrations.

This makes it unsuitable for "interrupted cuts" where the tool repeatedly enters and exits the material, as each impact poses a risk of fracture.

High Initial Cost

Diamond tooling carries a significantly higher upfront cost compared to carbide or high-speed steel tools. This cost must be justified by the application.

The investment is typically recouped through much longer tool life, faster cutting speeds, and reduced machine downtime for tool changes, leading to a lower overall cost-per-part in high-volume production.

Making the Right Choice for Your Application

Selecting the right cutting tool material is essential for efficiency, quality, and cost-effectiveness.

- If your primary focus is machining aluminum, brass, or composites: PCD is the industry standard, offering unmatched tool life and high-speed capability.

- If your primary focus is achieving a mirror-like surface finish: MCD is the only choice for creating ultra-precise optical surfaces on non-ferrous materials.

- If your primary focus is machining steel, stainless steel, or cast iron: Do not use diamond. Use appropriate grades of carbide, ceramic, or cubic boron nitride (CBN) tools instead.

- If your primary focus is a cost-sensitive application on abrasive non-metals: Diamond-coated carbide tools can provide a significant performance boost over standard carbide.

Ultimately, using a diamond tool is a strategic investment in performance for a specific set of demanding materials.

Summary Table:

| Property | Benefit for Tooling |

|---|---|

| Extreme Hardness | Superior wear resistance & long tool life |

| High Thermal Conductivity | Rapid heat dissipation protects workpiece & tool |

| Low Coefficient of Friction | Reduced cutting forces & superior surface finish |

| Types | Best For |

| PCD (Polycrystalline Diamond) | Machining aluminum, composites, wood |

| MCD (Monocrystalline Diamond) | Ultra-precision, mirror-like finishes |

| Diamond-Coated Tools | Cost-effective performance on abrasive non-metals |

Ready to enhance your machining performance with the right diamond tooling?

KINTEK specializes in high-performance lab equipment and consumables, including precision tooling solutions. Whether you're machining advanced composites, non-ferrous metals, or require ultra-precise finishes, our expertise can help you select the ideal tool to maximize efficiency, tool life, and part quality.

Contact our experts today to discuss your specific application and discover how KINTEK's solutions can drive your productivity forward.

Visual Guide

Related Products

- CVD Diamond Dressing Tools for Precision Applications

- CVD Diamond Cutting Tool Blanks for Precision Machining

- CVD Diamond Domes for Industrial and Scientific Applications

- CVD Diamond Optical Windows for Lab Applications

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

People Also Ask

- What are diamond coated tools used for? Conquer Abrasive Materials with Superior Tool Life

- What is the carbon footprint of diamond mining? Uncovering the True Environmental and Ethical Cost

- What are the properties of diamond coating? Unlock Extreme Performance for Your Components

- What is the application of diamond coating? Solve Complex Wear, Heat, and Corrosion Problems

- How thick is diamond coating? Achieve Unprecedented Precision with Ultra-Thin Films