In short, cleaning sieves before and after every test is essential for two primary reasons: to ensure the accuracy of your results by preventing cross-contamination and to maintain the physical integrity of the sieve itself. A contaminated or damaged sieve is no longer a reliable measurement tool, which compromises the validity of any analysis performed with it.

A test sieve is a precision measuring instrument, not just a filter. Treating it with the same care as any other calibrated lab equipment is fundamental to producing trustworthy and repeatable data.

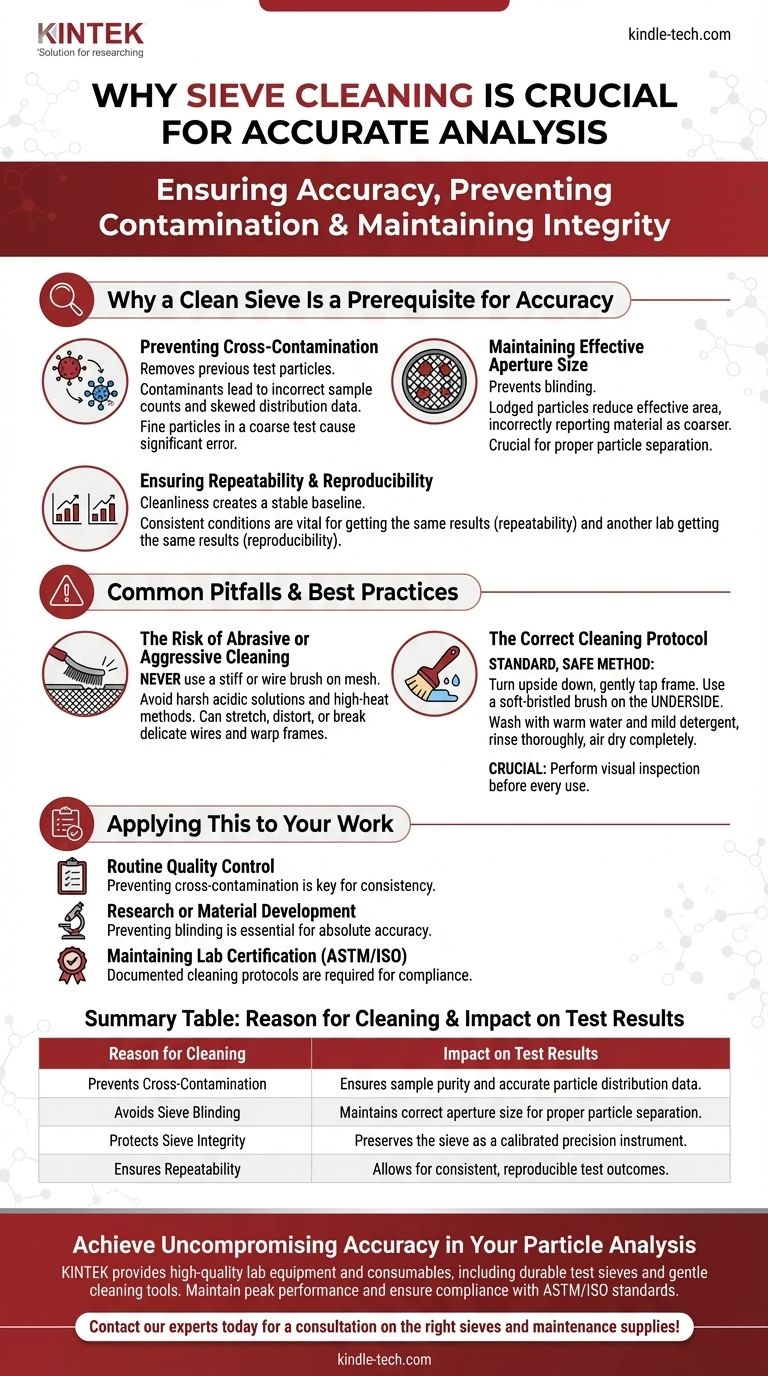

Why a Clean Sieve Is a Prerequisite for Accuracy

A common mistake is to view a test sieve as a durable, simple piece of hardware. In reality, its performance is defined by the precise, uniform dimensions of its mesh openings. Any deviation compromises its function as a measurement device.

Preventing Cross-Contamination

The most immediate reason for cleaning is to remove all particles from a previous test.

If material from a prior analysis remains in the mesh, it will be added to the next sample. This introduces a significant error, especially if the new sample size is small or has a different particle distribution.

For example, if fine sand particles remain trapped in a sieve that is then used to test coarse gravel, those sand particles will be incorrectly counted as part of the gravel sample, skewing the final particle size distribution.

Maintaining Effective Aperture Size

A sieve works by allowing particles smaller than the mesh openings to pass through. When particles become lodged in these openings—a condition known as blinding—the effective area for separation is reduced.

This means fewer particles will pass through the sieve in a given amount of time, leading to an inaccurate result. The analysis will incorrectly report that the material is coarser than it actually is because a portion of the finer particles was unable to pass through the clogged mesh.

Ensuring Repeatability and Reproducibility

The foundation of any valid scientific or quality control test is its ability to be repeated. If a sieve is not consistently clean, the test conditions are never the same.

Inconsistent cleaning practices make it impossible to achieve repeatability (getting the same result on the same sample) or reproducibility (having another lab get the same result). Cleanliness creates a stable baseline for every analysis.

Common Pitfalls and Best Practices

While cleaning is critical, how you clean is just as important. Improper cleaning can damage the sieve, creating an entirely different set of accuracy problems.

The Risk of Abrasive or Aggressive Cleaning

Never use a stiff or wire brush on the mesh, especially on finer sieves. Doing so can stretch, distort, or even break the delicate woven wires, altering the aperture dimensions permanently.

Likewise, avoid harsh acidic solutions, as they can corrode the mesh. High-heat methods like lab ovens or dishwashers can also warp the frame and damage the epoxy that secures the mesh.

The Correct Cleaning Protocol

The standard, safe method involves a few simple steps. After each use, turn the sieve upside down over a clean pan and gently tap the frame.

Use a soft-bristled sieve brush on the underside of the mesh to dislodge any remaining particles. If necessary, wash the sieve with warm water and a mild detergent, then rinse thoroughly and allow it to air dry completely before the next use.

The "Before and After" Mindset

Cleaning is not just an "after-test" task. A quick visual inspection before every use is a crucial final check. This confirms that the sieve is not only clean but also free from any damage that may have occurred during storage.

Applying This to Your Work

Your specific goals will determine which aspects of sieve maintenance are most critical to your operation.

- If your primary focus is routine quality control: Your goal is consistency, so preventing cross-contamination between batches is the most important reason to clean your sieves rigorously.

- If your primary focus is research or material development: You require absolute accuracy, making the prevention of blinding essential to ensure your particle size distribution data is completely reliable.

- If your primary focus is maintaining lab certification (ASTM/ISO): Proper, documented cleaning protocols are a non-negotiable part of the formal calibration and maintenance standards required for compliance.

Ultimately, this simple act of hygiene is what ensures your sieve remains a tool of precision.

Summary Table:

| Reason for Cleaning | Impact on Test Results |

|---|---|

| Prevents Cross-Contamination | Ensures sample purity and accurate particle distribution data. |

| Avoids Sieve Blinding | Maintains correct aperture size for proper particle separation. |

| Protects Sieve Integrity | Preserves the sieve as a calibrated precision instrument. |

| Ensures Repeatability | Allows for consistent, reproducible test outcomes. |

Achieve Uncompromising Accuracy in Your Particle Analysis

Properly maintained sieves are the foundation of reliable particle size distribution data. KINTEK understands that your laboratory's reputation depends on the precision of your equipment.

We specialize in providing high-quality lab equipment and consumables, including durable test sieves and gentle cleaning tools designed to protect your investment and ensure compliance with ASTM/ISO standards.

Let us help you maintain peak performance in your lab.

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Three-dimensional electromagnetic sieving instrument

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Multifunctional Small Speed-Adjustable Horizontal Mechanical Shaker for Lab

People Also Ask

- What is the process of sieve analysis? A Step-by-Step Guide to Particle Size Distribution

- What is the diameter of a test sieves? A Guide to Choosing the Right Size for Your Lab

- What are the uses of sieves in the laboratory? Master Particle Size for Quality & Performance

- What is sieve analysis in construction? Ensure Material Quality & Project Success

- What are the pros and cons of sieving? A Guide to Accurate Particle Size Analysis

- Why must Al2O3/ZrO2 ceramic powders undergo treatment with a standard sieve? Ensuring High-Density Sintering Results

- What is the sample size recommended for the sieve analysis? Avoid Overloading for Accurate Results

- What are the factors affecting sieving performance and efficiency? Optimize Your Particle Separation Process