The fundamental reason stainless steel is harder to work with is a unique combination of four properties: a high rate of work hardening, low thermal conductivity, high ductility, and a tough, passive surface layer. Unlike carbon steel which is more forgiving, stainless steel actively resists cutting, forming, and welding operations, demanding specific tools, techniques, and a deeper understanding of the material itself.

The very properties that make stainless steel desirable—its strength, toughness, and corrosion resistance—are the direct cause of the challenges it presents during fabrication. To work with it effectively is to understand and accommodate these inherent characteristics, not fight them.

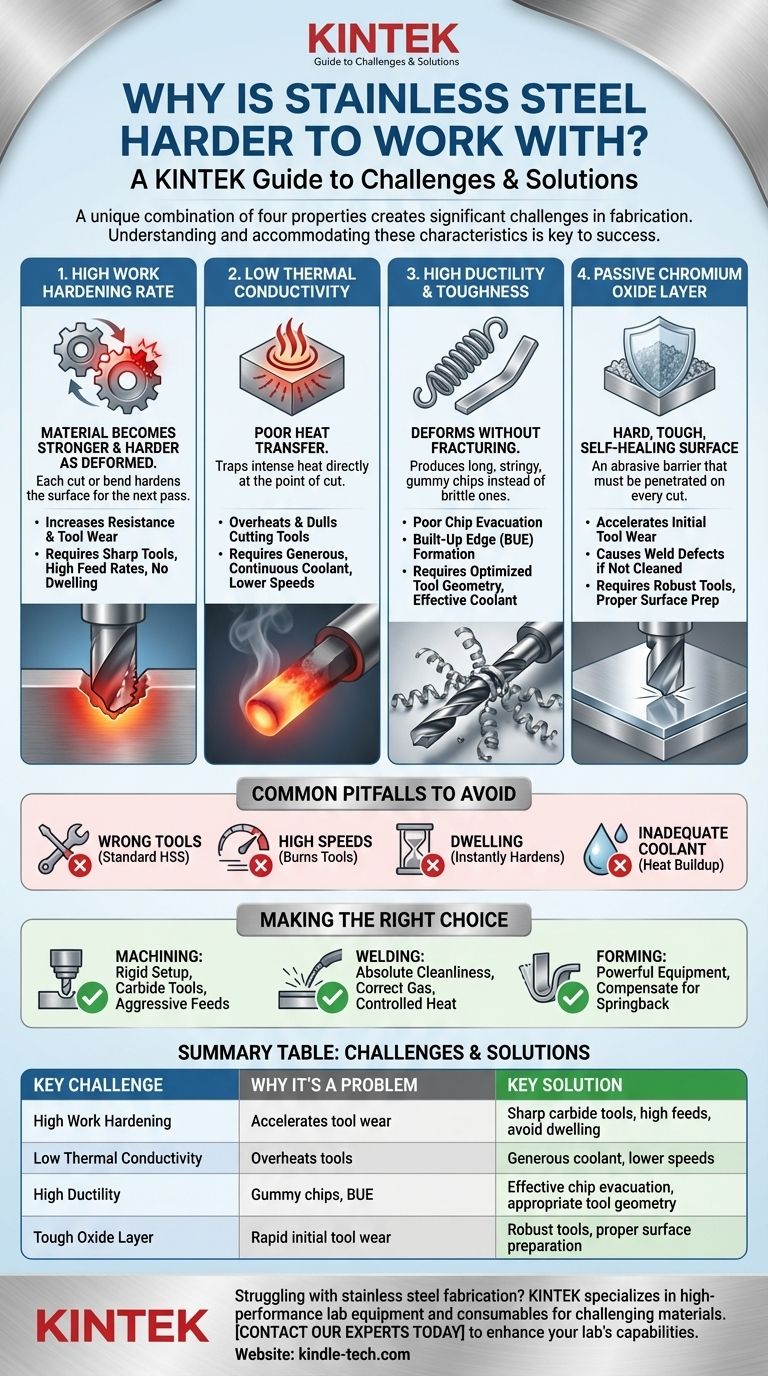

The Core Properties That Create Challenges

Understanding why stainless steel is difficult requires looking at its fundamental metallurgical properties. Each one creates a specific set of problems for the fabricator.

High Work Hardening Rate

Work hardening, or strain hardening, is a phenomenon where a metal becomes stronger and harder as it is plastically deformed.

Stainless steel, particularly austenitic grades like 304 and 316, has an exceptionally high work hardening rate.

This means that the very act of cutting, drilling, or bending the material instantly makes the surface you are working on significantly harder. The next pass of a tool must cut through material that is now harder than it was a moment ago, leading to a vicious cycle of increasing resistance and tool wear.

Low Thermal Conductivity

Thermal conductivity is a measure of how well a material transfers heat.

Most steels, like carbon steel, are relatively good conductors, allowing the intense heat generated by cutting to dissipate into the body of the workpiece and the chips.

Stainless steel is a poor thermal conductor. It traps heat directly at the point of the cut. This extreme concentration of heat doesn't soften the workpiece; instead, it overheats the cutting tool's edge, leading to rapid dulling, deformation, or even melting of the tool itself.

High Ductility and Toughness

Ductility is the ability of a material to deform without fracturing. While this makes stainless steel tough and resistant to impact, it creates problems in machining.

Instead of forming brittle chips that break away cleanly, the high ductility of stainless steel produces long, stringy, and gummy chips.

These chips do not evacuate easily, often wrapping around the tool and workpiece. This can mar the surface finish and, more critically, leads to a "built-up edge" (BUE), where small pieces of the workpiece weld themselves to the tool tip, ruining its cutting geometry and effectiveness.

The Passive Chromium Oxide Layer

The "stainless" quality of the steel comes from a microscopically thin, transparent layer of chromium oxide that forms on its surface when exposed to air.

This passive layer is extremely hard, tough, and self-healing. It provides excellent corrosion resistance but acts as an abrasive barrier that must be penetrated on every first cut.

This causes initial accelerated wear on the cutting tool edge. In welding, this same oxide layer can get trapped in the molten weld pool if not properly cleaned and shielded, causing defects and weak points in the final joint.

Common Pitfalls to Avoid

The unique properties of stainless steel mean that techniques used for carbon steel will often lead to failure. Avoiding common mistakes is critical for success.

Using the Wrong Tools, Speeds, or Feeds

Standard High-Speed Steel (HSS) tools will not last. You must use tools made of harder, more heat-resistant materials like cobalt HSS or solid carbide.

Furthermore, running the machine at the high speeds typical for mild steel will instantly burn up the tool due to stainless's low thermal conductivity. The correct approach is low surface speeds combined with a high, constant feed rate.

"Dwelling" During a Cut

Dwelling is when a cutting tool spins in one place without actively removing material.

With stainless steel, dwelling for even a fraction of a second will generate immense friction and heat, causing the surface to instantly work-harden to a point where it can become nearly unmachinable. The principle must be: get in, make the cut, and get out without hesitation.

Inadequate Coolant

Given the material's inability to dissipate heat, a generous and constant supply of high-quality coolant is not optional—it's essential.

Coolant does two things: it extracts heat from the tool-workpiece interface, preserving the tool's life, and it helps with chip evacuation, preventing the stringy chips from causing damage.

Ignoring the Specific Grade

Not all stainless steels are the same. A 303 or 416 "free-machining" grade is far more forgiving than a standard 304 or a high-temperature 310 grade.

Treating all stainless steel as one material is a recipe for frustration. Always identify the specific grade and consult its machining or welding guidelines.

Making the Right Choice for Your Goal

Success with stainless steel comes from selecting a strategy that directly counters its challenging properties.

- If your primary focus is Machining: Use extremely rigid setups, sharp carbide or cobalt tools, low speeds, aggressive feed rates, and a high volume of coolant to manage heat and prevent work hardening.

- If your primary focus is Welding: Ensure absolute cleanliness to remove the oxide layer, use the correct shielding gas (often a tri-mix), and control heat input carefully to minimize warping and distortion.

- If your primary focus is Forming: Use powerful equipment to overcome the high initial strength, and be sure to over-bend the material to compensate for its significant springback.

Ultimately, mastering stainless steel is not about fighting its nature, but respecting it with the right knowledge, tools, and techniques.

Summary Table:

| Key Challenge | Why It's a Problem | Key Solution |

|---|---|---|

| High Work Hardening Rate | Each cut makes the material harder, accelerating tool wear. | Use sharp carbide tools, high feed rates, and avoid dwelling. |

| Low Thermal Conductivity | Heat concentrates at the cut, rapidly overheating tools. | Apply generous coolant and use lower cutting speeds. |

| High Ductility | Produces gummy, stringy chips that can damage the workpiece. | Ensure effective chip evacuation and use appropriate tool geometry. |

| Tough Oxide Layer | The hard surface layer causes rapid initial tool wear. | Use robust tool materials and ensure proper surface preparation. |

Struggling with stainless steel fabrication? KINTEK specializes in providing high-performance lab equipment and consumables tailored for challenging materials like stainless steel. Our expertise ensures you have the right tools and support to achieve precise, efficient results. Contact our experts today to discover how we can enhance your laboratory's capabilities and streamline your workflow.

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Laboratory Single Horizontal Jar Mill

- Laboratory Planetary Ball Mill Cabinet Planetary Ball Milling Machine

People Also Ask

- What are the disadvantages of oil sludge? Avoid Catastrophic Engine Damage and Costly Repairs

- What are the risks of heat treatment? Avoid Material Failure and Operational Hazards

- What is the principle of sputter coater? A Guide to Thin Film Deposition via Magnetron Sputtering

- How much is the cost of pyrolysis plant? A Guide to Budgeting for Your Specific Project

- What is a magnetron sputtering? A Guide to High-Quality Thin-Film Deposition

- What is sintering process in additive manufacturing? A Guide to Powder-Based 3D Printing

- What is the product of slow pyrolysis? Tailor-Made Biochar, Oil, and Syngas from Biomass

- What elements cannot be detected by XRF? Understanding the Limits of Light Element Analysis