Zirconia is sintered to transform it from a soft, porous, and chalk-like material into a dense, high-strength ceramic. This carefully controlled heating process fuses the individual zirconia particles together, eliminating internal voids to achieve the material's final, clinically acceptable hardness and structural integrity.

The fundamental reason for sintering zirconia is densification. This process eliminates the microscopic pores within the material, which is the direct cause of its dramatic increase in mechanical strength, hardness, and esthetic translucency.

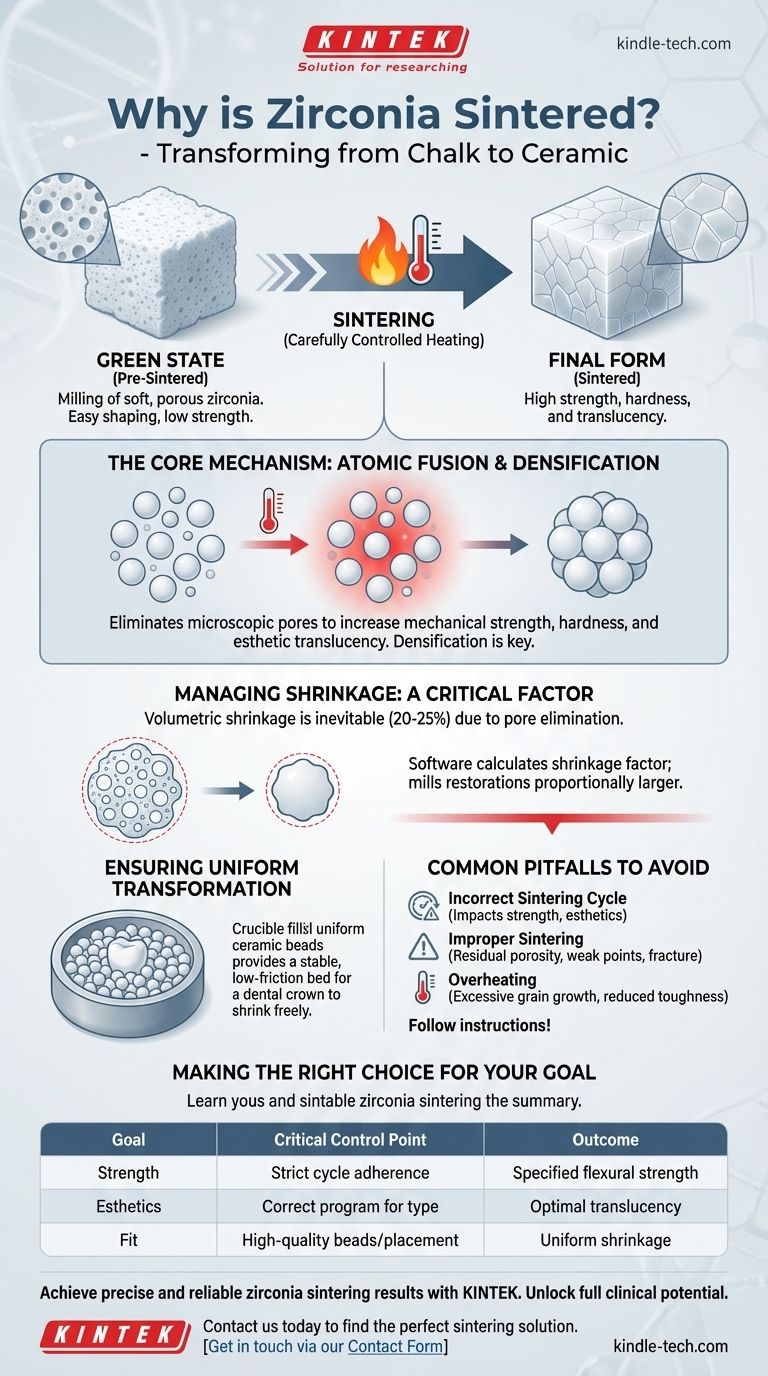

The Transformation from "Green State" to Final Form

Sintering is not merely a hardening process; it is a complete material transformation at the microscopic level. It's the critical step that converts a precisely milled shape into a functional, load-bearing component.

The "Green State" Starting Point

Before sintering, zirconia exists in a pre-sintered or "green state." In this phase, it is soft and chalky, making it easy and efficient to mill into complex shapes like dental crowns or bridges using CAD/CAM technology.

However, in this state, the material has virtually no structural strength because it is highly porous.

The Core Mechanism: Atomic Fusion

Sintering involves heating the green-state zirconia in a specialized furnace to temperatures just below its melting point.

This high heat energizes the zirconia particles, causing them to diffuse and fuse together at their contact points. As this fusion progresses, the gaps and pores between the particles are gradually eliminated.

The Result of Densification

The elimination of porosity is what gives sintered zirconia its remarkable properties. A denser material is inherently stronger and more resistant to fracture.

This process also significantly impacts the material's optical properties, increasing its translucency for better esthetic results in dental applications.

Managing the Critical Factor: Shrinkage

The most significant and predictable outcome of sintering is volumetric shrinkage. Understanding and managing this is essential for producing accurate final parts.

Why Shrinkage is Inevitable

Shrinkage is a direct and necessary consequence of densification. As the pores between the zirconia particles are eliminated, the overall volume of the object must decrease.

This shrinkage is substantial, often reducing the dimensions of the part by 20-25%.

The Role of CAD/CAM Software

To achieve a final product with precise dimensions, the initial milling must account for this shrinkage.

CAD/CAM software automatically calculates the required shrinkage factor and mills the green-state restoration proportionally larger than its intended final size.

Ensuring Uniform Transformation

To ensure the zirconia shrinks uniformly without warping or cracking, it is placed in a crucible filled with ceramic or zirconia beads.

These beads provide a stable, low-friction bed that allows the restoration to move and shrink freely in all directions as it densifies in the furnace.

Common Pitfalls to Avoid

The success of a zirconia restoration is heavily dependent on the precision of the sintering process. Deviations can compromise the final outcome.

Impact of Sintering Parameters

The final properties of zirconia are dictated by the sintering cycle—specifically, the temperature ramp-up rate, the peak temperature, and the holding time at that temperature.

Using an incorrect cycle for a specific type of zirconia can lead to suboptimal strength, poor esthetics, or internal stress.

Risks of Improper Sintering

An incomplete or improper sintering process can leave residual porosity, creating weak points that make the material prone to fracture under load.

Conversely, overheating can lead to excessive grain growth, which can also reduce the material's toughness and fracture resistance. Following the manufacturer's instructions is paramount.

Making the Right Choice for Your Goal

Achieving predictable and reliable results with zirconia requires careful attention to the sintering protocol, as different goals have different critical control points.

- If your primary focus is maximum clinical strength: Strict adherence to the manufacturer's validated sintering cycle is non-negotiable to achieve the specified flexural strength.

- If your primary focus is esthetics and translucency: Ensure the correct sintering program is used for the specific type of zirconia, as cycles for high-translucency materials often differ from those for high-strength ones.

- If your primary focus is accuracy of fit: Use high-quality zirconia beads and ensure the restoration is placed correctly in the crucible to allow for uniform, unrestricted shrinkage.

Ultimately, proper sintering is the final, critical manufacturing step that unlocks the full clinical potential of zirconia.

Summary Table:

| Sintering Stage | Key Process | Outcome |

|---|---|---|

| Green State | Milling of soft, porous zirconia | Easy shaping but low strength |

| Sintering | Heating to fuse particles | Eliminates pores, increases density |

| Final Form | Controlled cooling | High strength, hardness, and translucency |

Achieve precise and reliable zirconia sintering results with KINTEK.

Unlock the full clinical potential of your dental restorations. KINTEK specializes in high-performance lab furnaces and consumables, ensuring your zirconia reaches its optimal strength and aesthetics through precise temperature control and uniform heating.

Contact us today to find the perfect sintering solution for your laboratory needs and enhance your restoration quality. Get in touch via our Contact Form

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Dental Porcelain Sintering Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Spark Plasma Sintering Furnace SPS Furnace

People Also Ask

- What are the white spots on zirconia after sintering? A Guide to Diagnosing and Preventing Defects

- What is the sintering time for zirconia? A Guide to Precise Firing for Optimal Results

- Can you change the color of zirconia crowns? Understanding the Permanent Nature of Zirconia

- What is the price of zirconia sintering furnace? Invest in Precision, Not Just a Price Tag

- What is a dental oven? The Precision Furnace for Creating Strong, Aesthetic Dental Restorations