Fundamentals of TiN Film Deposition

Deposition Methods

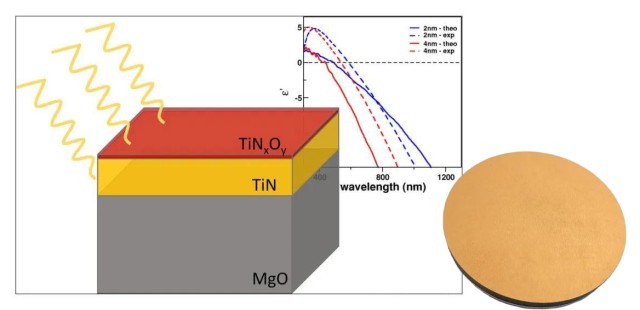

TiN films are commonly deposited using Physical Vapor Deposition (PVD) techniques, which require meticulous control over various conditions to achieve the desired film properties. Among the PVD methods, magnetron sputtering and evaporative deposition are particularly favored due to their ability to produce high-quality films with precise control over film thickness and composition.

Key PVD Techniques for TiN Film Deposition

-

Magnetron Sputtering: This method involves bombarding a target material with ions to eject atoms, which then condense onto a substrate. The use of a magnetic field enhances the efficiency of ion collection, making it a preferred method for depositing TiN films.

-

Evaporative Deposition: In this process, the TiN material is heated to a high vapor pressure, typically using electrical resistance heating in a high vacuum. The vaporized material then condenses onto the substrate, forming a thin film.

Additional Deposition Techniques

While magnetron sputtering and evaporative deposition are the most common, several other techniques can also be employed for TiN film deposition:

-

Cathodic Arc Deposition: A high-power electric arc is discharged at the target material, creating a highly ionized vapor that is deposited onto the workpiece.

-

Electron-Beam Physical Vapor Deposition (EBPVD): The material is heated to high vapor pressure by electron bombardment in a high vacuum, and the vapor is transported by diffusion to condense on the workpiece.

-

Pulsed Laser Deposition: A high-power laser ablates material from the target, generating a vapor that is deposited onto the substrate.

Each of these methods has its own set of advantages and challenges, but all require precise control over parameters such as temperature, pressure, and the composition of the deposition atmosphere to ensure the quality and uniformity of the TiN films.

Reaction Mechanism

The formation of Titanium Nitride (TiN) films is a complex process that involves the reaction between Titanium (Ti) and Nitrogen (N) atoms. This reaction is meticulously controlled by several critical factors, including temperature, atmosphere, and pressure.

Temperature plays a pivotal role in the activation of Ti and N atoms, enabling them to overcome the energy barrier required for chemical bonding. Typically, higher temperatures facilitate more efficient reactions, but excessive heat can also lead to unwanted side reactions and material degradation.

The atmosphere within the deposition chamber is another key determinant. A controlled nitrogen environment is essential to ensure that the Ti atoms can react with sufficient N atoms to form TiN. Variations in nitrogen concentration can significantly impact the film's stoichiometry and properties.

Pressure within the chamber also influences the reaction mechanism. Proper pressure control helps in maintaining the optimal mean free path of the reacting particles, ensuring that they collide with sufficient energy to form TiN. Deviations from the ideal pressure can result in either insufficient or excessive collisions, leading to non-uniform film growth and defects.

In summary, the synthesis of TiN films involves a delicate balance of temperature, atmosphere, and pressure, each of which must be precisely controlled to achieve high-quality film deposition.

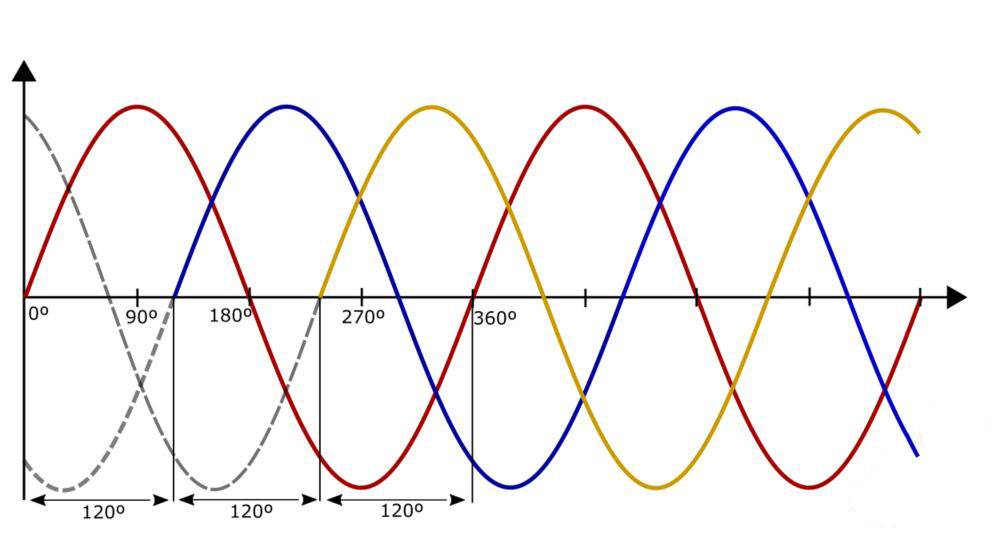

Characteristics of AC Power in Deposition

AC Power Cycles

AC power cycles between positive and negative states, significantly influencing ion bombardment and gas dissociation on the target surface. During the positive half-cycle, the target surface experiences increased ion bombardment, which can enhance the sputtering of titanium atoms. However, the negative half-cycle introduces challenges, particularly in the efficient dissociation of reactive gases like nitrogen. This alternating pattern can lead to uneven gas reactivity, affecting the overall uniformity and quality of the TiN film. The dynamic nature of AC power cycles necessitates careful monitoring and control to mitigate these effects and achieve optimal deposition conditions.

Current Stability Issues

Stabilizing AC power during the deposition of TiN films presents significant challenges, primarily due to the inherent fluctuations in current and voltage. These fluctuations can lead to erratic deposition rates, where the thickness and uniformity of the TiN film become inconsistent. Moreover, the efficiency of titanium (Ti) dissociation is compromised during negative voltage cycles, a critical phase in the formation of TiN. This reduced dissociation efficiency results in incomplete reactions, which in turn affects the overall quality and properties of the deposited film.

To address these issues, researchers have explored alternative power sources such as DC sputtering and pulsed DC technology. DC sputtering offers a more stable power supply, ensuring consistent deposition rates and improved film uniformity. Pulsed DC, on the other hand, provides high-energy pulses that can enhance the dissociation of Ti atoms, thereby optimizing the TiN film growth process. These methods not only mitigate the instabilities associated with AC power but also contribute to the development of higher-quality TiN films with fewer defects.

In summary, the difficulties in stabilizing AC power underscore the need for innovative solutions to ensure the precise control required for high-quality TiN film deposition.

TiN Film Growth Requirements

Ion Bombardment Needs

High-quality TiN film growth hinges on the delivery of sufficient ion bombardment energy, a critical factor that directly influences the structural integrity and mechanical properties of the deposited film. However, the inherent nature of AC power presents a significant challenge in this regard. Unlike DC power, which maintains a constant voltage and current, AC power cycles between positive and negative states. This cyclical variation can lead to inconsistent ion bombardment, as the energy delivered during the negative phase may not be sufficient to sustain the necessary reaction conditions for TiN formation.

To better understand this issue, consider the following key points:

-

Energy Delivery Variability: The alternating states of AC power result in fluctuations in the energy available for ion bombardment. During the positive phase, higher energy levels can be achieved, promoting efficient TiN growth. Conversely, the negative phase often delivers lower energy, which can disrupt the delicate balance required for high-quality film formation.

-

Impact on Reaction Rates: The inconsistent energy delivery of AC power can lead to varying reaction rates of Ti and N atoms. This variability can result in non-uniform film composition and structure, as the reaction conditions necessary for optimal TiN formation are not consistently met.

-

Comparison with DC Power: In contrast, DC power provides a stable and continuous energy source, which is crucial for maintaining consistent ion bombardment. This stability ensures that the TiN growth process remains uniform and efficient, leading to higher-quality films with fewer defects.

In summary, while AC power offers certain advantages in terms of equipment simplicity and cost, its inability to consistently deliver the necessary ion bombardment energy poses a significant limitation for high-quality TiN film growth. This challenge underscores the need for alternative power sources, such as DC or pulsed DC technologies, which can better meet the stringent requirements of TiN deposition.

Reaction Gas Activity

The alternating states of AC power can lead to uneven gas reactivity, significantly impacting the film's composition and growth rate. During the positive and negative cycles of AC power, the dissociation and reactivity of nitrogen gas, a crucial component for TiN film formation, can fluctuate. This fluctuation is due to the varying energy levels and ion bombardment intensities experienced during different phases of the AC cycle.

- Positive Cycle Effects: During the positive half of the AC cycle, higher energy levels can enhance the dissociation of nitrogen gas, leading to increased reactivity. However, this high energy can also cause sputtering of the Ti target, potentially altering the film's composition.

- Negative Cycle Effects: Conversely, the negative half of the cycle may not provide sufficient energy for effective nitrogen dissociation, resulting in lower reactivity. This imbalance can lead to non-uniform TiN film formation, where the film's thickness and composition vary across the substrate.

These uneven reactivity patterns can compromise the uniformity and quality of the TiN film, necessitating more stable power sources like DC or pulsed DC for optimal deposition conditions.

Experimental Observations

Growth Rate Analysis

Experiments conducted during the deposition of TiN films have consistently demonstrated that the growth rates achieved using DC power are significantly higher and more stable compared to those obtained with AC power. This observation is crucial for understanding the efficiency and reliability of the deposition process.

One of the primary reasons for this disparity lies in the nature of the power supply itself. DC power provides a continuous and stable flow of energy, which is essential for maintaining consistent ion bombardment and gas dissociation rates on the target surface. In contrast, AC power cycles between positive and negative states, leading to fluctuations in energy delivery and, consequently, in the growth rate of the TiN film.

| Parameter | DC Power | AC Power |

|---|---|---|

| Growth Rate | Higher and more stable | Lower and less stable |

| Energy Delivery | Continuous and stable | Cyclic and fluctuating |

| Ion Bombardment | Consistent | Inconsistent |

| Gas Dissociation | Efficient | Less efficient |

The table above summarizes the key differences in growth rate and process stability between DC and AC power. These differences are not merely quantitative but also qualitative, affecting the overall quality and uniformity of the TiN films.

In practical terms, the consistent growth rates achieved with DC power enable better control over the deposition process, leading to films with fewer defects and superior physical properties. This is particularly important in applications where high-quality TiN films are critical, such as in microelectronics and coatings for cutting tools.

Therefore, while AC power may be suitable for certain applications, DC power remains the preferred choice for achieving optimal growth rates and film quality in the deposition of TiN films.

Film Quality Comparison

When comparing the quality of TiN films grown under different power conditions, it becomes evident that Direct Current (DC) conditions yield superior results. TiN films produced under DC conditions exhibit enhanced physical properties and a significantly reduced defect density. This improvement can be attributed to the stable and consistent ion bombardment energy provided by DC power, which is crucial for the formation of high-quality films.

In contrast, Alternating Current (AC) power, which cycles between positive and negative states, often leads to instability in deposition rates and uneven gas reactivity. This variability can result in films with inferior mechanical properties and a higher incidence of defects. The alternating states of AC power can disrupt the delicate balance required for optimal TiN film growth, affecting both the film's composition and its overall structural integrity.

| Power Type | Physical Properties | Defect Density |

|---|---|---|

| DC Power | Enhanced | Reduced |

| AC Power | Inferior | Higher |

The experimental observations underscore the advantages of DC power in TiN film deposition. Studies have shown that DC-grown films not only have higher growth rates but also exhibit greater uniformity and fewer structural imperfections. These findings highlight the importance of power stability in achieving high-quality TiN films, making DC power a preferred choice for applications demanding robust and reliable coatings.

Solutions and Alternatives

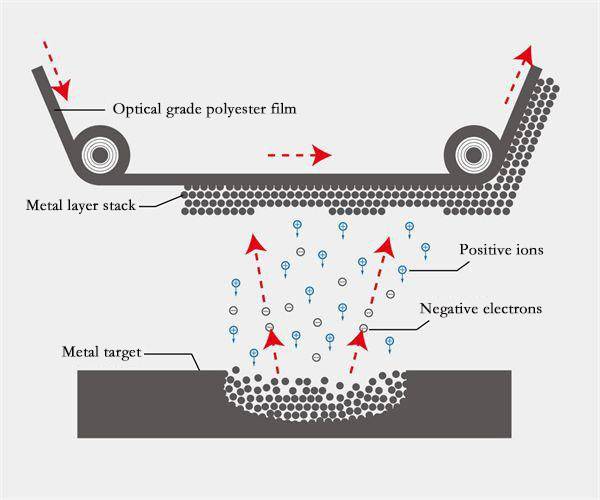

DC Magnetron Sputtering

DC magnetron sputtering is a robust technique for achieving stable deposition rates and film uniformity, making it a preferred method for thin-film deposition, especially for materials like Titanium Nitride (TiN). This process involves several critical steps that ensure the quality and consistency of the deposited film.

Firstly, the target material, which is the coating material in this case, is placed parallel to the substrate within a vacuum chamber. The chamber is then evacuated to a base pressure, typically removing moisture, air, hydrogen, and other gases, before being backfilled with a high-purity inert gas, often Argon. The use of Argon is advantageous due to its relatively high mass and its ability to transfer kinetic energy effectively during high-energy molecular collisions in the plasma.

Next, a DC electrical current, usually ranging from -2 to -5 kV, is applied to the target material, which acts as the cathode. This negative bias attracts positively charged ions from the plasma, which then bombard the target, causing atoms to be ejected and deposited onto the substrate. The substrate, which becomes the anode, is positively charged to facilitate this process.

The DC magnetron sputtering process operates at chamber pressures typically between 1 to 100 mTorr. This low-pressure environment ensures that the positively charged ions are accelerated towards the target material efficiently, leading to a high deposition rate. This technique is particularly effective for pure metal sputtering materials such as Iron (Fe), Copper (Cu), and Nickel (Ni), where high deposition rates are crucial.

In comparison to AC magnetron sputtering, DC sputtering offers several advantages. It provides a more stable and continuous ion bombardment, which is essential for high-quality TiN film growth. The direct current nature of the process ensures that the ions are consistently accelerated towards the target, resulting in uniform film deposition. This stability is particularly beneficial for large substrates, where uniformity and consistency are paramount.

Moreover, the ease of control and the relatively low cost of operation make DC magnetron sputtering an attractive option for industrial applications. The process is straightforward to implement and monitor, ensuring that the desired film properties are achieved consistently.

In summary, DC magnetron sputtering stands out as a reliable and efficient method for thin-film deposition, particularly for materials requiring high deposition rates and uniform film properties. Its ability to maintain stable conditions and its straightforward operation make it a superior choice over alternative methods, especially in the context of TiN film growth.

Pulsed DC Technology

Pulsed DC technology stands out as a superior method for TiN film deposition, particularly when compared to traditional AC power. This advanced technique leverages high-energy pulses to deliver precise and controlled energy to the target material, thereby enhancing the deposition process. The high-energy pulses ensure that the ions striking the target have sufficient energy to effectively dislodge and deposit Ti atoms, a critical factor in achieving high-quality TiN films.

One of the key advantages of pulsed DC is its ability to maintain stable deposition conditions. Unlike AC power, which oscillates between positive and negative states, pulsed DC provides a consistent and controlled environment. This stability is crucial for maintaining uniform ion bombardment and gas dissociation, leading to more consistent film growth rates and higher-quality films. The controlled environment minimizes fluctuations in the deposition process, which can otherwise lead to defects and inconsistencies in the final TiN film.

Moreover, pulsed DC technology allows for the optimization of film growth by fine-tuning the energy pulses. This fine-tuning can be adjusted based on the specific requirements of the TiN film, such as desired thickness, hardness, and other physical properties. The ability to customize the energy delivery ensures that the TiN film meets the desired specifications, making pulsed DC a versatile and powerful tool in the deposition of TiN films.

In summary, pulsed DC technology offers a robust solution for overcoming the challenges associated with AC power in TiN film deposition. By providing high-energy pulses and maintaining stable deposition conditions, pulsed DC optimizes film growth, resulting in high-quality TiN films with superior physical properties.

Optimizing Deposition Atmosphere

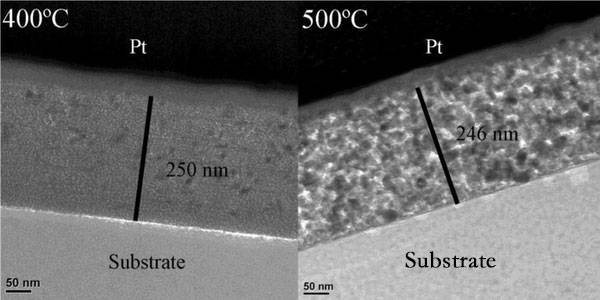

Optimizing the deposition atmosphere is crucial for enhancing the growth of TiN films. Key parameters such as the nitrogen flow rate and substrate temperature play significant roles in this process. The nitrogen flow rate directly influences the availability of nitrogen atoms, which are essential for the formation of TiN. A higher flow rate can lead to an excess of nitrogen, potentially causing the formation of unwanted compounds, while a lower flow rate may result in insufficient nitrogen for complete reaction with titanium. Therefore, achieving an optimal balance is essential for efficient film growth.

Substrate temperature is another critical factor that affects the quality and properties of the TiN film. Elevated temperatures can facilitate the diffusion of titanium and nitrogen atoms, promoting the formation of a denser and more uniform film. However, excessively high temperatures can lead to thermal degradation of the substrate material or the film itself. Conversely, low temperatures may hinder the diffusion process, resulting in a less dense and porous film. Thus, maintaining an appropriate substrate temperature is vital for obtaining high-quality TiN films.

In summary, fine-tuning the nitrogen flow rate and substrate temperature is indispensable for optimizing the deposition atmosphere, thereby enhancing the growth and quality of TiN films.

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth