Infrared Spectroscopy Methods

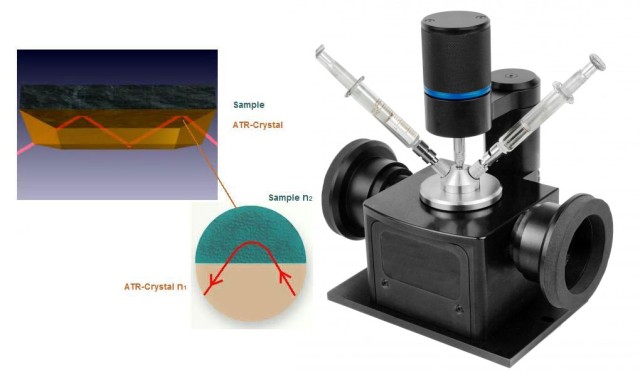

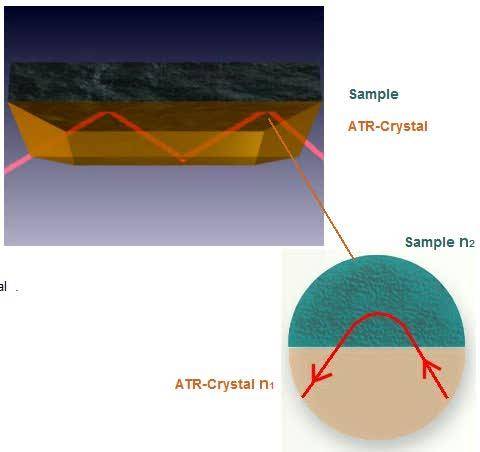

Attenuated Total Reflection (ATR) Method

The Attenuated Total Reflection (ATR) method represents a significant advancement in surface analysis technology, enabling direct sample analysis without the need for extensive preparation. This technique leverages infrared light to probe samples at micron depth levels, thereby circumventing the conventional requirements of potassium bromide dilution and tablet pressing.

In contrast to traditional methods that involve mixing powder samples with mediums like potassium bromide (KBr) or liquid paraffin, the ATR method allows for the direct measurement of powder samples. This is achieved by pressing the sample against a high-refractive-index prism, typically made of zinc selenide (ZnSe) or germanium (Ge), and measuring the infrared spectrum using light that undergoes total internal reflection within the prism.

The ATR method stands out as an exceptional technique for obtaining infrared information from the surface of powder samples. However, it necessitates careful consideration of the wavenumber dependency of absorption peak intensity and the potential for peak deformation towards a first-order differential form due to the anomalous dispersion of the refractive index, particularly in inorganic and other high-refractive-index samples.

Transmission Method

The transmission method is a traditional infrared sampling technique that is widely recognized and included in various standards. This method involves a series of meticulous steps to ensure accurate and reliable data collection. The process can be broken down into four primary stages: sample preparation, scanning background, scanning spectrum, and software analysis.

Sample preparation is the most critical and challenging step in the transmission method. It involves the use of potassium bromide (KBr), a substance known for its transparency to infrared light. The sample is typically mixed with KBr powder, which is then pressed into a transparent tablet form. This step requires precision and care to ensure that the sample is evenly dispersed within the KBr matrix, as any inconsistencies can lead to inaccurate spectral readings.

Once the sample preparation is complete, the next step is to scan the background. This involves measuring the infrared spectrum of the KBr tablet without the sample to establish a baseline. The background scan is essential for removing any inherent absorbance from the KBr itself, ensuring that the subsequent spectral data is solely representative of the sample.

Following the background scan, the actual sample spectrum is scanned. This step captures the unique infrared absorption patterns of the sample, which are then analyzed using specialized software. The software interprets these patterns to identify and quantify the chemical components present in the sample.

Each of these steps—sample preparation, scanning background, scanning spectrum, and software analysis—plays a crucial role in the overall accuracy and reliability of the transmission method. Despite its traditional nature, the transmission method remains a cornerstone in infrared spectroscopy due to its high sensitivity and the detailed insights it provides into sample composition.

Sample Preparation with Potassium Bromide

Preparation Steps

Preparation of potassium bromide (KBr) for infrared spectroscopy involves several meticulous steps to ensure the sample's integrity and the accuracy of the spectral data. Initially, the potassium bromide is ground to a fine powder, which is crucial for achieving homogeneous dispersion of the sample. This grinding process must be thorough to prevent any particle size inconsistencies that could lead to spectral noise or inaccuracies.

Once ground, the potassium bromide powder is spread evenly across a flat surface and baked. Baking is essential for removing any residual moisture, which can interfere with the infrared absorption spectrum. The dehydrated KBr is then used to prepare blank tablets. These blank tablets serve as a reference point, allowing for the precise measurement of the sample's absorption characteristics.

Next, the sample is carefully added to the ground potassium bromide. The mixture is thoroughly stirred to ensure even dispersion of the sample throughout the KBr matrix. This even distribution is critical for obtaining a clear and accurate infrared spectrum. Any clumps or uneven distribution could result in misleading spectral data.

Finally, the mixture is pressed into a transparent tablet under high pressure. The pressing process must be controlled to maintain consistent tablet thickness and density, which are key factors in the reproducibility of the infrared spectra. Proper pressing ensures that the tablet is transparent, allowing for clear transmission of infrared light and accurate spectral analysis.

These preparation steps are fundamental to the transmission method of infrared spectroscopy, ensuring that the sample is properly prepared for analysis and that the resulting spectra are reliable and reproducible.

Tablet Pressing Techniques

The process of tablet pressing involves several meticulous steps to ensure the formation of a uniform and transparent tablet. Initially, the ground potassium bromide powder is meticulously spread evenly between the molds of the tablet press. This step is crucial as it sets the foundation for the subsequent pressing process. The powder is then subjected to a controlled pressure, which compacts it into a preliminary form.

Following this, the sample material is introduced into the compacted powder. The inclusion of the sample requires precise handling to prevent any disruptions in the uniformity of the mixture. Once the sample is integrated, the mixture undergoes another round of pressing. This second pressing is typically more forceful than the initial one, ensuring that the sample is thoroughly embedded within the potassium bromide matrix. The application of high pressure in this final step is essential for achieving a solid, transparent tablet that is suitable for infrared spectroscopy analysis.

The tablet press operates on a two-step compression principle, utilizing both upper and lower punches within a die. The lower punch first creates a cavity in the die, into which the powder is introduced. The upper punch then descends, applying significant force to the powder, which bonds the granulated material into a cohesive tablet shape. The hydraulic pressure mechanism ensures that the force is uniformly distributed, allowing for adjustments in the applied pressure to accommodate different sample requirements.

During the pressing process, the raw materials are carefully loaded into the die and subjected to the pressing plate at the lower part of the die. This gradual deformation of the raw materials results in the formation of the desired tablet. The compression mold, which typically consists of a pair of upper and lower molds, allows for manual adjustments to the distance between the molds, ensuring adaptability to various pressing needs. The upper mold is fixed on a bracket, while the lower mold is secured on a pressure plate, facilitating consistent contact between the molds during the pressing action.

In summary, the tablet pressing techniques are a blend of precision and force, meticulously designed to create transparent tablets that are ideal for infrared spectroscopy. The process not only ensures the uniformity and integrity of the sample but also adheres to stringent quality control measures, essential for accurate spectroscopic analysis.

Best Practices and Notes

To ensure accurate and reliable results in infrared spectroscopy, several best practices and notes should be adhered to during the sample preparation process.

First and foremost, measuring the background with air before analyzing the sample is crucial. This step helps to eliminate any potential interference from the environment, thereby ensuring that the subsequent measurements are not skewed by external factors.

Using high-quality, spectrally pure KBr is another critical aspect. The purity of the potassium bromide directly impacts the clarity and accuracy of the spectrum. Any impurities in the KBr can introduce noise or artifacts in the data, leading to erroneous interpretations.

Consistency in the preparation process is key. This includes consistent grinding of the potassium bromide, which ensures that the particles are of uniform size. Additionally, maintaining consistent thickness and pressure during the tablet preparation is essential. Variations in these parameters can lead to differences in the optical path length, affecting the intensity and resolution of the spectrum.

By following these best practices, the accuracy and reliability of the infrared spectroscopy results can be significantly enhanced, providing more precise and meaningful data for analysis.

Related Products

- No Demolding Lab Infrared Press Mold for Laboratory Applications

- Lab Infrared Press Mold

- kbr pellet press 2t

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- XRF & KBR plastic ring lab Powder Pellet Pressing Mold for FTIR