Introduction to FTIR Sample Preparation

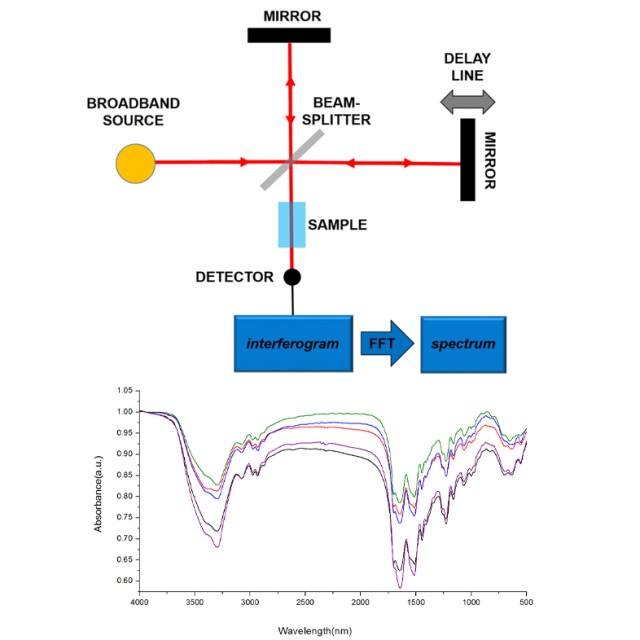

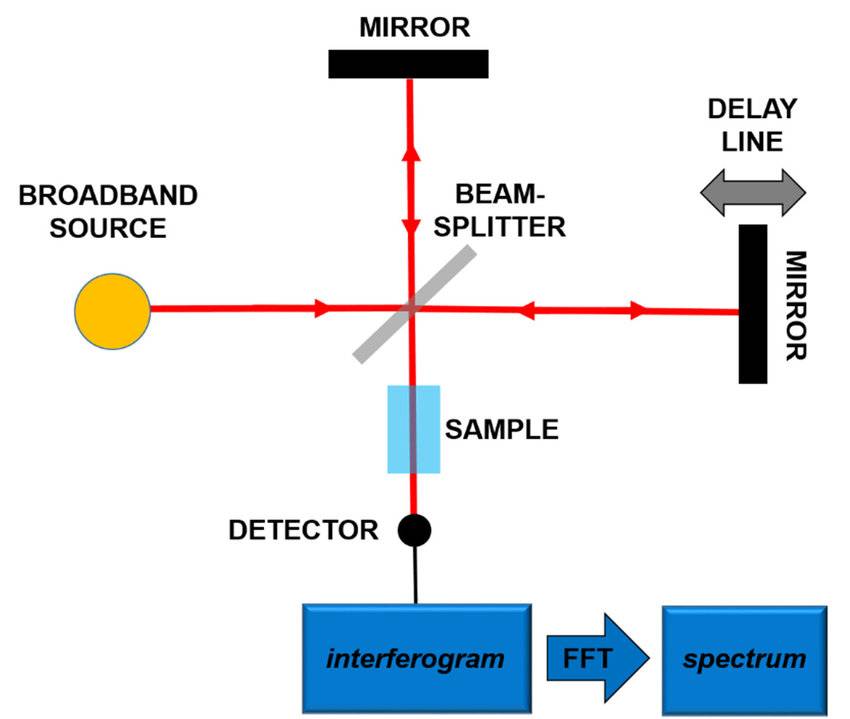

Fourier Transform Infrared (FTIR) spectroscopy is a powerful analytical technique that can be used to identify and quantify the chemical components of a sample. However, to obtain accurate and reliable results, it is crucial to prepare the sample appropriately. The sample preparation process involves transforming the sample into a form that can be analyzed by the FTIR instrument. This process is critical because it can affect the sensitivity and accuracy of the analysis. Proper FTIR sample preparation involves selecting the right method, considering the sample's physical and chemical properties, and ensuring that the sample is homogenous.

Table of Contents

Importance of Precise Sample Preparation

Precise sample preparation is a critical aspect of FTIR analysis, as it has a significant impact on the accuracy and reliability of the results. Inconsistencies in the sample preparation process can lead to incorrect measurements and misinterpretation of data. In this section, we will discuss the importance of precise sample preparation in FTIR analysis and how the FTIR pellet press can help achieve this.

Sample Uniformity

One of the essential requirements in FTIR analysis is the creation of a uniform and homogeneous sample. The FTIR pellet press is designed to compress a small amount of sample material into a uniform pellet that can be easily analyzed. The use of a pellet press ensures that the sample is evenly distributed, free of air bubbles, and has a smooth surface for optimal measurement accuracy.

Representativeness

The sample used in FTIR analysis must be representative of the entire material. The use of a pellet press eliminates the potential for variability and ensures that the sample is representative. This is particularly important when analyzing samples with complex compositions, such as polymers or mixtures, where it is crucial to obtain a representative sample.

Accuracy and Reliability

Precise sample preparation is essential for accurate and reliable FTIR analysis. The use of a pellet press ensures that the sample is uniform, representative, and accurately analyzed. Any inconsistency in the sample preparation can lead to incorrect results and misinterpretation of data.

Compatibility

The FTIR pellet press is also useful when analyzing small samples that cannot be analyzed directly, or when analyzing samples that are not compatible with other sample preparation techniques. The pellet press can help in achieving precise sample preparation, even for the most challenging samples.

Time and Cost-Efficient

The FTIR pellet press is a time and cost-efficient tool for precise sample preparation in FTIR analysis. It eliminates the need for complex and time-consuming sample preparation techniques, making it an essential tool for researchers and analysts in various fields.

In conclusion, precise sample preparation is essential for accurate and reliable FTIR analysis. The use of an FTIR pellet press is an excellent solution for achieving uniform, representative, and accurately analyzed samples. The pellet press ensures that the sample is free of air bubbles, evenly distributed, and has a smooth surface for optimal measurement accuracy.

Pelletizing Process for FTIR Analysis

The accuracy of FTIR analysis heavily relies on the quality of the sample preparation process, which involves converting a sample into a pellet form. The FTIR pellet press is the ultimate solution for precise sample preparation, allowing for the production of uniform and reproducible pellets.

The Purpose of Pelletizing

The goal of pelletizing for FTIR analysis is to create a thin, transparent pellet which contains the sample you are interested in characterizing held in an IR transparent medium (typically KBr) known as a KBr pellet. FTIR is a very sensitive technique, so you only need a few mg of your sample and the vast majority of your pellet is KBr (or another IR-transparent material).

Sample Preparation

To make a pellet, the sample is mixed with the potassium bromide and ground to a fine powder using a pestle and mortar. Mixing ratio of sample to binder is typically 10(sample) : 1(binder) or 10 : 2. It is necessary to determine the purity of the binder as it is necessary to select a binder that does not include the elements to be analyzed.

Pellet Press Die Set

A Pellet Press Die Set of the diameter you need – these can be selected from standard die sets or low profile die sets. Pellets for FTIR are typically required to be within 3 mm up to 13 mm, the exact diameter will depend on the manufacturer of your FTIR equipment. The type of die set to be used depends on the characteristics of the sample.

Hydraulic Press

The pelletizing process involves compressing a small amount of sample material into a thin, flat disc using a hydraulic press. Hydraulic presses – also known as Bramah presses – are used to produce solid samples for analysis by infra-red spectroscopy. The hydraulic press makes producing these discs quick, easy and repeatable, for reliable and efficient test conditions.

Procedure

The Pellet Press Die Set is cleaned with chloroform or lubricant spray thoroughly to get rid of any dirt and dried with tissue. The mortar and pestle are also cleaned with chloroform or acetone thoroughly to get rid of any dirt and dried with tissue. A speck of sample is transferred into the mortar. Scoop out dry KBr into the mortar and grind it using the pestle. Depending on the thickness of the pellet to be achieved, the amount of powder is put into the cavity. The Pellet Press is fixed together by inserting the die into the cavity, and the ground sample mix is transferred into the cavity using a metal spatula. The bolt press is inserted and rotated into the cavity to distribute the particles. The whole die set is transferred to the hydraulic pellet press and rotated to secure it tightly. The valve of the hydraulic press is then closed, and the lever is pulled to put pressure until the handle becomes tight. To release the die, first, the pressure is loosened, then the upper wheel of the press is moved up, and then the die is taken out. The bottom plunger is taken out, and the die is placed in the ejector, after which pressure is applied to release the pellet from the die.

The FTIR pellet press is designed to work with a variety of sample materials, including solids, liquids, and powders. It is a versatile and user-friendly tool that ensures the accuracy and reliability of FTIR analysis. The pellet press is also designed to prevent contamination, ensuring that the sample remains pure throughout the preparation process. With the FTIR pellet press, laboratory technicians can produce consistent and high-quality pellets, leading to more accurate and reliable analysis results.

Key Considerations for FTIR Pelletizing

Sample Preparation Method

The first key consideration for FTIR pelletizing is selecting the appropriate sample preparation method. The nature of the sample being analyzed should be taken into account when choosing the sample preparation method. It is essential to ensure that the method used provides a representative sample that accurately reflects the composition and properties of the material being analyzed.

Choosing the Right Pellet Press

Choosing the right pellet press is another essential consideration for FTIR pelletizing. The size and shape of the pellets required, the pressure range, and the ease of operation should be considered when selecting a pellet press. It is essential to ensure that the pellet press meets the specific requirements of the sample being analyzed.

Quality Control

Quality control is crucial to ensure that the pellets produced are consistent in size and thickness. The use of a reliable and accurate pellet press is necessary to produce pellets that are suitable for FTIR analysis. Proper cleaning and maintenance of the pellet press are necessary to ensure consistent results. Regular calibration of the pellet press is essential to ensure that it is operating within the required parameters.

Particle Size

Producing pressed pellets requires accuracy and specific measurements, and pelletizing works well when samples are ground to a particle size of <50µm. Working with small particle sizes is essential because this impacts how well the sample binds together under pressure, which impacts the analytical results.

Pressure

After the sample has been mixed with the binding agent, it is added to a die to be pressed. The sample is usually pressed with a hydraulic sample press, and the pressure applied through this instrument needs to be enough for the binder to recrystallize and for the sample to be completely compressed. Most samples will require pressing for 1-2 minutes, under 25-35T of pressure to ensure no void spaces are present in the pellet.

Thickness

Aside from particle size, the thickness of pressed pellets is also crucial for the effective analysis of a sample. If a sample is too thick, the X-rays will not be able to penetrate it up to a certain point. Because FTIR analysis relies on transmitted infrared radiation reaching the detector, the sample must have a uniform thickness to ensure accurate results.

In conclusion, FTIR pelletizing is a critical step in FTIR spectroscopy analysis. The key considerations for FTIR pelletizing include selecting the appropriate sample preparation method, choosing the right pellet press, and ensuring the quality of the pellets produced. Proper control of particle size, pressure, and thickness are important to ensure consistent and accurate results. FTIR Pellet Press is an indispensable tool for researchers, scientists, and professionals in the field of analytical chemistry to produce high-quality pellets that are suitable for FTIR analysis.

Advantages of Using FTIR Pellet Press

FTIR pellet press is an essential tool for any laboratory that uses FTIR spectroscopy for the analysis of samples. Here are some of the advantages of using an FTIR pellet press:

Reproducibility

One of the significant advantages of using an FTIR pellet press is the reproducibility of the sample preparation process. The FTIR pellet press ensures that the sample is uniformly prepared, which is essential for obtaining reliable and accurate results. The device applies high pressure and temperature to the sample to create a solid pellet with a uniform thickness for analysis. This technique eliminates the need for expensive and time-consuming sample preparation techniques such as KBr powder pressing, making it more cost-effective.

Ease of Handling

Another advantage of using an FTIR pellet press is that it provides a clean and easy way of handling the sample. The pellets are easy to handle, store, and transport, which is particularly important for samples that are sensitive to air and moisture. The FTIR pellet press can also handle a wide range of sample types, including powders, liquids, and gels.

Versatility

The FTIR pellet press can be used for the identification and characterization of various compounds, including solids, liquids, and gases, making it a versatile tool in many industries such as pharmaceuticals, food, chemical, and material science. It ensures the reproducibility of the sample preparation process, which is essential for obtaining reliable and accurate results.

Time-Saving

Using an FTIR pellet press is also a time-saving technique as it eliminates the need for expensive and time-consuming sample preparation techniques such as KBr powder pressing. The device applies high pressure and temperature to the sample to create a solid pellet with a uniform thickness for analysis. This technique ensures that the sample is uniformly prepared, which is essential for obtaining reliable and accurate results.

Clean and Safe

Using an FTIR pellet press also ensures that the sample is clean and safe for handling. The pellets are easy to handle, store, and transport, which is particularly important for samples that are sensitive to air and moisture. The device applies high pressure and temperature to the sample to create a solid pellet with a uniform thickness for analysis, ensuring that the sample is uniformly prepared.

In conclusion, the advantages of using an FTIR pellet press are numerous. It ensures the reproducibility of the sample preparation process, which is essential for obtaining reliable and accurate results. It is a time-saving technique that eliminates the need for expensive and time-consuming sample preparation techniques such as KBr powder pressing. The pellets are easy to handle, store, and transport, which is particularly important for samples that are sensitive to air and moisture. The FTIR pellet press is a versatile tool that can be used for the identification and characterization of various compounds, including solids, liquids, and gases.

Conclusion: FTIR Pellet Press for Accurate Sample Analysis

In conclusion, the FTIR pellet press offers a reliable and efficient solution for precise sample preparation. Through the pelletizing process, a homogeneous and stable sample is produced, which is essential for accurate FTIR analysis. The key considerations for successful pelletizing include selecting the appropriate sample preparation method, using the correct pressure and temperature conditions, and ensuring the sample is evenly distributed within the pellet. By using an FTIR pellet press, the analysis time is reduced, and the resulting spectra are of high quality, providing reliable and accurate results. Overall, the FTIR pellet press is an essential tool for achieving reliable and consistent sample analysis.

Related Products

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Pellet Press for XRF KBR FTIR Lab Applications

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- kbr pellet press 2t

Related Articles

- Automated laboratory XRF and KBR pellet press operating procedures

- Why Your Sample Prep Fails: The Hidden Flaw in Your Hydraulic Press

- What is xrf analysis and how to making pressed xrf pellets

- Understanding Cold Isostatic Pressing (CIP) and Its Advantages

- Operating of Automatic Lab xrf Pellet Press