Introduction to FTIR Pellet Press

FTIR (Fourier Transform Infrared) spectroscopy is a powerful analytical technique used to identify and quantify the chemical composition of materials. Sample preparation is essential for obtaining reliable results in FTIR analysis. One of the most commonly used techniques for sample preparation is the FTIR pellet press. This technique involves pressing powdered samples into a pellet using a hydraulic press. The resulting pellet is highly homogeneous and transparent, allowing for more accurate and reproducible FTIR spectra. FTIR pellet presses are available in a range of sizes and designs, from mini presses suitable for small laboratories to full-sized presses for high-throughput analysis.

Table of Contents

Importance of Sample Preparation

Sample preparation is a crucial step in any laboratory analysis, especially in Fourier transform infrared (FTIR) spectroscopy. The quality of the sample preparation greatly affects the accuracy and reliability of the results. Poor sample preparation can lead to erroneous results, which can result in faulty conclusions and wasted resources.

Ensuring Representative Sample

Sample preparation involves a series of steps that must be carefully executed to ensure that the sample is representative of the original material. It is essential to ensure that the sample is homogenous and free from any contamination. The sample should be collected in a way that it represents the entire material, and the results obtained from the sample can be generalized for the entire material.

Role of FTIR Pellet Press

FTIR pellet presses help to streamline this process, minimizing human error and reducing the time and effort required for sample preparation. The device is designed to simplify the process of making pellets from powdered or granular samples, which can then be easily analyzed using FTIR spectroscopy. The process is quick and efficient, and the resulting pellets are highly reproducible, ensuring accurate and consistent results.

Importance of Accurate Sample Preparation

The importance of sample preparation cannot be overstated. It is one of the critical factors that affect the accuracy and reliability of the results obtained from a laboratory analysis. Proper sample preparation ensures that the sample is representative of the original material and free from any contamination. It also helps to reduce errors and ensure that the results obtained are consistent and reproducible.

Impact of Poor Sample Preparation

Poor sample preparation can lead to erroneous results, which can result in faulty conclusions and wasted resources. The results obtained from a poorly prepared sample may not be reliable and can lead to incorrect analysis and decision-making. It is, therefore, essential to ensure that the sample preparation process is executed correctly to obtain accurate and reliable results.

In conclusion, sample preparation is a crucial step in any laboratory analysis, and the quality of the sample preparation greatly affects the accuracy and reliability of the results. FTIR pellet presses provide a simple and effective solution for sample preparation in FTIR spectroscopy, ensuring that the sample is representative of the original material, free from contamination, and highly reproducible.

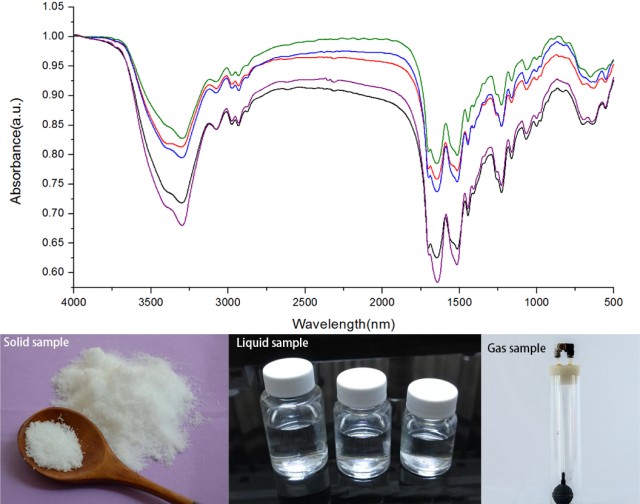

Pressing Powder Samples for FTIR

FTIR (Fourier Transform Infrared) spectroscopy is a widely used analytical technique in the field of chemistry. The preparation of samples for FTIR analysis often involves making pellets from powders. This process can be time-consuming and requires a high level of skill to produce consistent results. However, with the use of an FTIR pellet press, sample preparation can be simplified and made more efficient.

Equipment Needed for Pressing Powder Samples

To press powder samples, you will need a pellet press die set of the diameter you need for your sample, a pestle and mortar, and KBr powder. If you are using a low-profile die set, you will not need a release ring.

Grinding and Mixing the Sample Powder

Take a small amount of your sample powder and grind it in the pestle and mortar. For a ½ inch (12.7 mm) diameter sample, take around 1-2 mg. If you are making a smaller diameter pellet, use less powder. Add KBr powder and grind briefly to mix. Over grinding will increase surface area and therefore moisture absorption.

Adding Sample Mixture to the Die

Put the pellet press die sleeve onto the base plate, add the sample + KBr mixture and put the plunger on top. Press with force per unit area of around 8,000 to 10,000 psi (55-69 MPa). The force applied will depend on the diameter of your pellet.

Releasing the Pellet

Remove the base plate, turn the die sleeve over, and add the release ring to the top. Press the pellet through to release it. If you are using a low-profile die set, you can just press against the inbuilt prongs.

Checking the Pellet

The resultant pellet you are aiming for is around 2mm thick and clear/transparent. If your pellet is too thick or not transparent, you may need to adjust the amount of powder being used. Depending on your FTIR equipment, you may be able to examine your pellet while still in the sleeve.

In conclusion, pressing powder samples for FTIR analysis can be simplified and made more efficient with the use of an FTIR pellet press. By following the steps above, you can create uniform pellets for FTIR analysis with ease.

Hydraulic Mini Press vs Full-sized Press

FTIR spectroscopy is a powerful analytical technique used in various industries for identifying and characterizing chemical compounds. However, sample preparation is a critical step that can affect the accuracy and reproducibility of the results. One popular method for preparing solid samples for FTIR analysis is by using a pellet press. Two common types of pellet presses are the hydraulic mini press and the full-sized press.

Hydraulic Mini Press

A hydraulic mini press is a smaller, more affordable, and lightweight version of a full-sized hydraulic press. It is suitable for preparing small batches of samples and can produce pellets with a diameter of up to 13mm and a thickness of up to 3mm. It is commonly found in pharmaceutical labs, polymer testing labs, and undergraduate chemistry labs, where pressing pellets for FTIR is commonplace. The mini press can accurately apply 2 tons of pressure, just by turning a handle, and features a pressure gauge. This ensures that the same load is always applied, making sample production far more repeatable.

Full-sized Press

The full-sized press is larger and more expensive but can produce larger pellets with a diameter of up to 32mm and a thickness of up to 6mm. It is ideal for laboratories that need to prepare a large number of samples on a regular basis. Standard-sized hydraulic presses are manually hand-pumped and require more physical effort compared to a mini press. However, they can produce larger samples and are capable of applying greater pressure loads.

Choosing the Right Press

The choice of which press to use depends on the laboratory's needs and budget. If the laboratory needs to prepare small batches of samples, a hydraulic mini press is a great option. It is more affordable, lightweight, and suitable for producing smaller pellets. On the other hand, if the laboratory needs to prepare a large number of samples on a regular basis, a full-sized press is a better option. It can produce larger pellets and is capable of applying greater pressure loads.

Conclusion

Both the hydraulic mini press and full-sized press can simplify sample preparation for FTIR analysis and provide accurate and reproducible results. It is essential to choose the right press based on the laboratory's needs and budget. With the right press, sample preparation can be completed quickly, easily, and efficiently, providing reliable and efficient test conditions.

Sample Preparation for XRF Analysis

X-ray Fluorescence spectroscopy (XRF) is widely used for the quality control of raw materials and finished products in many industries such as mining, industrial minerals, and cement. However, sample preparation is the most significant source of error in the analysis of materials by XRF. In this section, we will discuss the process of preparing samples for XRF analysis by making pressed pellets.

Grinding the Sample

The first step in preparing samples for XRF analysis is to grind the sample to a fine particle size. The sample should be ground to a particle size of < 75µm, but < 50µm is ideal. Depending on the sample type and volume, this can usually be accomplished with a few minutes of grinding with a typical ring and puck pulverizing mill. A small particle size is an important factor in producing pellets that provide the best analytical results because it affects how the sample will compress and bind together when pressed.

Mixing with Binder

The next step is to mix the powdered sample with x-ray powder or a similar binder. The binder helps to hold the sample together to produce a homogenous, flat, and uniform surface for accurate analysis. The choice of binder, the dilution ratio, and the amount of pressure applied to the sample are all important factors in producing pellets that provide the best analytical results.

Inserting the Mixture into a Pellet Die

Once the sample has been mixed with the binder, the mixture is then poured into a pellet die. Common sizes for round XRF pellets are 32 mm or 40 mm diameter. Standard XRF dies require user intervention for the pellet ejection step. For higher sample throughput labs, an automated loading system or a tool that can be used to load the sample is available.

Compressing the Die

The final step is to compress the die at pressures between 15 and 40 tons. The resulting pellet or tablet is then ready for analysis. The pellet press is particularly useful in preparing samples for XRF analysis as it ensures that the sample surface is uniform, reducing the risk of errors in analysis. In situations where many samples are to be prepared for analysis at a later time, the rings offer good protection for the sample.

Advantages of Using Pellets for XRF

Pressed cement samples show a higher signal-to-noise ratio, which allows the detection of the lightest elements compared to its loose powder form. When quantifying the elemental composition, significant discrepancies are observed between the expected values and the loose powder samples. When the same batch of cement is used to prepare a pressed pellet, these discrepancies disappear. Moreover, grinding of samples to a very fine particle size and then compressing into a smooth and flat XRF pellet reduces background scattering and improves the detection of emissions.

In conclusion, preparing high-quality XRF pellets is essential for the analysis of samples like cement or similar. By following these basic points, you can ensure that your X-Ray Fluorescence analysis gets off to a smooth, homogeneous start.

Five Important Considerations for Sample Preparation

Sample preparation is a critical step in Fourier Transform Infrared (FTIR) spectroscopy that involves the preparation of a sample for analysis by making a pellet from a ground sample. FTIR pellet presses are used to simplify this process, making it quick, efficient, and reliable. However, before using this equipment, there are five important considerations that need to be taken into account.

Particle Size and Homogeneity

The first consideration is to ensure that the sample is ground correctly, as the particle size and homogeneity of the sample can affect the quality of the pellet. The particle size of the sample must be uniform and as small as possible to produce the best results. The use of sieves can help to ensure a consistent particle size.

Choose the Right Binder

The second consideration is to choose the right binder, which can be a challenge for some samples. The binder should be able to hold the sample together without interfering with the analysis. Common binders include polyvinyl alcohol (PVA), polyethylene glycol (PEG), and potassium bromide (KBr).

Amount of Pressure

The third consideration is to use the right amount of pressure, as applying too much pressure can cause the pellet to crack, while too little pressure can result in a low-quality pellet. The appropriate pressure varies depending on the sample type, the amount of sample, and the pellet size.

Pellet Die Size

The fourth consideration is to select the appropriate pellet die size, which is determined by the sample quantity and the type of analysis required. The size of the pellet die should be chosen based on the volume of the sample and the desired thickness of the pellet.

Cleaning and Maintenance

Lastly, it is important to consider the cleaning and maintenance of the FTIR pellet press, which can significantly affect the longevity and performance of the equipment. Regular cleaning and maintenance can help to prevent contamination and ensure accurate and reliable results.

In conclusion, sample preparation with an FTIR pellet press can be simplified, optimized, and produce accurate and reliable results by taking these five considerations into account. Proper sample preparation is essential for producing high-quality analytical results.

Related Products

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

- Laboratory Hydraulic Pellet Press for XRF KBR FTIR Lab Applications

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box