Yes, induction stoves are significantly more environmentally friendly than their gas or traditional electric counterparts. This is due to two core factors: their unmatched energy efficiency, which reduces overall energy consumption, and their complete elimination of the harmful indoor air pollutants produced by burning natural gas.

The environmental case for induction cooking is built on superior efficiency and improved health. While its ultimate carbon footprint depends on the source of your electricity, it is the only cooking technology that offers a clear path to a zero-emission, healthier home.

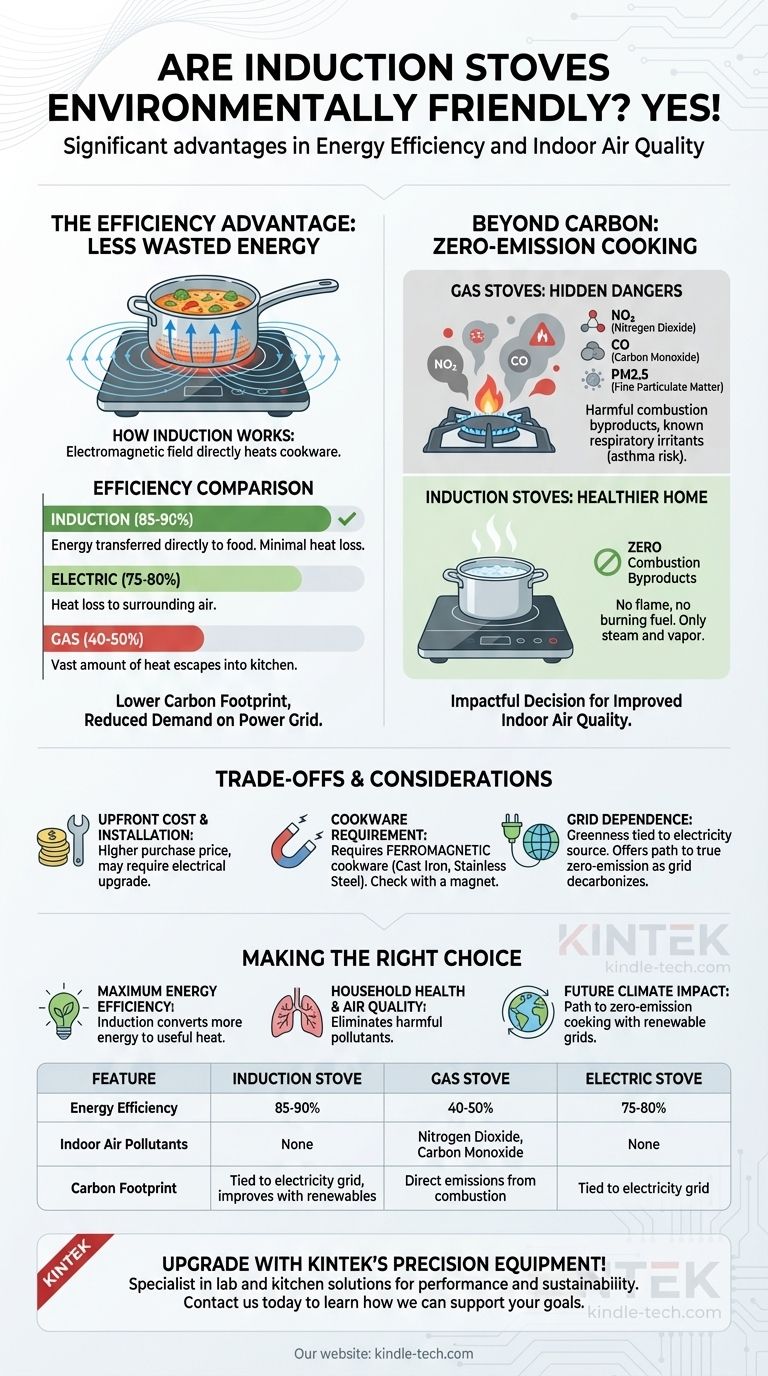

The Efficiency Advantage: Where Induction Excels

The primary environmental benefit of induction technology is its fundamental efficiency. It simply wastes less energy than any other cooking method.

How Induction Technology Works

Unlike conventional stoves, induction cooktops do not create heat themselves. Instead, they use a powerful electromagnetic field to directly heat the cookware. This means the pot or pan becomes the heat source, not the stovetop surface.

Efficiency by the Numbers

This direct-heating method results in a dramatic difference in energy efficiency:

- Induction: Approximately 85-90% of the energy is transferred directly to the food.

- Electric (Coil/Ceramic): About 75-80% efficient, with significant heat lost from the glowing element to the surrounding air.

- Gas: Only 40-50% efficient, as a vast amount of heat escapes around the sides of the pot and into your kitchen.

Less Wasted Energy, Less Impact

This efficiency gap means that for the same cooking task, an induction stove consumes significantly less energy. This translates directly to a lower carbon footprint and reduced demand on the power grid.

Beyond Carbon: The Critical Impact on Indoor Air Quality

An often-overlooked environmental factor is the quality of the air inside your home. Here, the difference between induction and gas is stark.

The Hidden Dangers of Gas Stoves

Burning natural gas releases several harmful byproducts directly into your home. These include nitrogen dioxide (NO₂), carbon monoxide (CO), and fine particulate matter (PM2.5), all of which are known respiratory irritants linked to increased rates of asthma, especially in children.

Induction's Zero-Emission Cooking

Induction stoves produce zero combustion byproducts. There is no flame and no burning fuel. The only emissions are the steam and vapor coming from the food you are cooking, which is easily managed with proper ventilation.

A Healthier Home Environment

Choosing induction over gas is one of the most impactful decisions you can make to improve your family's daily exposure to airborne pollutants, creating a healthier living space.

Understanding the Trade-offs and Considerations

While the benefits are clear, a complete analysis requires acknowledging the practical considerations of switching to induction.

Upfront Cost and Installation

Induction cooktops generally have a higher purchase price than comparable gas or electric models. Depending on your home's wiring, you may also need an electrician to ensure you have the proper electrical circuit.

The Cookware Requirement

Induction technology requires ferromagnetic cookware. This means pots and pans must contain iron to work. Cast iron and most stainless steel pans are compatible, but aluminum, copper, and glass cookware are not. A simple test is to see if a magnet sticks to the bottom of your pot.

Dependence on the Electrical Grid

The "greenness" of your induction stove is directly tied to the source of your electricity. If your grid is powered heavily by fossil fuels, your cooking will still have an upstream carbon footprint. However, this is a crucial distinction: an induction stove becomes greener as the grid becomes greener, offering a path to true zero-emission cooking that a gas stove can never provide.

Making the Right Choice for Your Goal

Ultimately, the decision rests on your priorities. An induction stove represents a forward-looking investment in efficiency, health, and decarbonization.

- If your primary focus is maximum energy efficiency and lower utility bills: Induction is the undisputed leader, converting far more energy into useful heat than any alternative.

- If your primary focus is household health and air quality: Induction is the superior choice, as it completely eliminates the harmful indoor pollutants released by gas stoves.

- If your primary focus is future climate impact: Induction provides the only pathway to zero-emission cooking by allowing your kitchen to run on an increasingly renewable electrical grid.

By choosing induction, you are investing in a technology that is not only better for the environment today but is perfectly positioned for the cleaner energy systems of tomorrow.

Summary Table:

| Feature | Induction Stove | Gas Stove | Electric Stove |

|---|---|---|---|

| Energy Efficiency | 85-90% | 40-50% | 75-80% |

| Indoor Air Pollutants | None | Nitrogen Dioxide, Carbon Monoxide | None |

| Carbon Footprint | Tied to electricity grid, improves with renewables | Direct emissions from gas combustion | Tied to electricity grid |

Upgrade your lab or kitchen with KINTEK's precision equipment! As a specialist in lab equipment and consumables, we understand the importance of efficiency and safety. Whether you're outfitting a research facility or a commercial kitchen, our solutions are designed to meet your needs for performance and sustainability. Contact us today to learn how we can support your goals with reliable, high-quality products.

Visual Guide

Related Products

- Three-dimensional electromagnetic sieving instrument

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Ultra-Vacuum Electrode Feedthrough Connector Flange Power Electrode Lead for High-Precision Applications

- Automatic Laboratory Heat Press Machine

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

People Also Ask

- What is powder sieving? A Guide to Accurate Particle Size Separation

- What is the operating procedure of a sieve shaker? Master Accurate Particle Size Analysis

- What are the disadvantages of sieve machine? Key Limitations in Particle Size Analysis

- What are the different types of sieving machines? Choose the Right Motion for Your Material

- What does a vibrating sieve do? Automate Particle Size Analysis for Accurate Results