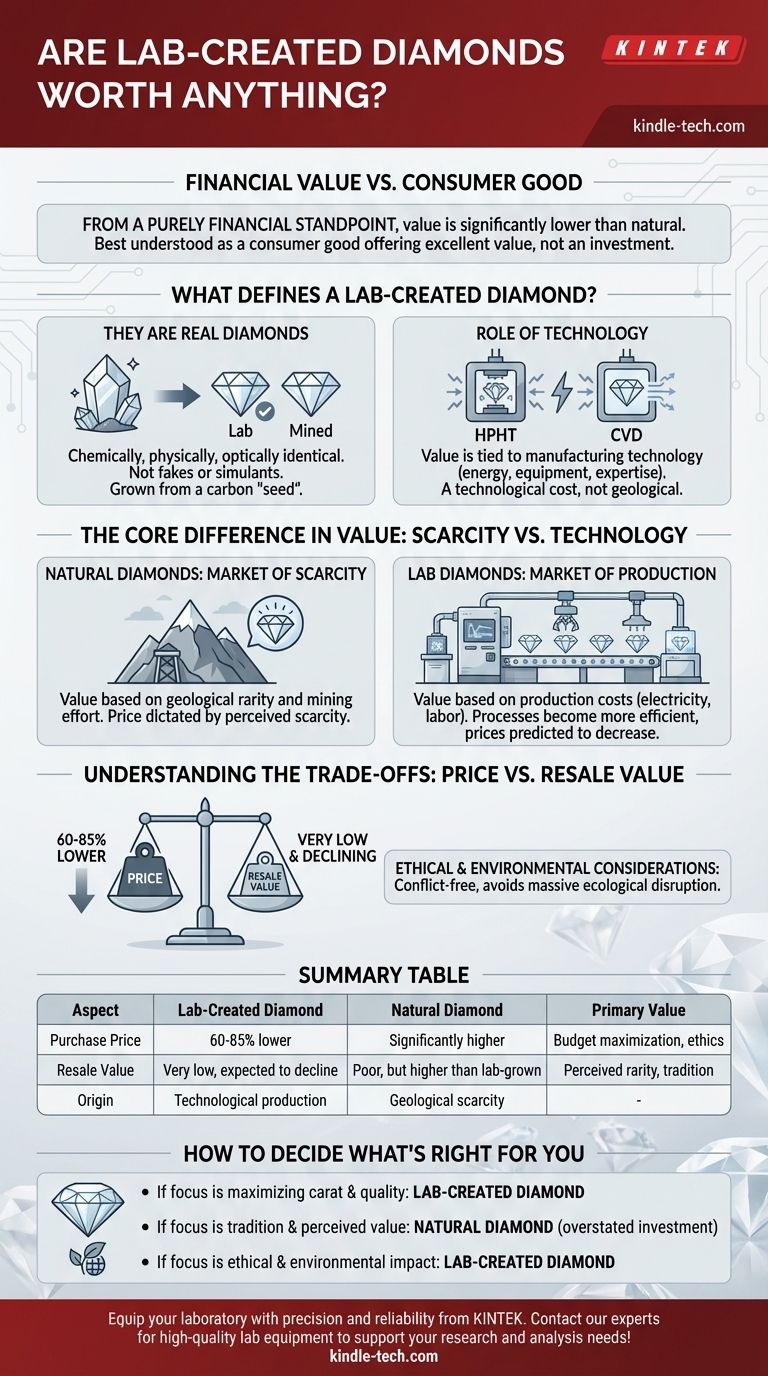

From a purely financial standpoint, lab-created diamonds have a monetary value that is significantly lower than natural diamonds of the same size and quality. While they are real diamonds in every physical and chemical sense, they are best understood as a consumer good that offers excellent value for the price, not as a financial asset intended to hold or increase in value over time.

The "worth" of a lab diamond is not in its potential for resale, but in its ability to provide a larger, higher-quality stone for a significantly lower initial cost compared to a mined diamond. The choice between lab and natural is a choice between maximizing your budget and adhering to the traditional market of perceived rarity.

What Defines a Lab-Created Diamond?

To understand a lab diamond's value, you must first understand what it is. The distinction between a lab-grown and a natural diamond is not one of quality or appearance, but of origin.

They Are Real Diamonds

Lab-created diamonds are not fakes or simulants like cubic zirconia. They possess the exact same chemical, physical, and optical properties as diamonds mined from the earth.

Grown from a tiny carbon "seed," these stones are subjected to processes that mimic nature, resulting in a crystal that is chemically identical to its mined counterpart. Without specialized gemological equipment, they are indistinguishable.

The Role of Technology in Creation

The value of a lab diamond is tied directly to the technology used to create it. Processes like High Pressure/High Temperature (HPHT) or Chemical Vapor Deposition (CVD) require immense energy, advanced machinery, and scientific expertise.

This manufacturing process sets the price. It's a technological cost, not a cost based on geological rarity.

The Core Difference in Value: Scarcity vs. Technology

The fundamental reason for the price gap between natural and lab-grown diamonds lies in two completely different economic models.

Natural Diamonds: A Market of Scarcity

The value of natural diamonds is built on their geological rarity and the significant cost and effort of mining them. For decades, this supply has been tightly controlled, creating a market where price is dictated by perceived scarcity.

Lab Diamonds: A Market of Production

Lab diamonds are a product of technology. Their value is based on the cost of production, including electricity, equipment, and labor. Like most technology, these processes tend to become more efficient and less expensive over time.

What This Means for Future Prices

Because their price is tied to technology, it is widely predicted that the cost of lab-grown diamonds will continue to decrease as production methods improve and scale. This is the opposite of the market dynamic for natural diamonds.

Understanding the Trade-offs: Price vs. Resale Value

Choosing a lab diamond involves a clear set of trade-offs that every buyer should understand. It is a decision about where you want your "value" to be.

The Immediate Benefit: Lower Purchase Price

The most compelling advantage is the cost. Lab-created diamonds typically cost 60% to 85% less than natural diamonds of comparable carat, cut, color, and clarity.

This allows you to either save a significant amount of money or purchase a much larger and higher-quality stone for the same budget.

The Long-Term Reality: Poor Resale Value

No diamond, natural or lab-grown, should be considered a strong financial investment. Both have poor resale value compared to their retail price.

However, the resale value for lab-grown diamonds is exceptionally low and is expected to decline further as their production costs fall. You are buying a beautiful product for personal enjoyment, not an asset.

Ethical and Environmental Considerations

Beyond price, lab diamonds offer significant value for buyers concerned with ethics and environmental impact. They are, by definition, conflict-free and avoid the massive ecological disruption associated with traditional mining operations.

How to Decide What's Right for You

The "worth" of a lab diamond is entirely dependent on your personal priorities. The right choice becomes clear when you define your primary goal.

- If your primary focus is maximizing carat size and quality for your budget: A lab-created diamond offers exceptional value and is the logical choice.

- If your primary focus is the tradition and perceived long-term store of value: A natural diamond is the conventional choice, though its investment potential is often overstated.

- If your primary focus is minimizing ethical and environmental impact: A lab-created diamond is the superior option.

Ultimately, you are purchasing a symbol and a beautiful object, and a lab diamond delivers the identical visual and physical experience for a fraction of the cost.

Summary Table:

| Aspect | Lab-Created Diamond | Natural Diamond |

|---|---|---|

| Purchase Price | 60-85% lower | Significantly higher |

| Resale Value | Very low, expected to decline | Poor, but higher than lab-grown |

| Primary Value | Budget maximization, ethics | Perceived rarity, tradition |

| Origin | Technological production | Geological scarcity |

Ready to equip your laboratory with precision and reliability? At KINTEK, we specialize in providing high-quality lab equipment and consumables to support your research and analysis needs. Whether you're in materials science, gemology, or quality control, our products deliver the accuracy and durability you require. Contact our experts today to find the perfect solution for your lab!

Visual Guide

Related Products

- CVD Diamond for Thermal Management Applications

- Laboratory CVD Boron Doped Diamond Materials

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- CVD Diamond Domes for Industrial and Scientific Applications

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- Are lab-grown diamonds comparable to natural diamonds? Discover the Science Behind the Sparkle

- What is the future of CVD diamond? Unlocking Next-Gen Electronics & Thermal Management

- Are CVD diamonds better than HPHT? The Real Truth About Lab-Grown Diamond Quality

- What is the main difference between CVD and natural diamond? Origin, Purity, and Value Explained

- Is lab-grown diamond legal? Yes, and here's why they're a legitimate choice