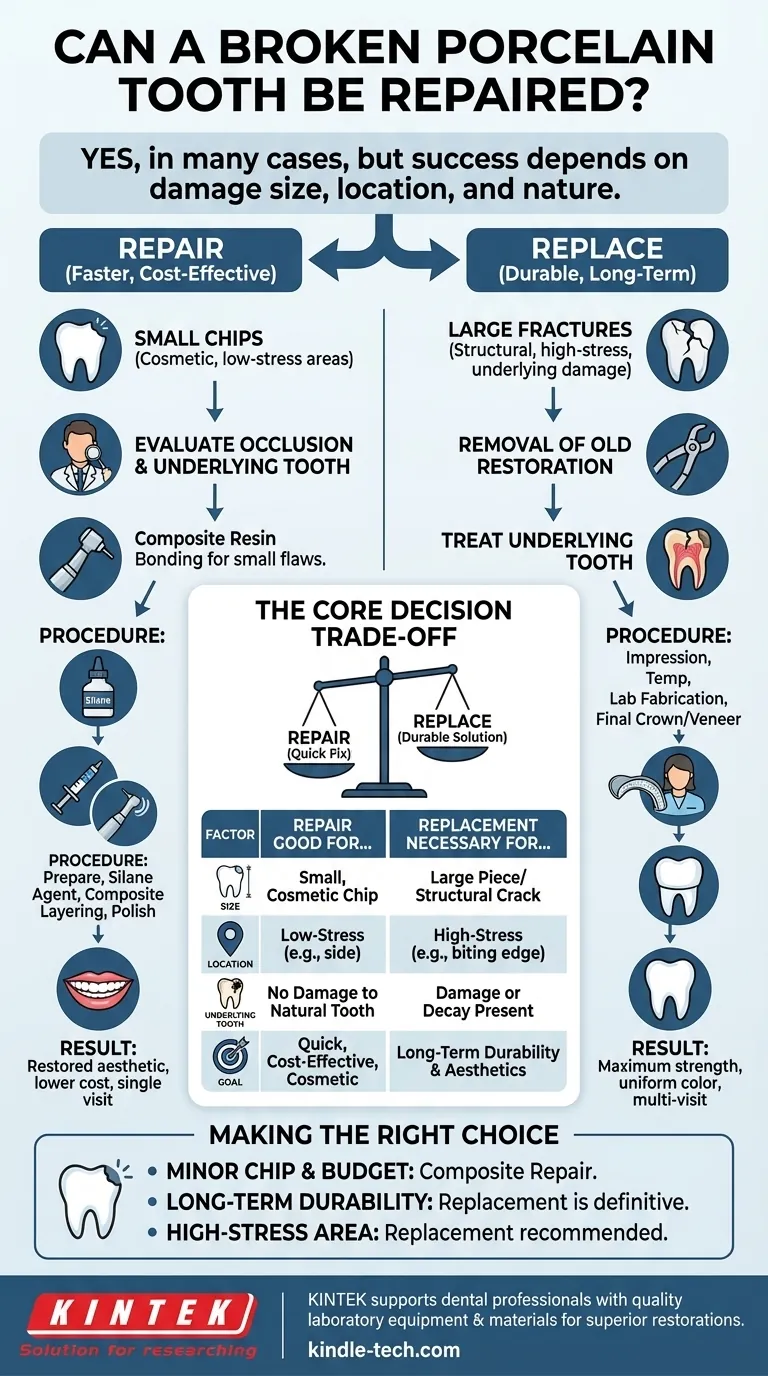

Yes, in many cases, a broken porcelain tooth can be repaired. The success and advisability of a repair, however, depend entirely on the size, location, and nature of the damage. For small, cosmetic chips, a direct repair is often a viable solution, but for larger, structural fractures, replacement is almost always the necessary course of action.

The core decision is a trade-off: repairing a broken porcelain restoration is a faster, less expensive fix, while replacing it is a more durable, predictable, and long-term solution. Understanding the nature of the damage is key to choosing the right path.

Evaluating the Damage: When is Repair an Option?

The first step your dentist will take is to assess the restoration to determine if you are a candidate for repair. The answer isn't always straightforward and depends on several critical factors.

Small Chips and Cosmetic Flaws

Minor chips, especially those on surfaces not subject to heavy biting forces, are the best candidates for repair. These are often purely aesthetic issues that don't compromise the overall strength of the crown or veneer.

In these situations, a dentist can use composite resin bonding to fill in the chip. This is the same durable, tooth-colored material used for modern fillings.

The Importance of Location

The location of the fracture is just as important as its size. A small chip on the biting edge of a front tooth is under constant stress and is far more likely to fail after repair than a similar-sized chip on the side of a molar.

Your dentist will evaluate the "occlusion," or how your teeth come together, to predict the forces the repaired area will have to endure.

Damage to the Underlying Tooth

If the break in the porcelain also involves damage to the natural tooth structure underneath, a simple repair is off the table. The priority shifts to treating the underlying tooth.

This scenario almost always requires the removal of the old restoration to address any decay or fracture in the natural tooth, followed by the creation of a new crown or veneer.

Large or Structural Fractures

If a large piece of the restoration has broken off or if the crown is cracked through, its structural integrity is compromised. Attempting to "glue" a large piece back on or patch a significant crack is highly unreliable.

In these cases, replacement is the only predictable and safe long-term solution. A repaired but structurally weak crown is at high risk of complete failure, which could lead to swallowing the broken piece or damaging adjacent teeth.

The Repair Process: A Step-by-Step Look

When repair is deemed appropriate, the procedure is a meticulous, multi-step process designed to create the strongest possible bond between the old porcelain and the new composite resin.

Preparing the Porcelain Surface

First, the dentist will carefully roughen the chipped porcelain surface. This is often done with a fine diamond bur or a micro-etcher, which is like a miniature sandblaster. This creates microscopic texture for the bonding material to grip.

Sometimes, a chemical agent like hydrofluoric acid may be used to further etch the porcelain for a superior bond.

Applying a Silane Coupling Agent

This is a critical chemical step. A silane coupling agent is applied to the etched porcelain. This agent acts as a double-sided adhesive, creating a powerful chemical bridge between the inorganic porcelain and the organic composite resin that will be applied next.

Layering the Composite Resin

The dentist then skillfully applies the tooth-colored composite resin in small layers. They will use various shades and opacities to perfectly match the color and translucency of your existing porcelain restoration. Each layer is hardened using a special curing light.

Polishing for a Seamless Finish

Finally, the dentist will shape and polish the hardened composite. This final step is crucial for creating a smooth, seamless surface that blends invisibly with the rest of the tooth and feels natural to your tongue.

Understanding the Trade-offs: Repair vs. Replacement

Choosing between repair and replacement involves weighing cost, time, and longevity.

Durability and Lifespan

A repaired spot is the weak link in the restoration. The bond between composite resin and porcelain, while strong, is not as durable as a single, solid piece of ceramic. The repaired area is more susceptible to chipping or breaking again in the future.

A new crown or veneer is fabricated as a single, monolithic piece in a lab, making it significantly stronger and more durable than a patched-up repair.

Aesthetics and Staining

While a skilled dentist can achieve a nearly invisible repair initially, the composite resin material may stain at a different rate than the porcelain over the years. This can eventually lead to a visible patch.

A new restoration will be perfectly uniform in color and will stain evenly over its entire surface.

Cost and Time

Repair is the clear winner in terms of immediate cost and time. A repair is typically completed in a single appointment and costs significantly less than a full replacement.

Replacement is a multi-step process, usually requiring at least two appointments: one for preparation and impressions, and a second for fitting the final crown. This makes it more expensive and time-consuming.

Making the Right Choice for Your Situation

Consulting with your dentist is essential, but understanding these principles will empower you to have a more productive conversation.

- If your primary focus is a quick, cost-effective fix for a minor cosmetic chip: A direct composite repair is an excellent and appropriate solution.

- If your primary focus is the best long-term durability and aesthetics: Replacement is the definitive and most reliable choice, especially if the damage is more than a tiny chip.

- If the damage is on a high-stress biting surface: You should strongly consider replacement, as a repair is at high risk of failing under normal chewing forces.

Ultimately, a thorough evaluation by a dental professional will provide the definitive plan to restore both the function and appearance of your tooth.

Summary Table:

| Factor | Repair is a Good Option When... | Replacement is Necessary When... |

|---|---|---|

| Size of Damage | Small, cosmetic chip | Large piece broken off or structural crack |

| Location | Low-stress area (e.g., side of tooth) | High-stress area (e.g., biting edge) |

| Underlying Tooth | No damage to the natural tooth underneath | Damage or decay is present on the natural tooth |

| Goal | Quick, cost-effective cosmetic fix | Long-term durability and predictable aesthetics |

Restore Your Smile with Confidence

Facing a broken crown or veneer? Making the right choice between repair and replacement is crucial for your oral health and smile's longevity. KINTEK specializes in providing the high-quality dental laboratory equipment and materials that professionals rely on for creating durable, aesthetically perfect porcelain restorations.

Whether your dentist is performing a precise composite repair or crafting a new, stronger crown, the right tools make all the difference. Let us help your dental professional provide you with the best possible care.

Contact our experts today to learn more about the products that support superior dental outcomes. #ContactForm

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Dental Porcelain Sintering Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is a dental furnace? The Precision Oven for Creating Strong, Lifelike Dental Restorations

- If a dental laboratory's ceramic restorations lack ideal aesthetics, what is the first step? Calibrate Your Furnace.

- What are dental ceramics made of? A Guide to Composition, Strength, and Aesthetics

- What is a dental burnout furnace? A Precision Tool for Flawless Dental Restorations

- What are the white spots on zirconia after sintering? A Guide to Diagnosing and Preventing Defects

- What is the strongest dental ceramic? Zirconia Leads in Strength, But Is It Right for Your Case?

- How do dental ceramic ovens process materials? Master Heat and Pressure for Perfect Restorations

- What is the firing temperature of dental ceramics? A Guide to Precise Thermal Processing