While technically possible in some limited scenarios, a heat press is not a substitute for a laminator. A heat press applies direct, static heat and pressure, which is fundamentally different from the rolling heat and pressure of a laminator. Using a heat press for lamination risks melting the plastic, trapping air bubbles, and potentially damaging both your document and the press itself.

A heat press is designed to transfer graphics onto a surface, while a laminator is engineered to encapsulate a document within plastic. While both use heat, their mechanisms are built for different materials and outcomes, making them poor substitutes for one another.

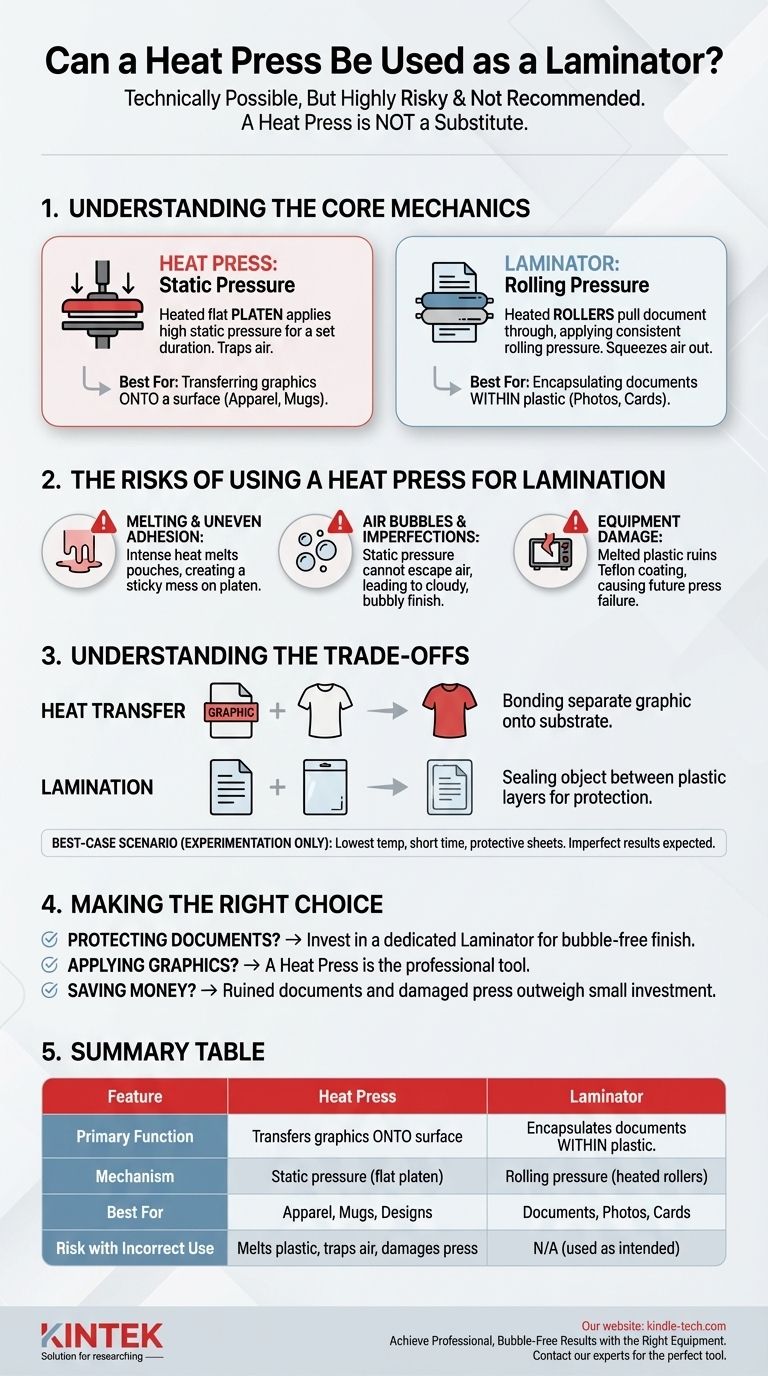

Understanding the Core Mechanics: Heat Press vs. Laminator

To understand the limitations, you must first understand how each machine operates. Though they both use heat, their application method is fundamentally different and tailored to a specific task.

How a Heat Press Works

A heat press uses a heated flat plate, called a platen, to clamp down onto a material. Its purpose is to apply a specific temperature and high pressure for a set duration.

This process is ideal for bonding things to a surface, such as plastisol transfers, vinyl graphics, or sublimation inks onto fabric or other substrates. The high, direct pressure ensures a permanent bond.

How a Laminator Works

A laminator uses a set of heated rollers to pull a document sealed inside a plastic pouch through the machine.

The rollers apply consistent heat and pressure simultaneously, squeezing air out from the center towards the edges as the pouch moves. This progressive sealing action is critical for creating a clear, bubble-free finish.

The Critical Difference: Platens vs. Rollers

The core difference is static pressure versus rolling pressure.

A heat press platen clamps down at once, trapping any air between the document and the laminating pouch. A laminator's rollers systematically push this air out, ensuring a smooth, airtight seal that a flat press simply cannot replicate.

The Risks of Using a Heat Press for Lamination

Attempting to laminate with a heat press is an "off-label" use that introduces significant risks to your project and your equipment.

Melting and Uneven Adhesion

Laminating pouches are made from a thin plastic that is designed for the specific, even heat of a laminator's rollers. The intense, direct heat from a press platen can easily overwhelm and melt the pouch.

This often results in a sticky, molten mess on your heat press and a ruined document. The heat is often too inconsistent across the large platen for such a delicate task.

Air Bubbles and Imperfections

Because a heat press cannot squeeze air out, bubbles and cloudiness are almost guaranteed. This "orange peel" effect defeats the purpose of lamination, which is to create a clear, professional, and protective layer.

Damage to Your Equipment

Melted laminating plastic is extremely difficult to remove from a heat press platen. It can ruin the Teflon coating, leading to uneven heating and causing future apparel-pressing projects to stick and fail. While a protective sheet can help, it doesn't eliminate the risk.

Understanding the Trade-offs

While not recommended, it's important to understand the context where one might even consider this method.

The Distinction: Heat Transfer vs. Lamination

The process of using a heat press for plastisol transfers or vinyl is fundamentally a heat transfer process. You are bonding a separate graphic layer onto a substrate like a t-shirt.

Lamination, by contrast, is an encapsulation process. You are completely sealing an object between two layers of plastic to protect it from all sides. These are distinct goals requiring different tools.

The Best-Case Scenario: Experimentation Only

If you must attempt this, do so only on a small, non-critical item you are willing to lose. Use the lowest possible temperature setting, very short pressing times, and always place the laminating pouch between two protective Teflon or parchment paper sheets.

Even then, expect an imperfect result. This should be viewed as an experiment, not a reliable production method.

Making the Right Choice for Your Goal

Using the correct tool is the most efficient path to a professional result. Your decision should be based on your primary objective.

- If your primary focus is protecting documents with a clear, bubble-free finish: Invest in a dedicated laminating machine. Even inexpensive personal laminators will produce vastly superior results and eliminate risk.

- If your primary focus is applying graphics and designs to apparel and other goods: A heat press is the correct professional tool for this specific job.

- If your primary focus is saving money by using one tool for everything: Recognize that the potential cost of a ruined document or a damaged heat press platen far outweighs the small investment in a proper laminator.

Ultimately, using a tool for its intended purpose ensures quality, prevents damage, and produces the professional results you are aiming for.

Summary Table:

| Feature | Heat Press | Laminator |

|---|---|---|

| Primary Function | Transfers graphics onto a surface | Encapsulates documents within plastic |

| Mechanism | Static pressure from a flat platen | Rolling pressure from heated rollers |

| Best For | Apparel, mugs, plates (applying designs) | Documents, photos, cards (protection) |

| Risk with Incorrect Use | Melts plastic, traps air bubbles, damages press | N/A (used as intended) |

Achieve Professional, Bubble-Free Results with the Right Equipment

Understanding the distinct roles of a heat press and a laminator is key to protecting your projects and your investment. While a heat press excels at applying graphics, a dedicated laminator is essential for clear, protective encapsulation.

KINTEK specializes in providing reliable laboratory and workshop equipment. Whether your needs involve precise heat application for materials testing or protective document sealing, we have the expertise and products to support your work.

Don't risk damaging your materials—contact our experts today to find the perfect tool for your specific application!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Anti-Cracking Press Mold for Lab Use

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

People Also Ask

- Which features of vacuum hot pressing equipment are utilized by the dual-step vacuum hot press process? Optimize AlMgTi

- What is hot press forging? Creating Complex, High-Strength Metal Components

- Why is a heated laboratory hydraulic press necessary for composite laminates? Achieve Void-Free Structural Integrity

- What is hot press moulding? Achieve Superior Density and Complex Shapes with Heat and Pressure

- How does hot pressing work? Achieve Maximum Density for Advanced Materials