Yes, absolutely. An induction furnace is not only capable of melting aluminum but is often a highly effective and preferred method for the task. This technology is widely used for melting a variety of non-ferrous metals, including aluminum, copper, and brass, as well as all types of ferrous metals like iron and steel.

The core takeaway is that induction furnaces are a modern, efficient, and clean technology for melting aluminum. They offer significant advantages in speed, energy efficiency, and reduced material loss compared to older furnace types.

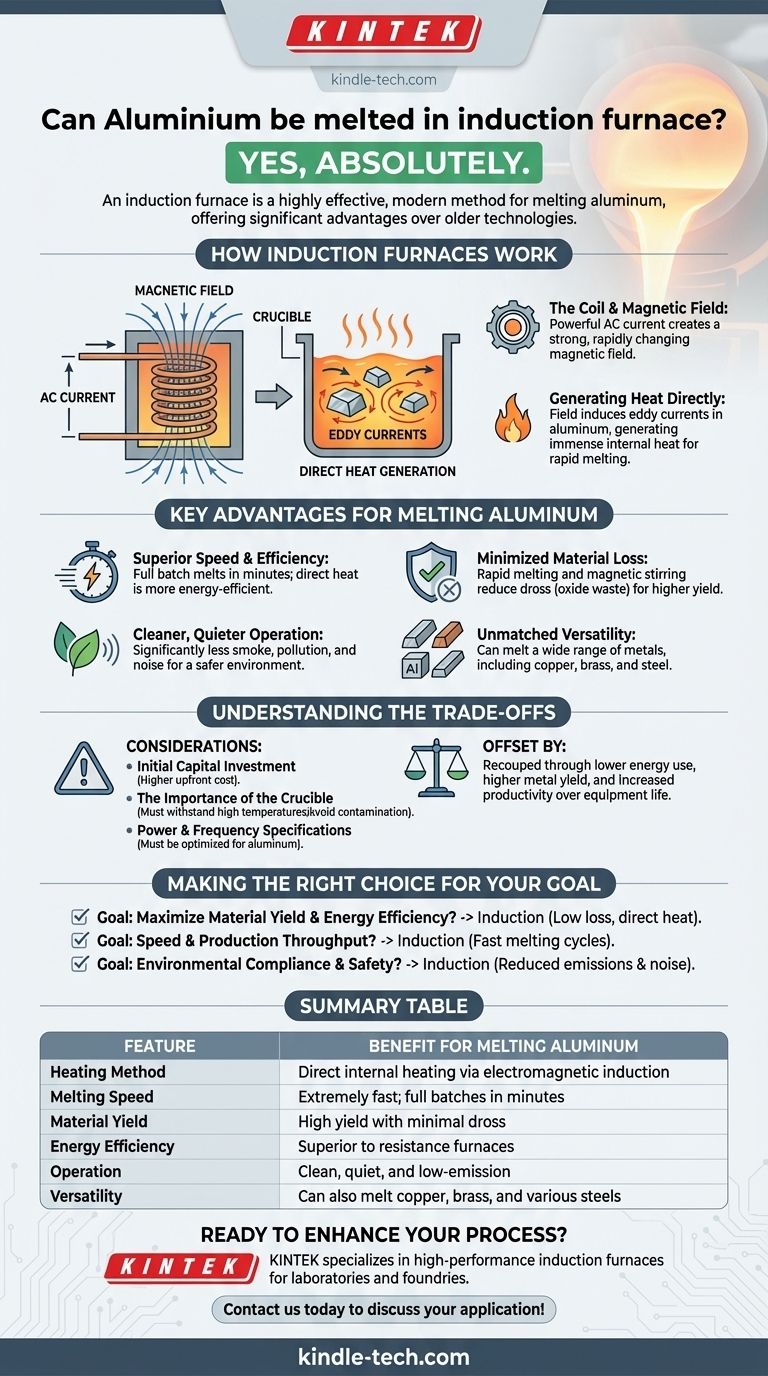

How Induction Furnaces Work

An induction furnace operates on the principle of electromagnetic induction to generate heat directly within the metal itself, rather than using an external flame or heating element.

The Coil and Magnetic Field

The core of the furnace is a coil made from a conductive material like copper. A powerful alternating electrical current is passed through this coil, which creates a strong, rapidly changing magnetic field around and within the furnace crucible.

Generating Heat Directly in the Metal

When aluminum or another conductive metal is placed inside this magnetic field, the field induces powerful electrical currents (known as eddy currents) within the metal. The metal's natural resistance to the flow of these currents generates immense heat, quickly raising its temperature to its melting point.

Key Advantages for Melting Aluminum

Choosing an induction furnace for aluminum offers several distinct operational and financial benefits over alternative technologies like resistance or power-frequency furnaces.

Superior Speed and Efficiency

Induction furnaces are remarkably fast. A small furnace can melt a full batch of metal in just a few minutes, drastically increasing throughput. They are also more energy-efficient than traditional resistance furnaces because the heat is generated directly inside the material being melted.

Minimized Material Loss

One of the most significant advantages is the reduction in aluminum loss. The rapid melting process and the inherent stirring action of the magnetic field minimize the amount of metal that turns into dross (oxide waste), ensuring a higher yield from your raw material.

A Cleaner, Quieter Operation

Compared to older technologies, modern induction furnaces produce significantly less smoke, pollution, and noise. This creates a safer and more compliant working environment.

Unmatched Versatility

The same induction furnace can be used to melt a wide range of materials, from aluminum and copper to various types of steel and even superalloys. This flexibility makes it a valuable asset in foundries and recycling operations that handle multiple metal types.

Understanding the Trade-offs

While highly effective, there are practical considerations to keep in mind when implementing induction melting technology.

Initial Capital Investment

The upfront cost of an induction furnace system can be higher than that of simpler, older furnace types. However, this initial investment is often recouped through lower energy consumption, higher metal yield, and increased productivity over the life of the equipment.

The Importance of the Crucible

The crucible, which holds the molten metal, is a critical component. It must be made of a material, such as a refractory ceramic, that can withstand extreme temperatures and is compatible with the specific metal being melted to avoid contamination.

Power and Frequency Specifications

Different metals and melt sizes benefit from different operating frequencies. The furnace's power and frequency must be correctly specified for the intended application to ensure optimal performance and efficiency when melting materials like aluminum.

Making the Right Choice for Your Goal

Selecting the right melting technology depends entirely on your operational priorities.

- If your primary focus is maximizing material yield and energy efficiency: Induction is an excellent choice due to its low metal loss and direct, rapid heating method.

- If your primary focus is speed and production throughput: The fast melting cycles of an induction furnace make it ideal for high-volume operations.

- If your primary focus is environmental compliance and workplace safety: The reduced emissions and lower noise levels of induction furnaces offer clear advantages over fuel-fired alternatives.

Ultimately, using an induction furnace is a proven and highly advantageous method for melting aluminum efficiently and cleanly.

Summary Table:

| Feature | Benefit for Melting Aluminum |

|---|---|

| Heating Method | Direct internal heating via electromagnetic induction |

| Melting Speed | Extremely fast; full batches in minutes |

| Material Yield | High yield with minimal dross (oxide waste) |

| Energy Efficiency | Superior to resistance furnaces |

| Operation | Clean, quiet, and low-emission |

| Versatility | Can also melt copper, brass, and various steels |

Ready to enhance your aluminum melting process?

KINTEK specializes in high-performance lab equipment and consumables, including induction furnaces designed for the precise needs of laboratories and foundries. Our solutions deliver the speed, efficiency, and material yield you need to stay competitive.

Contact us today to discuss how our induction furnaces can benefit your specific application!

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- How does a quartz tube vacuum furnace contribute to the crystallization process of Ag-doped Li-argyrodite electrolytes?

- Why is a quartz tube furnace utilized in the thermal oxidation of MnCr2O4 coatings? Unlock Precise Selective Oxidation

- How to clean a tube furnace? A Step-by-Step Guide for Safe and Effective Maintenance

- What materials are used for the tubes in tube furnaces? A Guide to Selecting the Right Tube for Your Process

- What is the technical value of using a quartz tube reaction chamber for static corrosion testing? Achieve Precision.