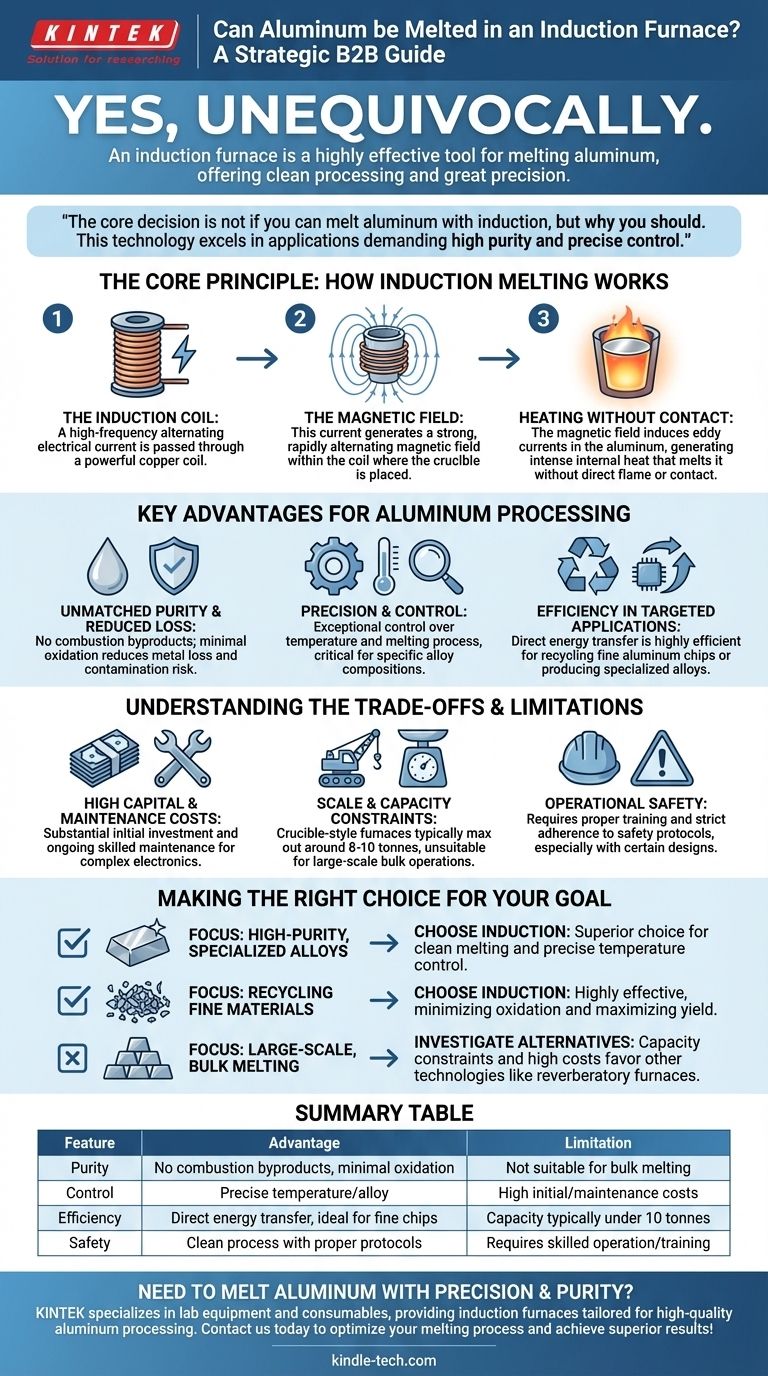

Yes, unequivocally. An induction furnace is a highly effective tool for melting aluminum and a wide range of other non-ferrous and ferrous metals. Its ability to generate high temperatures through electromagnetic induction allows it to process materials cleanly and with great precision.

The core decision is not if you can melt aluminum with induction, but why you should. This technology excels in applications demanding high purity and precise control, but its significant costs and capacity limits make it a specialized choice rather than a solution for bulk melting.

The Core Principle: How Induction Melting Works

Understanding how an induction furnace operates is key to appreciating its specific advantages for materials like aluminum. The process is fundamentally different from traditional fuel-fired methods.

The Induction Coil

An induction furnace uses a powerful coil, typically made of copper, through which a high-frequency alternating electrical current is passed.

The Magnetic Field

This electrical current generates a strong, rapidly alternating magnetic field in the space within the coil, where the crucible containing the aluminum is placed.

Heating Without Contact

The magnetic field induces powerful electrical currents (eddy currents) directly within the aluminum itself. The metal's natural electrical resistance causes these currents to generate intense heat, melting it from the inside out without any external flame or heating element touching it.

Key Advantages for Aluminum Processing

Choosing induction technology for melting aluminum is a strategic decision, often driven by the need for superior metal quality and process control.

Unmatched Purity and Reduced Metal Loss

Because no combustion byproducts are created, the risk of contaminating the aluminum with hydrogen or other impurities is virtually eliminated. This clean melting process also significantly reduces metal loss that would otherwise occur from oxidation in a direct-fire furnace.

Precision and Control

Induction systems offer exceptional control over temperature and the melting process. This precision is critical when producing specific aluminum alloys where the final composition must meet exacting standards.

Efficiency in Targeted Applications

While not designed for massive volumes, the direct transfer of energy into the metal makes induction highly efficient for its intended scale, particularly for recycling fine aluminum chips or producing specialized alloys.

Understanding the Trade-offs and Limitations

To make an informed decision, you must weigh the clear benefits against significant practical and financial constraints. An induction furnace is not a universal solution.

High Capital and Maintenance Costs

The initial investment for an induction furnace system is substantial. Furthermore, the high-power electronics and specialized components require ongoing, skilled maintenance, adding to the total cost of ownership.

Scale and Capacity Constraints

Crucible-style induction furnaces, common for non-ferrous metals, typically have a maximum capacity of around 8-10 tonnes. This makes them fundamentally unsuitable for large-scale production or bulk melting operations.

Operational Safety

The design of some induction furnaces, particularly top-loading models, can pose safety risks during operation. Proper training and strict adherence to safety protocols are non-negotiable.

Making the Right Choice for Your Goal

Your specific objective determines whether an induction furnace is the right tool for the job.

- If your primary focus is producing high-purity, specialized aluminum alloys: The clean melting and precise temperature control of an induction furnace make it the superior choice.

- If your primary focus is recycling fine materials like aluminum chips: Induction is highly effective, minimizing oxidation and maximizing your yield of reusable metal.

- If your primary focus is large-scale, bulk aluminum melting: The capacity constraints and high costs mean you should investigate other technologies, such as reverberatory furnaces.

Ultimately, selecting the right melting technology is about aligning the equipment's unique capabilities with your specific operational and financial goals.

Summary Table:

| Feature | Advantage | Limitation |

|---|---|---|

| Purity | No combustion byproducts; minimal oxidation | Not suitable for bulk melting |

| Control | Precise temperature and alloy composition | High initial and maintenance costs |

| Efficiency | Direct energy transfer; ideal for fine chips | Capacity typically under 10 tonnes |

| Safety | Clean process with proper protocols | Requires skilled operation and training |

Need to melt aluminum with precision and purity?

KINTEK specializes in lab equipment and consumables, providing induction furnaces tailored for high-quality aluminum processing. Whether you're developing specialized alloys or recycling fine materials, our solutions deliver unmatched control and efficiency. Contact us today to optimize your melting process and achieve superior results!

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Induction Melting Spinning System Arc Melting Furnace

People Also Ask

- What are the advantages of induction melting? Achieve Faster, Cleaner, and More Controlled Metal Melting

- How does an induction heating furnace work? Discover the Power of Internal, Contactless Heating

- What is the function of a vacuum induction melting furnace? Essential Guide for High-Purity FeCrAl Alloy Production

- What is the benefit of induction heating? Unlock Unmatched Speed, Precision, and Cleanliness

- How does vacuum induction melting improve nickel-base alloy properties? Boost Corrosion Resistance for Reactor Safety

- Who invented induction furnace? Discover the Pioneers Behind Modern Metallurgy

- What is high frequency induction heating used for? Achieve Precise Surface Hardening & Brazing

- Why does an induction furnace blast? Prevent Catastrophic Steam Explosions in Your Foundry