Yes, an induction furnace is not only capable of melting steel, it is a primary technology used for this purpose across the globe. It excels at melting various types of steel, iron, and other metals by using electromagnetic principles to generate intense heat directly within the material itself, making it a highly efficient and controlled process.

An induction furnace melts steel by using a powerful, alternating magnetic field to induce electrical currents inside the metal. The steel's natural resistance to these currents generates rapid, precise heat, allowing it to reach its melting point in a clean and controlled environment.

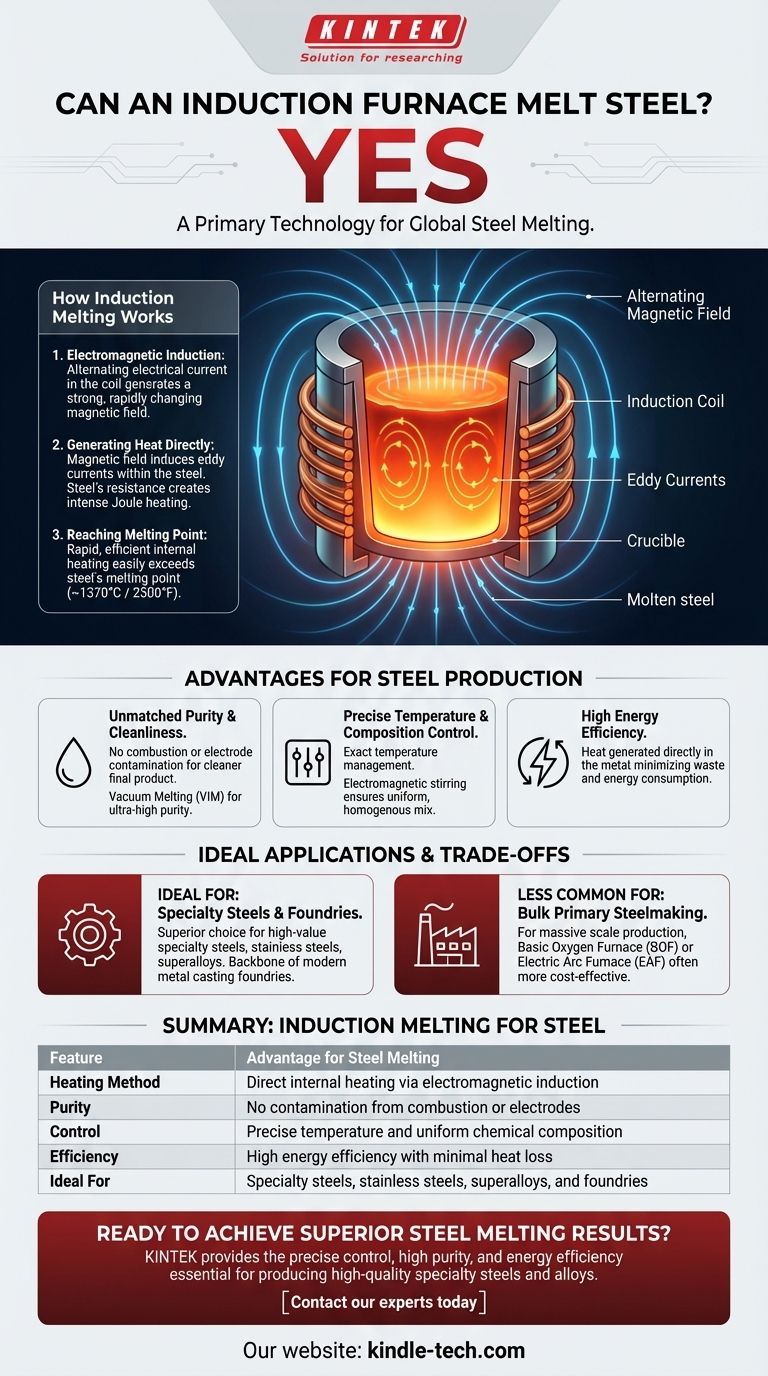

How Induction Melting Works for Steel

To understand why this method is so effective, we must look at the core physics involved. It is a fundamentally different approach than a conventional fuel-fired furnace.

The Principle of Electromagnetic Induction

An induction furnace uses a coil of conductive material, typically copper, through which a powerful alternating electrical current is passed.

This current generates a strong, rapidly changing magnetic field in the space within the coil, which is where the crucible containing the steel is placed.

Generating Heat Directly in the Metal

The magnetic field penetrates the steel charge and induces smaller, circular electrical currents within the metal, known as eddy currents.

The steel has a natural electrical resistance. As these powerful eddy currents flow against this resistance, intense heat is generated through a process called Joule heating. The metal itself becomes its own heating element.

Reaching Steel's Melting Point

This internal heating is extremely rapid and efficient, easily allowing the furnace to reach and exceed the melting point of steel, which is approximately 1370°C (2500°F). The furnace can achieve the high temperatures required for even more demanding refractory metals and superalloys.

The Advantages of Induction for Steel Production

The unique heating method of an induction furnace provides several key advantages, particularly for producing high-quality and specialized steels.

Unmatched Purity and Cleanliness

Because the heat is generated within the steel, there are no combustion byproducts or electrodes to contaminate the melt. This results in a much cleaner final product.

For ultra-high-purity applications, vacuum induction melting (VIM) furnaces perform this process in a vacuum, preventing the molten steel from reacting with oxygen or nitrogen in the air.

Precise Temperature and Composition Control

The power supplied to the induction coil can be controlled with extreme precision, allowing for exact temperature management of the molten steel.

Furthermore, the magnetic field creates a natural electromagnetic stirring action within the molten bath. This ensures that alloying elements like chromium, nickel, or manganese are mixed thoroughly, leading to a perfectly uniform and homogenous chemical composition.

High Energy Efficiency

Induction melting is highly energy-efficient because heat is generated directly where it is needed—inside the metal. Far less energy is wasted heating the furnace walls or the surrounding environment compared to other methods.

Understanding the Trade-offs

While powerful, an induction furnace is not the universal solution for all steelmaking operations. Understanding its ideal applications is key.

Ideal for Specialty Steels and Foundries

The precision, cleanliness, and control of induction furnaces make them the superior choice for producing high-value specialty steels, stainless steels, and complex superalloys.

They are also the backbone of the modern metal casting foundry, where they melt scrap steel and other metals to produce high-quality castings with consistent properties.

Less Common for Bulk Primary Steelmaking

For producing millions of tons of basic carbon steel from raw materials (like iron ore), steel mills more commonly use a Basic Oxygen Furnace (BOF) or a large-scale Electric Arc Furnace (EAF).

While very large induction furnaces exist, EAFs are often more cost-effective for melting massive quantities of scrap steel for commodity-grade structural steel production. The choice depends on scale, input material, and the desired quality of the final product.

Making the Right Choice for Your Application

Selecting the correct melting technology requires aligning the furnace's strengths with your specific operational goal.

- If your primary focus is high-purity or specialty alloys: The induction furnace is the superior choice due to its cleanliness, lack of contamination, and precise compositional control.

- If your primary focus is operating a foundry or recycling scrap steel: The efficiency, speed, and electromagnetic stirring of an induction furnace make it an excellent tool for creating consistent, high-quality molten metal.

- If your primary focus is massive-scale production of basic steel from scrap: An Electric Arc Furnace (EAF) may be a more economical solution for handling the sheer volume required for commodity steel grades.

Ultimately, understanding the principle of induction empowers you to select the right melting technology for your specific quality and production goals.

Summary Table:

| Feature | Advantage for Steel Melting |

|---|---|

| Heating Method | Direct internal heating via electromagnetic induction |

| Purity | No contamination from combustion or electrodes |

| Control | Precise temperature and uniform chemical composition |

| Efficiency | High energy efficiency with minimal heat loss |

| Ideal For | Specialty steels, stainless steels, superalloys, and foundries |

Ready to achieve superior steel melting results?

An induction furnace from KINTEK provides the precise control, high purity, and energy efficiency essential for producing high-quality specialty steels and alloys. Our expertise in lab equipment and consumables ensures you get the right solution for your specific melting needs, whether for R&D or production.

Contact our experts today to discuss how an induction furnace can enhance your laboratory or foundry operations.

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vertical Laboratory Tube Furnace

People Also Ask

- What is vacuum arc melting technique? Discover the Precision of Vacuum Induction Melting

- What is the principle of vacuum induction melting? Achieve Ultra-High Purity Metals

- What types of metals are typically processed in a vacuum induction melting furnace? High-Purity Alloys for Critical Applications

- What principle is used to generate heat in a vacuum induction melting furnace? Achieve Clean, Efficient Metal Melting

- What is VIM in metallurgy? A Guide to Vacuum Induction Melting for High-Performance Alloys