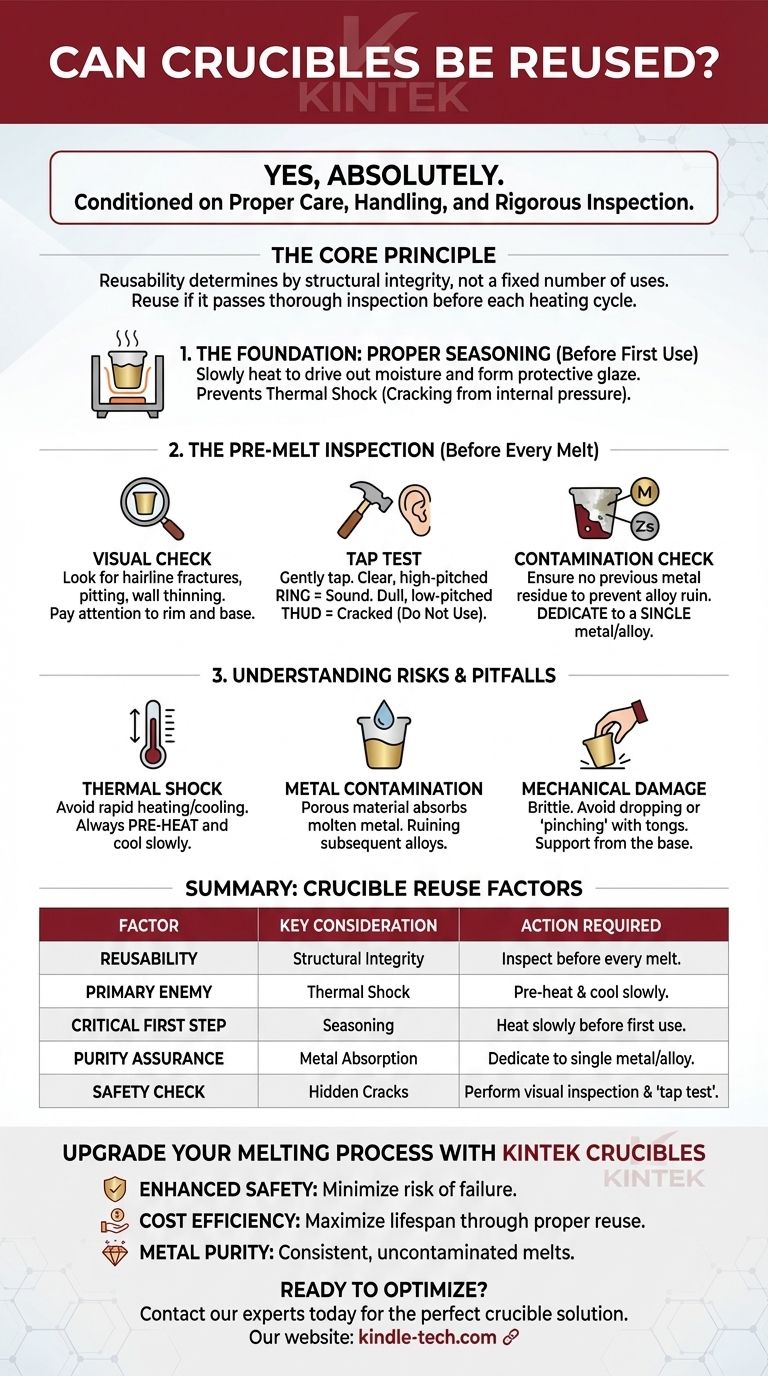

Yes, crucibles are absolutely designed to be reused. However, their reuse is entirely conditional on proper care, handling, and rigorous inspection before every single melt. Treating a crucible as a disposable item is unnecessarily expensive, but reusing a compromised crucible is a severe safety hazard that can lead to catastrophic failure.

The core principle is simple: A crucible's reusability is not determined by a fixed number of uses, but by its structural integrity. You can and should reuse a crucible as long as it passes a thorough inspection for cracks, erosion, and contamination before each heating cycle.

The Foundation of Reuse: Proper Seasoning

Before a crucible is ever used for melting, it must be seasoned. This is the single most important step in maximizing its lifespan and ensuring it can be reused safely.

What is Seasoning?

Seasoning is the process of slowly heating a new crucible to a designated temperature and then allowing it to cool slowly. This process drives out any residual moisture absorbed from the atmosphere during manufacturing and shipping.

For many graphite crucibles, this initial heating also forms a protective glaze on the surface, which helps resist oxidation and chemical attack from fluxes and molten metal.

Why It's Non-Negotiable

Skipping the seasoning process is the primary cause of premature crucible failure. Heating a crucible with trapped moisture causes the water to turn to steam, creating immense internal pressure that can crack or even shatter the crucible. This is a classic example of thermal shock.

The Pre-Melt Inspection: Your Safety Checklist

Before you place any metal inside, you must perform a quick but thorough inspection. This habit will save you money, prevent failed melts, and protect you from dangerous spills.

Visual Check for Cracks

Carefully inspect the entire crucible, inside and out, under good lighting. Look for hairline fractures, which often appear as thin, dark lines. Pay special attention to the rim and the base, as these are common stress points.

Look for Erosion and Pitting

Over time, molten metal and flux will slowly eat away at the crucible's interior wall. Check for significant pitting or areas where the wall has become noticeably thinner. If the crucible's original shape is compromised, it's time to retire it.

Perform the "Tap Test"

This is a simple auditory test for invisible cracks. Gently tap the side of the crucible with a small metal or wooden object. A structurally sound crucible will produce a clear, high-pitched ringing sound.

If you hear a dull, low-pitched "thud" instead of a ring, it almost certainly has a hidden crack. Do not use a crucible that fails the tap test.

Understanding the Risks and Common Pitfalls

Reusing a crucible safely means understanding what destroys it. The primary enemies are thermal shock, contamination, and physical damage.

The Danger of Thermal Shock

A crucible must always be heated and cooled slowly and evenly. Introducing a cold crucible to a blazing hot furnace or placing cold metal ingots into a red-hot crucible can cause it to crack instantly from thermal shock. Always pre-heat your crucible before charging it with metal.

The Problem of Metal Contamination

Crucibles, especially clay-graphite models, are porous. They absorb a small amount of the metal they hold when it's molten. If you melt aluminum in a crucible and then try to melt bronze in it, you will contaminate your bronze with aluminum, ruining the alloy.

For this reason, a crucible must be dedicated to a single metal or alloy for its entire lifespan. Label your crucibles clearly.

Mechanical Damage

Crucibles are strong but brittle. Dropping one or handling it aggressively with tongs can easily cause damage. Always use properly fitting tongs that support the crucible from its base, never "pinching" it from the top, which can crack the rim.

How to Apply This to Your Process

Your approach to reuse should be guided by a primary focus on safety and consistency.

- If your primary focus is safety: Make the visual inspection and the "tap test" a non-negotiable ritual before every single melt.

- If your primary focus is metal purity: Dedicate and clearly label each crucible for one specific metal or alloy to prevent cross-contamination.

- If your primary focus is extending crucible life: Always pre-heat your crucible, charge it correctly, and allow it to cool down slowly inside the furnace.

Treating your crucible with methodical care transforms it from a simple consumable into a reliable and long-lasting piece of critical equipment.

Summary Table:

| Crucible Reuse Factor | Key Consideration | Action Required |

|---|---|---|

| Reusability | Determined by structural integrity, not a fixed number of uses. | Inspect before every melt. |

| Primary Enemy | Thermal shock from rapid heating/cooling. | Always pre-heat and cool slowly. |

| Critical First Step | Seasoning to drive out moisture and form protective glaze. | Heat slowly before first use. |

| Purity Assurance | Crucibles absorb metal, leading to contamination. | Dedicate to a single metal/alloy. |

| Safety Check | Hidden cracks can cause catastrophic failure. | Perform visual inspection and 'tap test'. |

Upgrade Your Melting Process with KINTEK Crucibles

Your crucible is a critical piece of equipment, and its proper care directly impacts your safety, operational costs, and final product quality. At KINTEK, we specialize in supplying high-performance laboratory equipment and consumables, including durable crucibles designed for repeated, safe use when handled correctly.

Let us help you achieve:

- Enhanced Safety: Minimize the risk of dangerous crucible failure with our reliable products and expert guidance.

- Cost Efficiency: Maximize the lifespan of your investment through proper reuse practices.

- Metal Purity: Ensure consistent, uncontaminated melts with crucibles dedicated to your specific alloys.

Ready to optimize your lab's melting operations? Contact our experts today to discuss your specific needs and find the perfect crucible solution for your laboratory.

Visual Guide

Related Products

- Alumina Al2O3 Ceramic Crucible Semicircle Boat with Lid for Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Ceramics Alumina Al2O3 Crucible With Lid Cylindrical Laboratory Crucible

- Arc-Shaped Alumina Ceramic Crucible High Temperature Resistant for Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Ceramics Alumina Crucibles (Al2O3) for Thermal Analysis TGA DTA

- Engineering Advanced Fine Alumina Al2O3 Ceramic Crucible for Laboratory Muffle Furnace

People Also Ask

- What needs to be checked before using a crucible? A Guide to Safe and Effective High-Temperature Work

- What are the advantages of graphite crucibles? Achieve Superior High-Temperature Performance

- Why are Boron Nitride (BN) or Alumina crucibles preferred for Na-flux GaN growth? Optimize Your Crystal Yield

- What is the role of the stainless steel crucible in magnesium melting? Master AM60 Vacuum Process Parameters

- What is the function of a high-precision precursor crucible in ruthenium CVD? Master Uniform Thin Film Deposition

- How do you clean a melting crucible? Protect Your Crucible and Ensure Metal Purity

- What is the specific purpose of a heat-resistant crucible in a magnesium vacuum sublimation? Key Purification Insights

- What is the function of a water-cooled copper crucible? Ensure Purity in High-Entropy Alloy Melting